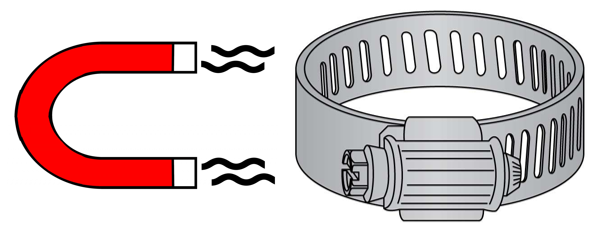

My all 300 Grade stainless gear clamp has magnetism, is it stainless steel?

It is actually a myth that stainless steel is not magnetic and that if it is magnetic, it is poorer quality or subject to increased corrosion rates.

Testing has proven this is not so. Type 300 stainless steels (referred to austenitic grades) are confusingly referred to “non-magnetic” alloys as in their raw material form, they are non-magnetic. However, when this material is worked, bent, deep drawn, or formed into tube or pipe it can become magnetic. Even when it is cut, the deformation in the edge of the metal can cause magnetism. Magnetism is not a negative characteristic. In fact, the rise in magnetism is directly related to an increase in tensile strength and work hardening caused by the heat and friction of cold forming. It does not reduce the corrosion resistance or cause any molecular change in the austenitic raw material. The strength of the magnetism depends on how much the metal has been deformed. Corrosion resistance depends entirely on the percentage of chromium, nickel, and (sometimes) molybdenum that is in the stainless steel. Higher contents of chromium, nickel, and molybdenum result in increased corrosion resistance (eg. Type 316 SS).

The bottom line is that the magnetic testing can be very misleading and should be avoided!

For a true evaluation of alloy quality and corrosion resistance of stainless steel, one must analyze the alloy composition and verify the percentages of chromium, nickel, & in some alloys molybdenum!

The BOSHART Commitment: We will continue to verify the quality of our stainless steel products by testing the percentages of chromium, nickel, and molybdenum by working with a metallurgist or by using of a trustworthy method.

The BOSHART Commitment: We will continue to verify the quality of our stainless steel products by testing the percentages of chromium, nickel, and molybdenum by working with a metallurgist or by using of a trustworthy method.