How do I select a Heat Shrink Splice Kit?

How do I select a Heat Shrink Splice Kit?

There are a number of things to take into account when selecting a heat shrink splice kits. The following article will provide direction on several topics that you may or may not be aware of. You may also find the link below helpful:

https://support.boshart.com/glossary-of-heat-shrink-tubing-terminology

Black vs. Clear

Black tubing is flame retardant and should be used to make splices in all above ground electrical cable splicing applications.

Due to the removal of the carbon content (carbon black) to produce transparent tubing, the clear tubing is not flame retardant. Clear heat shrink tubing is commonly used in making power cable splices to submersible water pump motors. This is because it allows the installer to visually see the flow of the adhesive while shrinking the tube to make sure there is no air pockets which could jeopardize the watertight seal. Also, flame retardancy is non-issue since the splice is always under water. They are also used for over-sleeving identification markers on various products.

Wire Size / Insulation O.D.

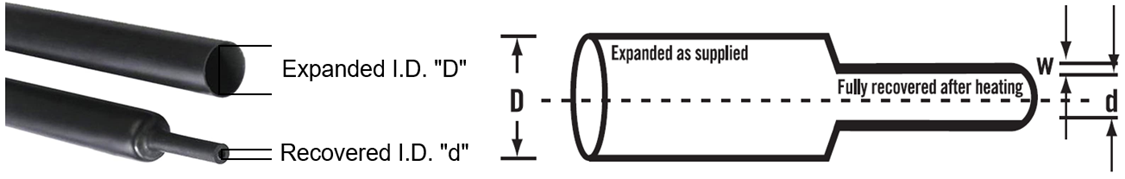

Choosing the right heat shrinkable tubing size is all about taking two key dimensions into consideration, including both the Expanded I.D. and the Recovered I.D.

Largest Diameter – Determine and largest section on the parts you will be covering with the tubing, use a caliper or a ruler to measure the diameter. Choose heat shrinkable tubing that has an “expanded” inside diameter (I.D.) that is 20% to 30% bigger than your largest measurement. The extra twenty to thirty percent will allow room to slide the expanded tubing over the largest part.

Largest Diameter – Determine and largest section on the parts you will be covering with the tubing, use a caliper or a ruler to measure the diameter. Choose heat shrinkable tubing that has an “expanded” inside diameter (I.D.) that is 20% to 30% bigger than your largest measurement. The extra twenty to thirty percent will allow room to slide the expanded tubing over the largest part.

Smallest Diameter - The smallest diameter is of equal or even higher importance! Check to make sure that the heat shrinkable tubing has a high enough shrink ratio to get a snug fit (recovered I.D.) on the smallest part you wish to cover.

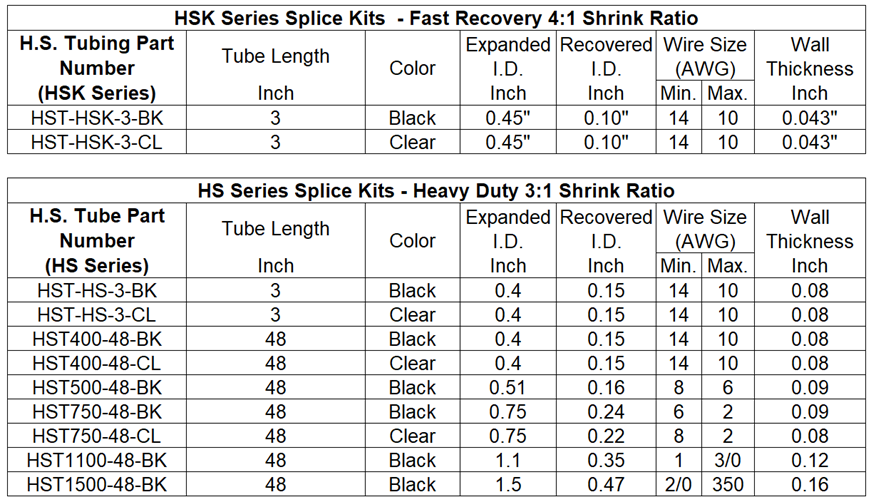

NOTE: You may have to use the 4:1 shrink ratio tubing in some applications where the motor leads have very thin insulation such as cross linked or teflon.

Number of Tubes = Number of Conductors plus Ground Wire

The kits will show the total number of heat shrink tubes, these are for both the conductors and the ground wire. For a 2-wire pump you will require three heat shrink tubes and connectors, for 3 wire pumps you will require four heat shrink tubes and stakon connectors. You will notice that for some splice kits the number or the size of stakon connectors may differ due to the ground wire which may be smaller for the reduced ground and in other kits there maybe one extra stakon connector than the number of tubes.

3:1 vs. 4:1 Shrink Ratio.

The HEAVY DUTY 3:1 RATIO HEAT SHRINK KITS

3:1 - This heat shrink tubing will be one-third of its original size once the heat is applied. The original heat shrinkable tubing is three times larger than its shrunken form.

PROS - They have greater material mass which provides a thicker wall for added abrasion protection.

CONS – They take more heat and time to bring the increased material to “shrink” temperature. This results in them appearing to be difficult to shrink down to the recovered ID when in cold, windy conditions.

The FAST RECOVERY 4:1 RATIO HEAT SHRINK KITS

4:1 - This heat shrink tubing will be one-quarter of its original size once the heat is applied. The original heat shrinkable tubing is four times larger than its shrunken form.

PROS - They shrink down to recovered ID very quickly, appearing to take less heat and time. This is due to decreased material and thinner wall thickness resulting in less time to bring them up to the “shrink” temperature. This results in them appearing to be easier to shrink down to the recovered ID when in cold, windy conditions.

CONS – They have less material mass which provides a thinner wall and less abrasion protection.

NOTE: For the most part the type of heat shrink contractors choose to work with is a matter of personal preference, there is no right or wrong when it comes to which type of kit you choose. Many installers choose the fast recovery kits to make a watertight seal, and then add a few layers of electrical tape over the splices to add abrasion resistance. This is a practice that is used on the heavy duty as well if the splices may be subjected to a lot of abrasion on a deep pump set or sharp edges in a rock formation.

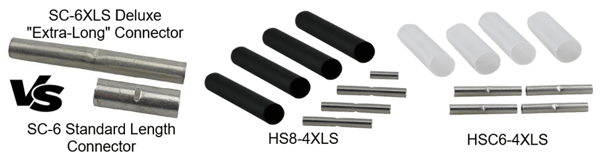

Standard vs. Deluxe Splice Kits for Wire Sizes #8, #6 & #4 AWG

Boshart's deluxe, heavy-duty heat shrink kit series use the same heat shrink tubing as the heavy-duty heat shrink kits. However, the tubes are 6” long rather than the standard 4”. They also have extra-long stakons (butt conn) for double crimping. They are RoHS Certified according to directive 2002/95/EC <0.1% Pb.

The extra tubing length provides additional sealing area for the adhesive. Some installers opt to purchase heat shrink in 48” lengths and cut it to the desired length. A little extra length is great because heat shrink tubing also shrinks lengthwise. This reduction in the overall length measurement is referred to as " longitudinal shrinkage" which in not typically on the tubing specification but is common for most heat shrinkable tubing products.

Additional Resources:

https://support.boshart.com/can-heat-shrink-splice-kits-be-used-in-underground-applications