What is the function of each well water pressure system component?

What is the function of each well water pressure system component?

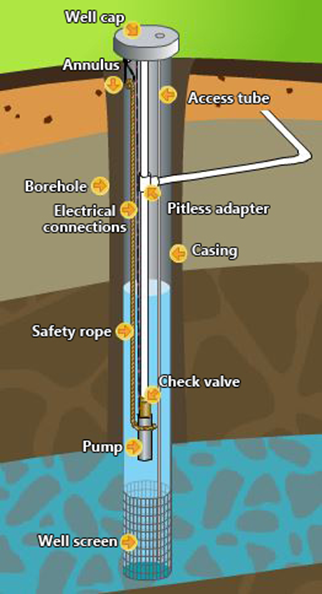

This article will provide an overview of a typical water well installation. It provides the information to enable those who are not familiar with the components, where they are located, and how they work together to enable your water pressure system to operate.

This article will provide an overview of a typical water well installation. It provides the information to enable those who are not familiar with the components, where they are located, and how they work together to enable your water pressure system to operate.

The goal is to help you identify the components required in a typical well installation, their purpose and function, and where they are installed in the system.

What is a water well system?

A water well pressure system is required for residential and commercial applications where a municipal or public water source is not available. First a water source needs to be located, then it is necessary to drill into the earth to reach the sustainable water supply. Once the water well is drilled, a submersible water pump is then installed within the well casing below the water level. The pump pushes the water from the well to the surface.

Each component in a typical well installation plays an integral role in a successful installation. All these components work together to ensure the water system works efficiently, and when installed properly will provide many years of trouble-free service.

Boshart Industries carries all the system components required to move water from the ground up, except for the submersible pump and the pressure tank.

This article we will provide a brief overview of each of the components in a typical well installation, including some basic installation guidelines. For more detailed specifications and installation instructions, refer to the additional training and reference materials.

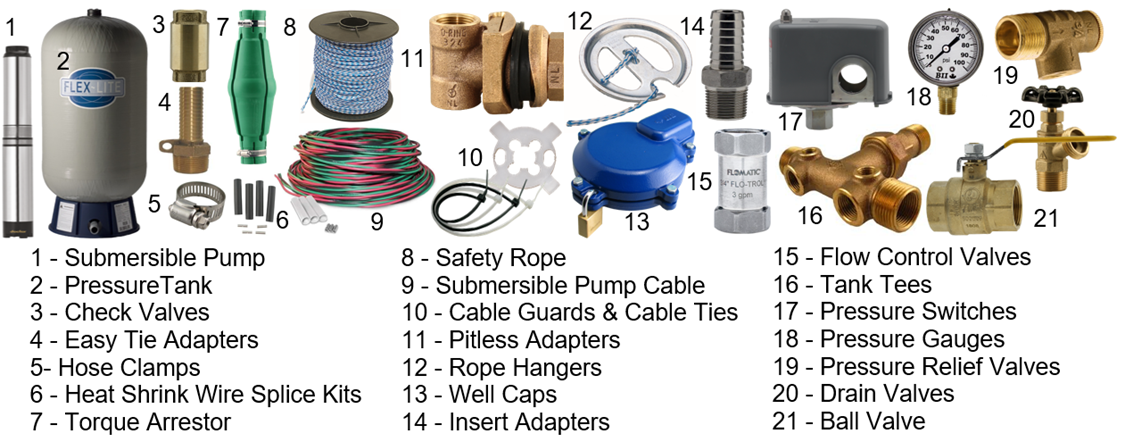

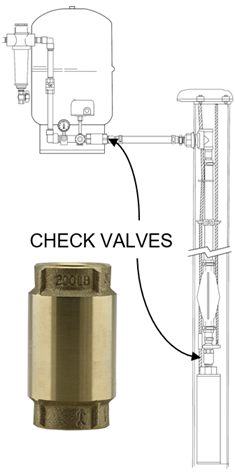

SUBMERSIBLE PUMP & PRESSURE TANK

SUBMERSIBLE PUMP & PRESSURE TANK

The function of the submersible pump is to push the water to the surface. Submersible pumps offer hydro efficiency as every gallon of water is utilized fully. It pumps more water, faster for it's power consumption. The submersible pump is installed underground inside a well casing, anywhere from 50 ft. to 1200 ft. underground.

The water pressure tanks should be sized to allow adequate water drawdown to prevent your water well pump from short cycling. This can shorten the life of the pump. Normal minimum run time should be 1 full minute between the well pump turning on and turning off.

Boshart Industries carries all the well system components required, except for the submersible pump and the pressure tank.

ADDITIONAL RESOURCES

https://support.boshart.com/how-can-i-tell-if-my-pressure-tank-is-waterlogged

https://support.boshart.com/can-sediment-filters-be-installed-between-the-pump-and-pressure-tank

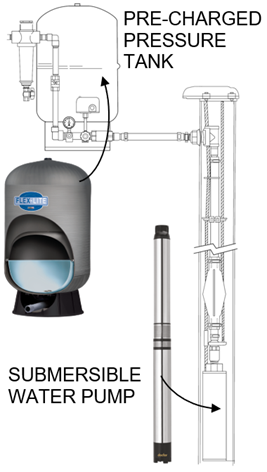

CHECK VALVES

CHECK VALVES

- The placement and number of check valves is determined by the depth of pump setting

- Provides protection for the pump

- Allows water to only travel in one direction

- Multiple check valves absorb some of the hydraulic water shocks

The placement and number of check valves required for a system is determined by the depth of the pump setting in the well. Installation of 200 feet or less requires one check valve on pump discharge and one on the surface of the well. Settings 200 feet or deeper may require multiple check valves at a maximum of 200-foot intervals. Check valves prevent water from reversing direction and draining back down the well when the pump stops. They carry the weight of the submersible pump, pipe, and the water in the riser pipe. Multiple check valves absorb some of the hydraulic water shocks associated with well water pumping which prevents damage due to water hammer which is often the cause of system failure. It is critical to follow the manufacturer’s installation instructions; failure to properly select the valve or to install using approved system design guidelines may void the warranty.

ADDITIONAL RESOURCES

https://support.boshart.com/how-to-install-a-submersible-pump-check-valve

https://support.boshart.com/what-is-the-cracking-pressure-of-a-17cvss-series-check-valve-1

https://support.boshart.com/what-is-the-cracking-pressure-of-a-17cvss-series-check-valve

https://support.boshart.com/what-is-the-weight-holding-capacity-for-flomatic-check-valves

https://support.boshart.com/what-is-the-cracking-pressure-of-a-flomatic-80-100-series-check-valves

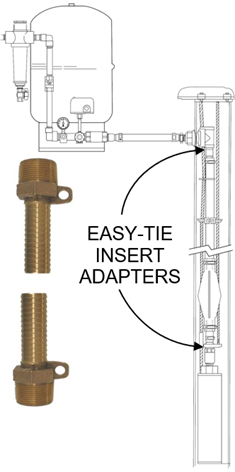

EASY-TIE ADAPTERS

EASY-TIE ADAPTERS

- Designed to prevent the loss of the submersible pump to the bottom of the well

- The first adapter is threaded into the check valve at the discharge of the submersible pump

- The second adapter is threaded into the pitless adapter

Easy Tie insert adapters thread into the discharge on the check valve at the submersible pump and inserts into the poly riser pipe. The second adapter is threaded into the pitless adapter at the well head to connect to the poly riser pipe. The lug with a hole, also referred to as a “rope eye”, provides an easy means to securely fasten the safety rope or cable. This secures the submersible pump to the well head in case of a pipe failure or if the insert fitting should pull out of the poly pipe. Boshart adapters are available in bronze and come in 1” and 1-1/4” sizes in straight and reducing configurations.

ADDITIONAL RESOURCES

https://support.boshart.com/what-type-of-poly-pipe-are-insert-fittings-designed-to-work-with

https://support.boshart.com/pressure-temperature-ratings-for-bronze-insert-fittings

https://support.boshart.com/pressure-temperature-ratings-for-304-stainless-steel-insert-fittings

https://support.boshart.com/insert-fitting-pull-off-resistance-testing

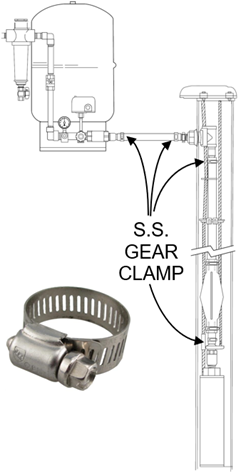

HOSE CLAMPS

HOSE CLAMPS

- Double clamping eliminates pull-off

- High torque capability provides a watertight seal every time

- Use All 300 Stainless Steel clamps for maximum corrosion resistance

Boshart worm gear drive general purpose hose clamps are designed for sealing poly pipe to barbed insert fittings and makes a positive watertight seal so the system will not leak. They compress the poly pipe into the serrations on the insert adapter to ensure a pull-off proof connection. In a water well installation or for direct burial of water lines, where maximum corrosion resistance is required, only the best All 300 Grade Stainless Steel Clamps are to be used to ensure that the clamp will last the lifetime of the system.

For maximum corrosion resistance use only the best 87 series All 300 Grade Stainless Steel Clamps for water well, direct burial applications.

ADDITIONAL RESOURCES

https://support.boshart.com/my-gear-clamp-has-magnetism-is-it-stainless-steel

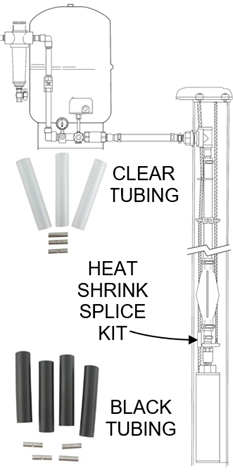

HEAT SHRINK WIRE SPICE KITS

HEAT SHRINK WIRE SPICE KITS

- Used for underwater electrical connections between the pump motor and cable

- Reduces the risk of damaging the splice

Boshart heat shrink splice kits are used for the underwater electrical connection between the leads on the pump motor and the pump cable. The connection is made by cutting the cables in a staggered position to minimize the cable outer diameter after completion. This is important to reduce the risk of damaging the splice due to abrasion when lowering the pump into the well. Each conductor is spliced by using a small metal connector, called a stakon, which accepts a wire into each end. Additional information on making proper splices is available in the additional training and reference materials.

ADDITIONAL RESOURCES

https://support.boshart.com/how-do-i-select-a-heat-shrink-splice-kit

https://support.boshart.com/are-the-tubes-in-your-splice-kits-dual-wall-heat-shrinkable-tubing

https://support.boshart.com/heat-shrink-splice-kit-installation-instructions-submersible-pump-cable

https://support.boshart.com/glossary-of-heat-shrink-tubing-terminology

TORQUE ARRESTOR

TORQUE ARRESTOR

- Installed directly above the pump on the riser pipe

- Keeps the submersible pump centered

- Prevents the pump from twisting in the riser pipe in the well casing

- Suitable for use in wells with 4” ID up through to 8” ID well casing

Boshart torque arrestors are installed directly above the pump on the riser pipe and are designed to keep the submersible pump centered and to prevent twisting in the well casing. Boshart offers two models: the standard TA48 and a heavier TA48D deluxe pattern. Both models can be used on 1" or 1-1/4" riser pipe and are adjustable for use in 4" up through 8" ID well casings. To install, clamp the bottom of the torque arrestor onto the pipe just above the pump. Slide the top down, expanding the rubber torque arrestor until it is equal to or slightly larger than the inside diameter of the well casing. Tighten the top clamp in place, and the torque arrestor is ready to keep your pump centered. The friction fit stops movement due to torque that could cause damage to your pump wire.

A special TA48-20 three-piece torque arrestor is available for 2" riser pipe applications.

ADDITIONAL RESOURCES

https://support.boshart.com/what-is-the-purpose-of-a-torque-arrestor

https://support.boshart.com/what-is-the-difference-between-a-standard-vs.-a-deluxe-torque-arrestor

https://support.boshart.com/do-you-have-a-torque-arrestor-for-1-1/2-drop-pipe

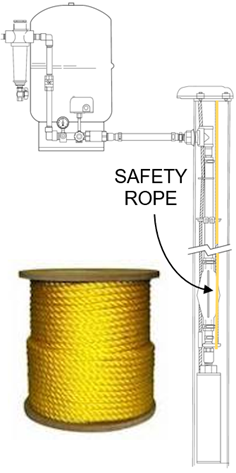

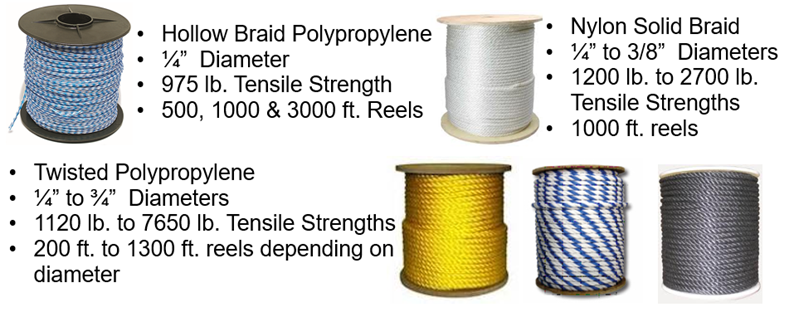

SAFTY ROPE

SAFTY ROPE

Safety rope is connected to the submersible pump and secured at the well head. Its function is to prevent pipe separation which would result in the pump being lost at the bottom of the well. It can also provide a backup means to enable the installer to pull the pump from the well casing if the riser pipe were to fail or a connection was to separate. Every pump should have safety rope secured to it before hanging it in the well.

Boshart offers rope diameters of ¼” through 3/4” diameters, with tensile strength ranging from 1120 lbs. up to 7650 lbs.

ADDITIONAL RESOURCES

https://support.boshart.com/does-polypropylene-safety-rope-have-anti-bacteria-properties

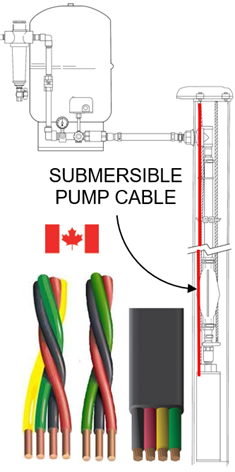

SUBMERSIBLE PUMP CABLE

SUBMERSIBLE PUMP CABLE

- Supplies power to the submersible pump

- BLACK-RED-GREEN (2 conductors plus a ground for 2 wire pumps)

- BLACK-RED-GREEN-YELLOW (3 conductors plus a ground for 3 wire pumps)

Boshart submersible pump cable is used to supply power to submersible pumps. It is manufactured to CSA Standard C22.2 No. 75-Thermoplastic Insulated Wires. The cable is available for both 2 and 3 wire pumps. Two wire pumps have the starting capacitor built into the submersible motor, and their installations use BLACK-RED-GREEN pump cable (2 conductors plus a ground). Three wire installations use BLACK-RED-YELLOW- GREEN pump cable (3 conductors plus a ground).

ADDITIONAL RESOURCES

https://support.boshart.com/what-is-wire-gauge

https://support.boshart.com/what-is-the-functional-difference-between-stranded-and-solid-core-wire

https://support.boshart.com/what-gauge-of-pump-cable-do-i-need

https://support.boshart.com/do-you-offer-pump-cable-with-a-reduced-ground-wire

https://support.boshart.com/what-the-heck-is-2-vs.-3-or-4-wire-pump-cable

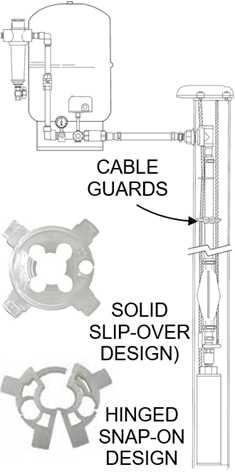

CABLE GUARDS

CABLE GUARDS

- Placed every 15 feet

- Centers the riser pipe to prevent damage to pump wires

- Solid design is installed over the end of the riser

- Self-clamping guards can be installed around the pipe

Cable guards are designed to keep the riser pipe centered in the well and to prevent damage to pump wires. If the pump cable is not properly secured and protected the insulation on the wires feeding the pump gets worn by rubbing against the inside of the well casing. Every time the pump, which hangs off the bottom end of 100 or 200 feet of the riser pipe, stops and starts, the whole installation moves in response to the torque of the motor. Boshart offers two types of cable guards. The first is a low-cost, solid design that must be installed over the end of the riser pipe. The second type is a self-clamping, hinged design that has a locking ratchet system that allows for the cable guard to be installed around the pipe.

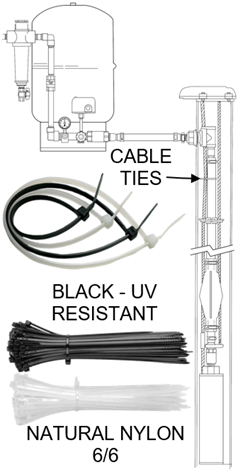

CABLE TIES

CABLE TIES

- Installed between the cable guards

- Secures the pump cable to the riser pipe

- Natural – less expensive and for indoor use

- Black – UV resistant and for indoor or outdoor use

Boshart cable ties are used to effectively secure the pump cable to the riser pipe between the cable guards. A good installation will have the pump cable against the riser pipe from the bottom to the top, free of loose or looped wire. Nylon cable ties are available in natural and black. Either can be used for a water well installation.

The natural nylon ties are less expensive but are not UV resistant, so they are not good for outdoor use. The black ties have carbon added to make them UV resistant, so they can be used in both indoor and outdoor applications.

Some codes require that the cable be fastened to the riser pipe at intervals of no greater than 10 ft. apart.

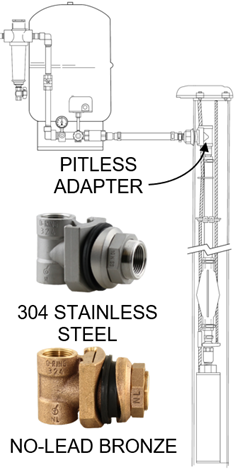

PITLESS ADAPTERS

PITLESS ADAPTERS

- Allows for easy connection of the riser pipe to the underground discharge piping below the frost line

- A watertight seal between the pitless slide and elbow is made by a compressing an O-ring

Pitless adapters allow for easy connection of the riser pipe from the submersible pump to the underground discharge piping which transfers the water to the house within the confined diameter of the well casing, below frost level. Slide type pitless adapters are the most common and widely used design. Boshart pitless adapters are a simple, reliable, and cost effective, 2-piece design that consists of two key components.

One half is called the pitless slide which is installed through a hole in the well casing below frost level. It is secured and sealed to the well casing by inner and outer gaskets and a compression washer and nut.

The other half is referred to as the pitless elbow which connects to the riser pipe coming up from the submersible pump. The elbow makes a 90 degree turn to discharge the water through the slide portion in the side of the well casing to the underground waterline. A watertight seal between the pitless slide and elbow is made by compressing an O-ring that is installed in a precision machined groove in the pitless elbow. It can slide freely in and out of the pitless slide as the assembly is lowered for installation or raised for pump removal.

ADDITIONAL RESOURCES

https://support.boshart.com/how-do-i-properly-install-my-pitless-adapter

https://support.boshart.com/what-is-the-working-pressure-for-slide-type-pitless-adapters

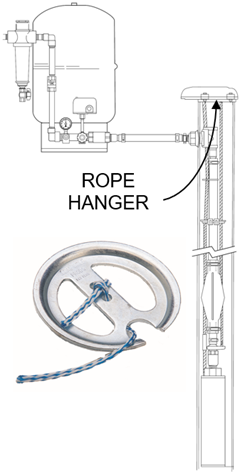

ROPE HANGERS

ROPE HANGERS

- Installed on the top of the well casing

- Easy method of attaching the safety rope securely to the well casing

The rope hanger is installed on the top of the well casing and does not rely on the structural strength of any other well component. This allows for the unobstructed installation of a well cap over the rope hanger onto the well casing. The rope hanger is easily removed from the well and set aside when the pump is being pulled from the well for service or replacement. Boshart rope hangers are designed to meet the need of well system installers looking for an easier method of attaching the safety rope securely to the well casing at the well head, rather than fastening the safety rope to other internal components.

Rope hangers are a unique item, invented by Mel Boshart, and are only available through Boshart Industries.

ADDITIONAL RESOURCES

https://support.boshart.com/rope-hanger-installation

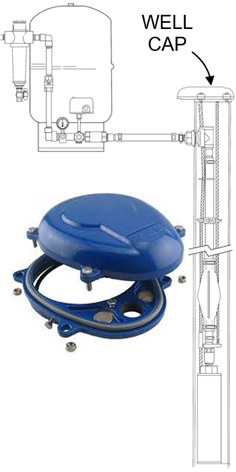

WELL CAPS

WELL CAPS

- Designed to go over the top of the well casing

- Prevent debris from entering the well and also ensure that bugs and small vermin cannot enter the well

- It is critical to know the exact well casing O.D. to determine the proper size well cap

Boshart well caps are designed to go over the top of a well casing. They provide a cover for the well to prevent debris from entering. They come in two basic types; a basic one-piece conduit cap, and in vermin proof, watertight & tamper-proof designs which are two- or three-pieces. Boshart recommends that at minimum a vermin proof design be used to ensure that bugs and small vermin cannot enter the well; most codes now mandate that a vermin proof cap with screened vents be used. When the conduit cap or the cover of a vermin proof well cap is removed, the installer has clear access to the well, allowing you to keep all your wiring attached. The bottom lower ring slides down over the well casing providing a watertight, vermin proof seal to the casing. This is achieved by compressing either a gasket or an O-ring between the casing and the lower ring. The lower ring is then secured into position by means of set screws. When ordering it is critical to know the outside diameter to determine the proper size well cap. To ensure you order the correct size well cap, you must measure across the top of the casing on the center line to determine the maximum distance across the top of the casing.

For more information, please refer to the ‘Pump & Well Accessories’ document that can be found in the additional training and reference materials.

ADDITIONAL RESOURCES

https://support.boshart.com/how-do-i-install-a-wtcc-series-well-cap

https://support.boshart.com/how-do-i-install-a-wtc-series-water-tight-well-cap

https://support.boshart.com/how-do-i-identify-a-well-cap-model-number-for-replacement-parts

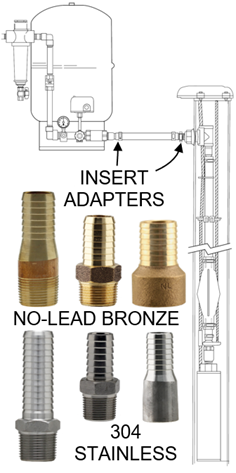

INSERT ADAPTER

INSERT ADAPTER

- Male thread on one end and an insert on the other

- Sharp barb profile ensures the insert will not pull out of the poly pipe

- Consistent, durable, heavy wall construction

- Special taper makes for easier installation

- Boshart offers unmatched quality insert fittings in a wide selection of materials

Boshart insert adapters have a male pipe thread on one end and an insert on the other. The BII adapters are specially designed with three key features that give them quality that is unmatched in the industry.

First, a sharp profile that bites into the poly pipe ensures that the insert will not pull out of the poly pipe without extreme force.

Second, the adapter is specially designed with consistent heavy wall construction for durability and longevity.

The third key feature is one that makes the installers job easier. The lead barb on each adapter is machined with a special taper to decrease the outside diameter of the first barb. This makes it easier to install the adapter into the poly pipe. Boshart maintains very tight control of the insert barb outside diameter with stricter tolerances than called for by the industry standard.

ADDITIONAL RESOURCES

https://support.boshart.com/what-type-of-poly-pipe-are-insert-fittings-designed-to-work-with

https://support.boshart.com/pressure-temperature-ratings-for-bronze-insert-fittings

https://support.boshart.com/pressure-temperature-ratings-for-304-stainless-steel-insert-fittings

https://support.boshart.com/insert-fitting-pull-off-resistance-testing

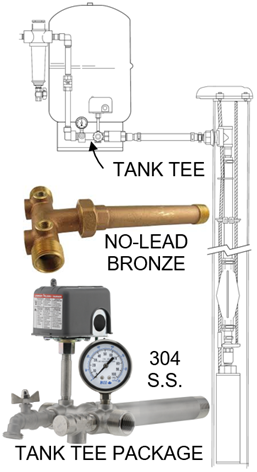

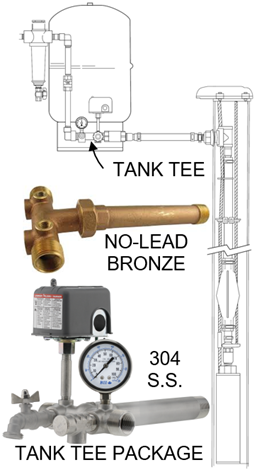

TANK TEES

TANK TEES

- Multi-port fitting designed to connect a tank to the water system

- Faster installation due to fewer threaded connections

- Available in a variety of materials and styles

- Available in union and non-union designs

Boshart tank tees are simply a multi-port fitting designed to connect a tank to a water system. The multi-port feature allows one fitting to do the same job as 8 or more pipe fittings, making it compact and helps to avoid potential leaks. Tank tees come in a variety of materials, styles, and lengths to accommodate any tank on the market. The tank tee is installed by threading it to the discharge of the pressure tank. Special quick connect union designs are available for some brands of tanks. There is only one pipe connection on this tank. When the tank is connected the tee has a total of three main connections and four additional accessory ports. The connection on the leg goes to the tank, while one of the lateral connections goes to the pump. The other goes to the household plumbing system. Union tees provide a quick means to replace a defective water tank without having to disassemble multiple connections.

ADDITIONAL RESOURCES

https://support.boshart.com/what-should-i-consider-when-selecting-a-tank-tee

https://support.boshart.com/07st-series-stainless-steel-union-tank-tee-installation

https://support.boshart.com/wellmate-wm-series-quick-connect-tank-tee-installation-instructions

PRESSURE SWITCHES

PRESSURE SWITCHES

- Reacts to the water system pressure to start and stop the submersible pump

- Low-pressure cut-off models protect the pump

- Specialized pressure switches can be wired (in series) to provide protection from high and low water pressure

A pressure switch controls the submersible pumps operation. It has a built-in diaphragm that moves back and forth reacting to the water system pressure. When pressure decreases, the diaphragm retracts, and the spring-loaded contacts will trip causing the contact to snap to the closed position. This is referred to as the cut-in and starts the pump.

As the submersible pump builds the system pressure the diaphragm is forced forward, forcing the contact mechanism to trip again and the contacts snap to the open position. This is referred to as the cut-out and stops the pump. By using a low-pressure cut-off switch which is designed to turn off the pump in the event of a low-pressure condition, this feature is designed to protect submersible pumps from running dry if the water level in the well drops below the intake screen of the pump due to drought conditions.

Boshart offers specialized pressure switches that can be wired in series in addition to the standard pressure switches to provide protection.

ADDITIONAL RESOURCES

https://support.boshart.com/what-information-is-needed-to-properly-select-a-pressure-switch

https://support.boshart.com/what-is-meant-by-cut-in-and-cut-out-settings

https://support.boshart.com/what-are-the-adjustment-ranges-for-a-ps02-series-pressure-switch

https://support.boshart.com/how-do-i-adjust-a-pressure-switch

https://support.boshart.com/is-the-low-pressure-cut-off-setting-on-a-pressure-switch-adjustable

https://support.boshart.com/is-the-low-pressure-cut-off-setting-on-a-pressure-switch-adjustable

https://support.boshart.com/wiring-a-pressure-switch

https://support.boshart.com/what-is-pressure-switch-differential

https://support.boshart.com/pressure-switch-wont-turn-on

https://support.boshart.com/why-is-my-low-pressure-cut-out-switch-nuisance-tripping

https://support.boshart.com/i-have-totally-messed-up-my-pressure-switch-settings-now-what

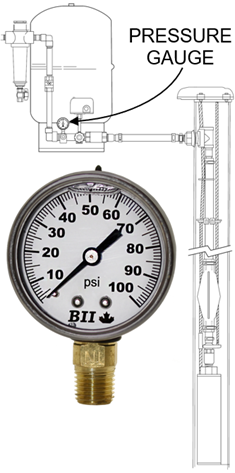

PRESSURE GAUGES

PRESSURE GAUGES

- Easy monitoring of system pressure

- Many configurations and quality grades

- Dry or liquid filled

- Boshart 2” is the most common

- Most accurate and lasts longer when operating in mid-range

The pressure gauge allows the installer and homeowner to easily monitor what the pressure system is doing, and to verify the cut-in and cut-out pressure settings of the pressure switch. Boshart gauges are available in many configurations and quality grades, dry or liquid filled. Most commonly used is a 2” dial steel case gauge with a ¼” lower mount connection. It is installed in one of the two upward facing accessory ports on the tank tee head.

When ordering a pressure gauge the pressure range should be selected to ensure that the gauge will operate in the middle 1/3 of the dial face pressure range. Pressure system gauges are most accurate and will last significantly longer when they operate in the middle of the pressure range.

ADDITIONAL RESOURCES

https://support.boshart.com/pressure-gauge-range-selection

https://support.boshart.com/what-are-the-advantages-of-installing-a-liquid-filled-gauge

https://support.boshart.com/how-do-i-vent-a-liquid-filled-gauge

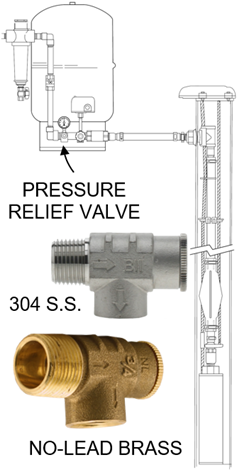

PRESSURE RELIEF VALVES

PRESSURE RELIEF VALVES

- Provides protection from excessive pressure

- Max 100 psi pressure relief setting recommended to protect tank and plumbing from damage

- Available in various materials

Boshart relief valves provide the plumbing system with protection from excessive pressure. Excessive pressures could result in catastrophic failure of plumping pipes and components in the in-house plumbing, potentially resulting in water damage. The relief valve is a spring-loaded valve that will open only if the system pressure exceeds the pre-set blow-off setting of the relief valve. This eliminates the possibility of the system building pressures beyond that setting ensuring that the plumbing system is not subjected to extreme pressures. It is important that a relief valve be properly plumbed to a suitable drain that can handle the discharged water flow to ensure that there is no property damage due to flooding in the event the relief valve does blow off releasing water. Drain valves are available in various materials.

ADDITIONAL RESOURCES

https://support.boshart.com/are-relief-valves-suitable-for-hot-water-applications

https://support.boshart.com/how-do-i-adjust-a-relief-valve

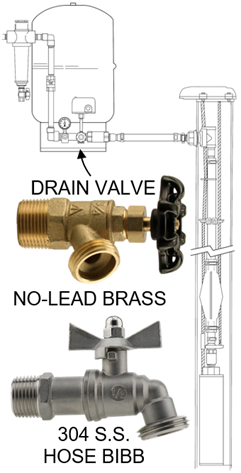

DRAIN VALVES

DRAIN VALVES

- Also known as sediment faucets and boiler drain valves

- Allows collection of water samples

- Allows you to acquire water from the system

- Provides a means to drain the tank

- Many styles, configurations, and materials to match tank tee construction

- 3/4" garden hose connection carries water being drained away from the area

A drain valve, also known as a sediment faucet and boiler drain valve, is installed in the second outward facing accessory port. This drain valve has multiple functions. It works to take water samples, acquire water from the system, and to provide a means to drain the tank and water system if a pressure tank must be replaced.

Boshart drain valves are available in many styles and configurations and in various materials to match the tank tee construction. Normally all drain valves are supplied with a standard ¾” garden hose connection on the outlet. However, in some areas plumbing code does not allow a threaded outlet and a sampling faucet must be used. A sampling faucet is similar but does not have the garden hose connection.

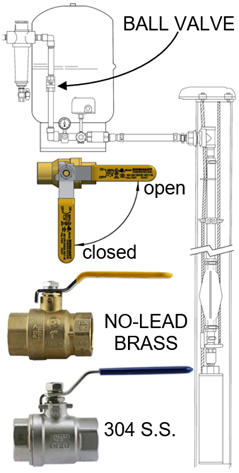

BALL VALVES

BALL VALVES

- Provides a means to shut off the water supply to the house

- Allows the installer to isolate the water system from the in-house plumbing system

- Bronze and stainless steel available

A Boshart ball valve should be installed on the discharge side of the pressure tank to provide a means of isolating the plumbing system from the water well pressure system. This provides a means to shut off the water supply to the house in the event of a component failure in the in-house plumbing system and enables the installer to isolate the water system and prevent the entire in-house plumbing system to drain back when the water system requires repairs.

ADDITIONAL RESOURCES

https://support.boshart.com/how-do-i-properly-install-a-threaded-ball-valve

https://support.boshart.com/how-do-i-install-a-solder-ball-valve

https://support.boshart.com/do-the-terms-schedule-40-and-schedule-80-apply-to-pvc-ball-valves

![]()

Boshart offers a wide selection of accessory products that are required during the installation process. These can be added to an order for water system components for a convenient one-stop resource for all installation needs.

PIPE FITTINGS AND NIPPLES

Pipe nipples are ready cut pipe in black and galvanized steel, and bronze. They are also available in brass, 304 and 316 grade stainless steels, and PVC.

Pipe fittings are available in malleable iron, bronze, 304 and 316 grade stainless steels, and schedule 40 & 80 PVC.

https://support.boshart.com/making-npt-connections

https://support.boshart.com/making-a-leak-proof-stainless-steel-threaded-connection

THREAD SEALANTS

THREAD SEALANTS

To make a watertight seal we offer both thread sealant paste and a wide selection of P.T.F.E. thread sealing tapes in various grades. Other grades are available which are specially designed for specific materials such as stainless steel.

https://support.boshart.com/what-is-ptfe

https://support.boshart.com/how-to-apply-ptfe-thread-seal-tape

https://support.boshart.com/gray-magic-applications

https://support.boshart.com/is-gray-magic-thread-sealant-considered-to-be-food-grade

https://support.boshart.com/what-is-the-drying-or-cure-time-for-gray-magic-thread-sealing-compound

PIPE WRAP TAPE

PIPE WRAP TAPE

For installations using galvanized riser pipe Boshart offers pipe wrap tape which provides a barrier between the pipe and the aggressive water to eliminate the corrosion of the pipe adding years the life of the system.

ELECTRICAL TAPE

ELECTRICAL TAPE

All weather and cold weather electrical tapes and self bonding tapes are also great add-on items to every order.

FLOW CONTROLS

FLOW CONTROLS

https://support.boshart.com/flo-trol-model-cd900-constant-flow-control-valve-operation

WATER FILTERS

https://support.boshart.com/what-do-we-mean-by-filtration

https://support.boshart.com/how-does-filtration-work

https://support.boshart.com/what-are-the-required-steps-to-properly-select-a-water-filter

https://support.boshart.com/what-mesh-rating-do-i-need-for-my-spin-out-filter-or-separator-filter

https://support.boshart.com/my-sediment-filter-plugs-up-with-sand-and-silt-very-quickly

https://support.boshart.com/cleaning-your-spin-out-filter

RECAP

Now that you have completed this article you can identify all the components in a typical well installation. You have a solid understanding of the products and their purpose, where the components are located, and how they work together in your well system. You will now be able to select the right products to put together a high quality, durable well water system.

ADDITIONAL RESOURCES

For additional product information, including technical support, detailed installation instructions, brochures, product guides, and warranty information, please call or email our customer service department between 8 am and 5 pm, Eastern Time, Monday through Friday.

You can also refer to our website at www.boshart.com.

Technical support: https://support.boshart.com/

Technical support: https://support.boshart.com/ Installation Instructions: https://boshart.com/literature/technical-sheets/

Installation Instructions: https://boshart.com/literature/technical-sheets/- Brochures: https://boshart.com/literature/brochures-sellsheets/

CUSTOMER SERVICE

1-800-561-3164 TEL: 519-595-4444 FAX: 519-595-4380

MANY PRODUCTS…ONE SOURCE