What type of poly pipe are insert fittings designed to work with?

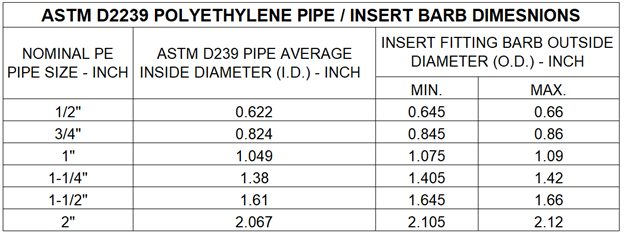

Insert fittings which are designed for polyethylene (PE) plastic pipe manufactured to the ASTM-D2239 standard, are designed to work with PE pipe with inside diameters shown in the chart below.

They are typically used with 50 PSI utility pipe, 75 and 100 PSI pipe, and any other PE pipe which is inside diameter (I.D.) controlled to these dimensions. You may see PE pipe rated to 160 & 200 PSI. We recommend the use of pipe certified to CSA B137.1 for potable water systems.

Insert fitting barbs designed for PE pipe are purposely manufactured to a larger diameter as per the above chart. Due the ridged structure of PE pipe, the rigidity of the pipe does not allow a worm gear type clamp to compress the pipe beyond its original diameter. For this reason, the fittings are designed to force the expansion or stretching of the PE pipe when the fitting is inserted. Due to the memory of the pipe it tries to return to its original manufactured diameter like an elastic band. When tightening the gear clamp this memory assists the clamp in forming the poly into the barb profiles and makes a positive seal with excellent pull off resistance.

INSTALLATION TIPS:

#1 - In cold weather it may be very difficult to insert an insert fitting into PE pipe. Heating the pipe by immersing the end in hot water will make the pipe more pliable, easier to insert, and easier to properly form the plastic to take on the form of the insert barbs. If using a heat gun or torch extreme caution must be exercised to ensure you do not damage or degrade the pipe.

#2 – When installing a submersible pump on PE pipe, it is recommended to use an extra long insert fitting with additional barbs (serrations) allowing for double clamping for maximum pull-off resistance.

CAUTION:

#1 - These insert fittings ARE NOT meant to be used with PE pipe manufactured to standards which are O.D. (outside diameter) controlled. You may also find some 160 PSI PE pipe manufactured to copper tubing size (C.T.S.) with inside diameters that that differ from the above values.

#2 - Do not confuse insert fittings with hose fittings. The use of a hose fitting, which are manufactured with smaller barb diameters than poly (PE) pipe, will result in a leaking connection with very little or no pull off resistance!