Why do clamps with a 1/2” wide band preform or seal better than clamps with a 9/16” wide band?

Unfortunately, there is a great deal of misleading information on this topic. In this article we will explain using facts why 9/16” wide band clamps, when torqued equally at 60-inch lbs., provide less sealing pressure onto insert fitting barbs than clamps with ½” wide bands.

We will also address three misleading claims made by Ideal. The claims are…

#1 – Wider Band, Greater Strength – This claim that a wider band has increased material content and therefore provides greater strength SHOULD be true in theory.

FACT: The benefit of more raw material was lost due to poor design. See a deep dive into “The WEAKEST Link” information at the end of this article.

#2 – Prevents Cold Flow Leakage - It is true that the wider 9/16” band covers a 12.5% more sealing surface.

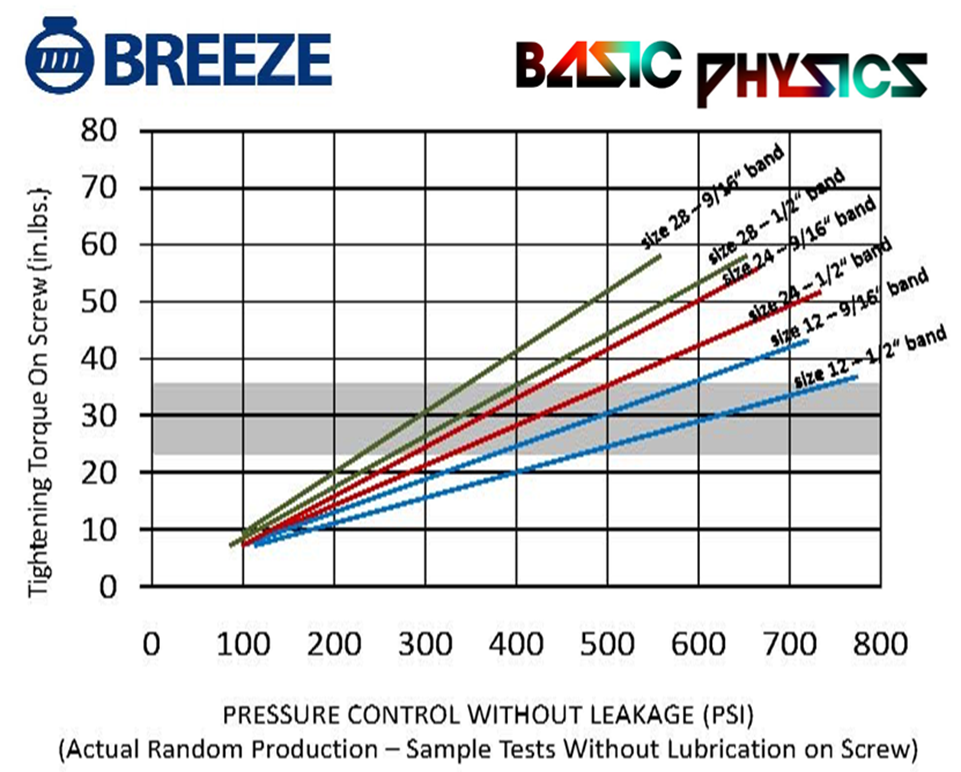

FACT: Covering more surface area has a negative effect on the sealing force or pressure applied to the insert fitting barbs (serrations). When the same 60-inch lbs. assembly torque is applied to the worm screw, the same force is then applied to the larger surface area of the wider band. Spreading out the force over a larger footprint reduces the actual pounds per square of clamping force. See the Pressure Control Without Leakage (PSI) Chart published by Breeze below.

You can see that at any given equal installation torque, a narrower band (1/2”) develops higher sealing pressure than a wider (9/16”) band because sealing force is exerted and transferred over 12% smaller surface area resulting in a higher pounds per square inch.

The snowshoe analogy may be an effective means to help explain and remember this basic principle. Simply put - the smaller surface area of a boot alone applies greater pressure on the snow surface causing you to break through the surface. The snowshoe increases the surface area allowing one to walk on the surface, while the body mass remains constant.

#3 – Reduces Blow-Apart – It is true that a wider band footprint over the hose enables the clamp to catch more of the insert fitting barbed surface.

FACT: Either ½” or 9/16” wide bands will apply pressure to 2-3 barbs depending on their positioning. The reduced clamping pressure applied will offset any of this wider footprint. In fact, the blow off resistance increases when the clamp can fully compress the poly pipe deeply into the serrations.

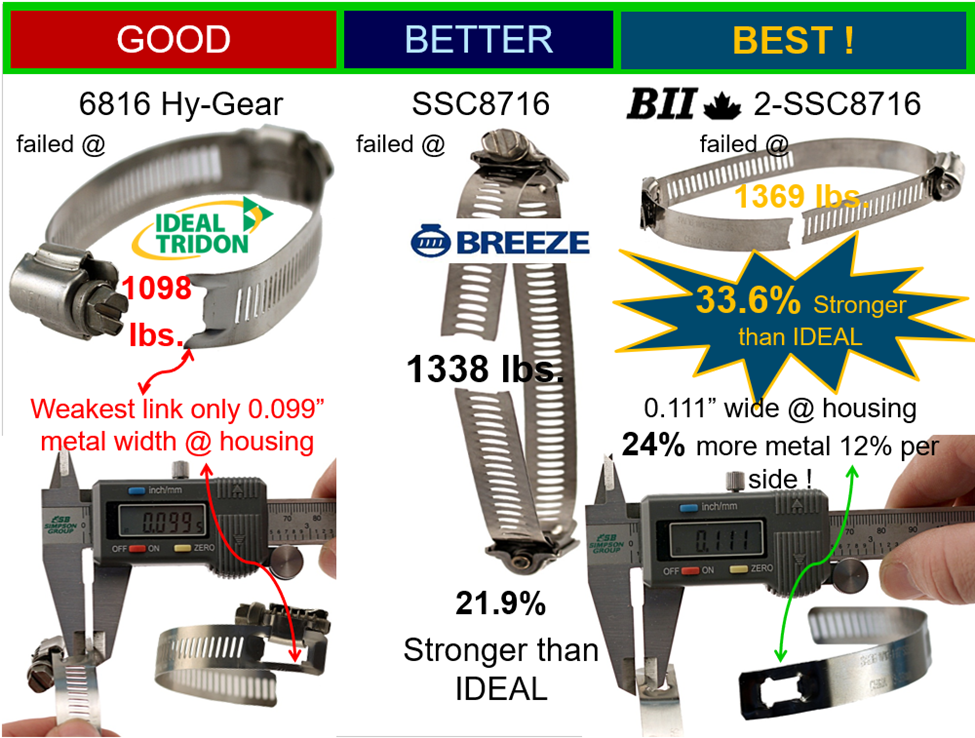

Time and time again we have heard the claims that the IDEAL 9/16” band clamps are stronger. This has been a wide-spread misconception in the industry; however, we have never seen any factual data of testing to back up this claim. In theory this claim seems more than reasonable from a quick visual inspection.

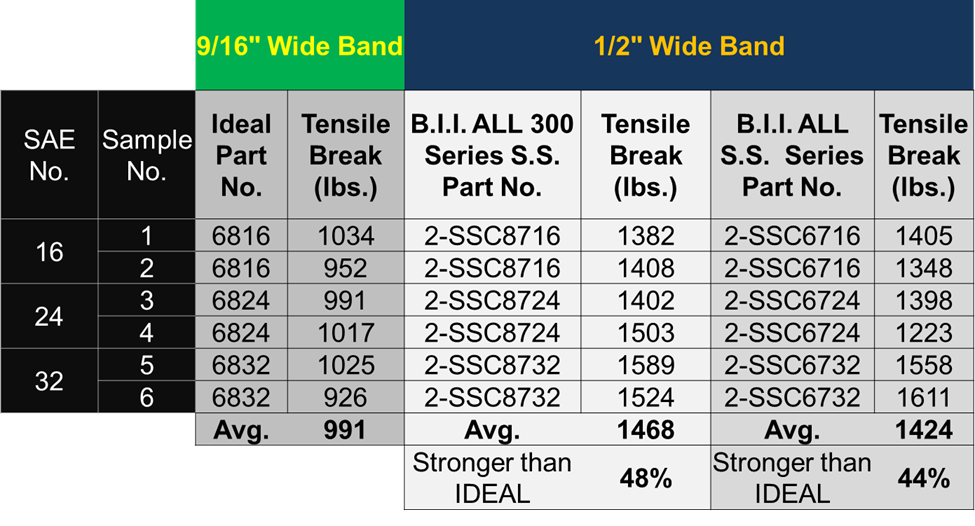

Boshart decided we wanted information on just how much stronger the 9/16” bands actually were. We expected to confirm that the 9/16” band would be significantly stronger in tensile strength, so we put them all to the test. Much to our surprise, the Ideal clamp was not significantly stronger as we expected from the claims. The 9/16” band actually failed at the lowest force of the three brands tested.

Since the result was so unexpected, it was clear that a deeper evaluation of the clamp was required to determine why a wider 9/16” band was not as strong as the 1/2” wide band. We found that the Ideal 9/16” band has “The Weakest Link”. The weak spot has only 0.099” of metal width per side due to poor band design. This weak spot cannot be seen unless the clamp is disassembled. The 9/16” bands fail (snaps) at the cut out for the interlocking housing connection at lower forces than either the BII 2-SSC8716 or the BREEZE SSC8716 clamp. The BII clamps have 0.111” of metal width, 12% per side resulting in a 24% increase in metal connection in the band at the housing connection. The photos below provide a visual as to the location of this major design difference.

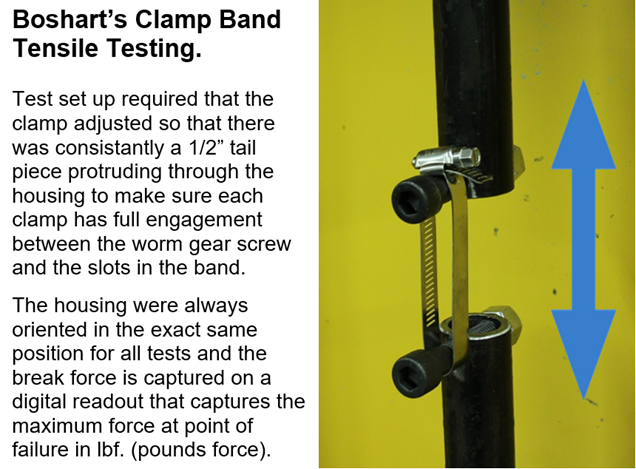

Boshart’s Clamp Band Tensile Testing:

To ensure accuracy and further validate the test results, we tested 18 more clamps to verify the results were similar. Surprisingly, the first Ideal #6816 Hy-Gear produced the best result and the BII clamp had two that failed at slightly lower tensile force. However, the average result from the overall testing proved the BII clamp to out-perform the original two test results. On the larger sampling the average BII clamp was 46% stronger, therefore the percentages in the chart below are on the conservative side!