Can sediment filters be installed between the pump and pressure tank?

Can sediment filters be installed between the pump and pressure tank?

Can sediment filters be installed between the pump and pressure tank?

No!

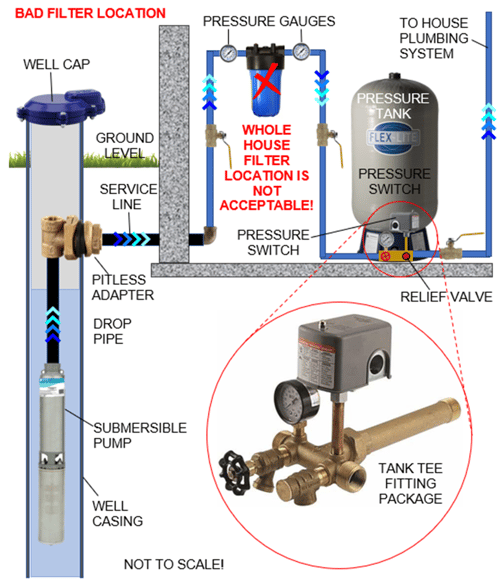

Installation of a sediment filter between the submersible pump and the pressure tank must be avoided. The reason for this is because as the filter cartridge loads with sediment, as it is intended to do, it eventually gets clogged up. This could result in damage to the pump and filter.

The problem occurs when the pressure in the water tank drops below the cut-in (pump start) setting of the pressure switch. The switch will trip, starting the well pump. The pump will then be pumping water against a clogged filter cartridge building excessive pressure. However, the pressure switch will not be able to read this because it would be located after the filter and will not be able to tell the pump to cut-out (shut off). The pump will continue to run, building pressure to the maximum pressure the pump is capable of producing. Since the pressure relief valve is installed in the tank tee, the excessive pressure is not released. Constant running of the pump at full pressure will eventually destroy the pump and possibly damage the filter due to over pressure.

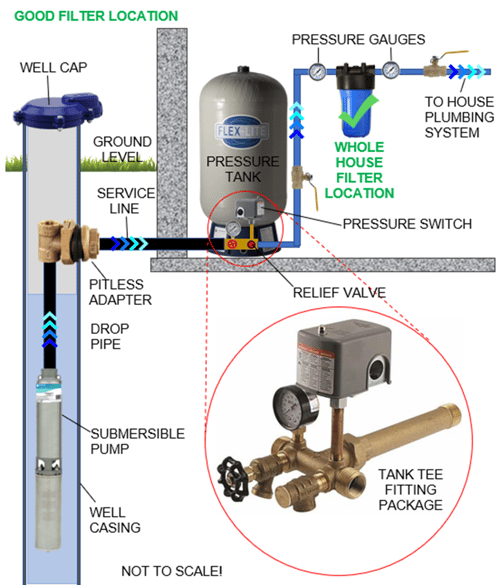

Therefore, sediment filters should always be installed AFTER the pressure tank.

Where are whole house water filter housings typically installed?

Whole house filters are installed on the main water pipe in the house, after the pressure tank when pumping from a well or lake, or after the water meter for homes supplied with municipally treated water.

Additional Resources / Articles of Interest:

https://support.boshart.com/what-are-the-required-steps-to-properly-select-a-water-filter

https://support.boshart.com/how-to-replace-a-whole-house-water-filter-cartridge