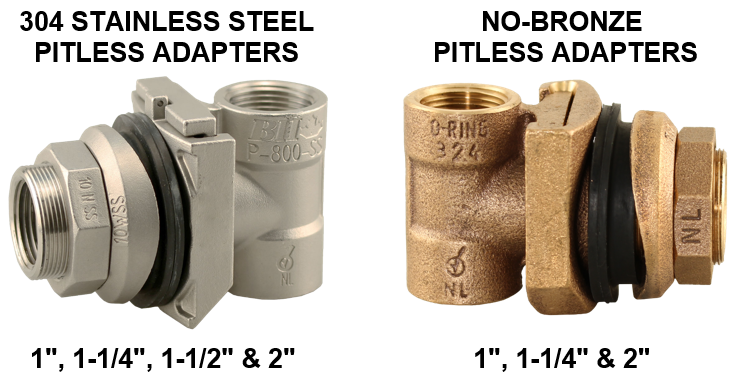

How do I properly install my Pitless Adapter?

There are 6 basic steps to follow to properly install a single pipe, slide type Pitless Adapter for submersible pump applications.

Single pipe, slide type Pitless Adapters are the most common type and they are mainly used for submersible pump installations. They can also be used for shallow well jet pump systems where a single suction line is lowered into the well with a foot valve attached. A shallow well jet system is limited to a 25 foot deep well or 30 feet if there is ideal conditions at sea level.

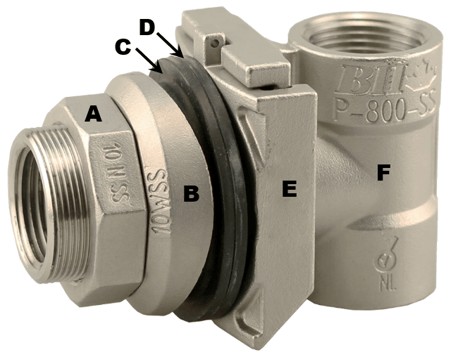

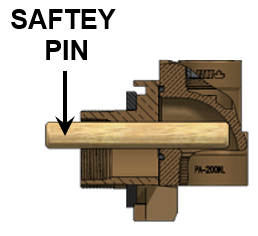

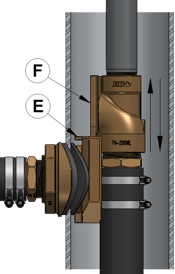

The picture below shows all of the components of a single pipe Pitless Adapter.

A - Compression Nut, B - Compression Washer, C- Outer Rubber Seal (Gasket), D- Inner Rubber Seal (Gasket), E - Pitless Slide, F - Pitless Elbow

Step 1:

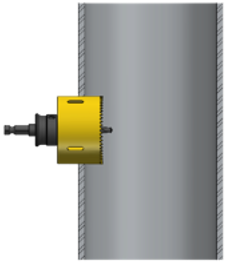

First, start off by determining the desired location to cut the hole in the well casing. Make sure it is aligned with the trench for the service line and that it is at the proper bury depth to ensure the service line won't freeze.

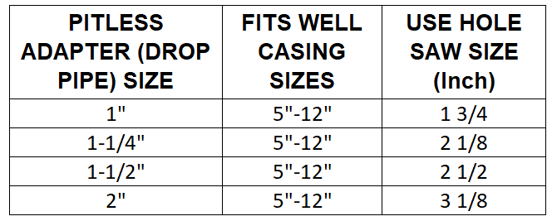

Using the appropriate hole saw size as per the chart below, cut the hole through the well casing and remove the burrs.

Do not use a cutting torch to cut the hole in the side wall of the well casing!

Step 2:

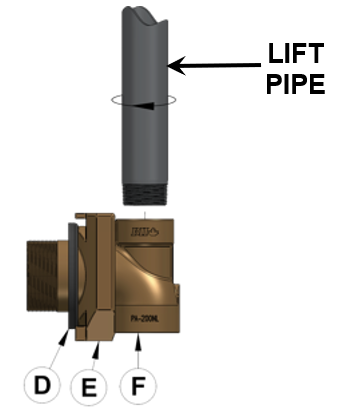

Next, you will need to remove the brass nut "A", the brass washer "B", and the outside rubber washer "C".

Safety Tip: To prevent separation of the slide Pitless from the elbow during installation, simply insert a short piece of wooden dowel or plastic pipe in the Pitless discharge and into the elbow. The wood or plastic pipe will act as a safety pin. The safety pin secures the slide to the elbow and pull pipe assembly eliminating the risk of accidentally dropping the slide Pitless down the well.

Caution: In order to ensure that it is impossible to make the service line connection without removing the safety pin, the safety pin should stick out a minimum of 1/4" from the Pitless discharge connection. Also, be sure it is a sufficient diameter.

Step 3:

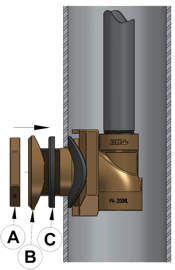

Once "A", "B", and "C" have been removed, you will need to thread a portion of steel pipe (lift pipe or pull pipe) into the top of the Pitless elbow "F". Then lower it inside the well casing, carefully inserting the slide through the pre-cut hole. Make sure that the rubber washer "D" is making direct contact with the inside of the well casing.

Step 4:

Next, you will need to install the outer rubber washer "C", brass washer "B", and the brass nut "A" from outside of the well casing. You will need to hand tighten the nut ensuring the washer contour is aligned with the casing profile.

Then, tighten the brass nut using a wrench until the gaskets are visibly compressed. It's important to ensure the Pitless adapter remains upright by holding onto the pull pipe straight in the well casing.

Step 5:

Remove the safety pin to allow the elbow "F" to be pulled out of the slide "E" and up out of the well casing. At this point, you can attach the pipe column (drop pipe and submersible pipe) and install the pump by lowering the pump column back down the well, seating the Pitless elbow back into the slide of the Pitless adapter. Make sure you firmly position it into the slide before disconnecting from the pull pipe.

Step 6:

Once you have checked that it is firmly positioned, you can install the discharge pipe (service line).

Step 7:

Once it has been installed, ensure you check for leaks prior to back filling the trench.