Can I use an acetylene torch to cut the hole for a Pitless Adapter in the side wall of the well casing?

Let’s start by saying just because you can, does not mean you should! The answer to this question is both YES and NO! It depends on the type of Pitless Adapter that is being installed. Below we have detailed when and where a cutting torch can and cannot be used to install a Pitless.

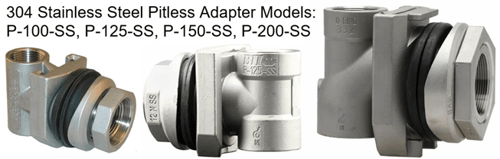

SLIDE TYPE PITLESS ADAPTERS - Boshart advises the answer is a strong no!

Unfortunately, if you look up information on the internet you will find several articles that advise to install or attach the Pitless Adapter to the sidewall of the well casing, you start by cutting a hole with an acetylene torch. Boshart does not endorse the use of a cutting torch!

Two reasons you should not use a cutting torch to install a slide type Pitless Adapter:

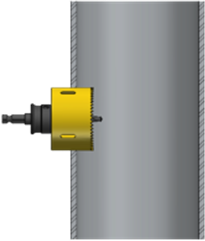

#1 - Cutting a hole with a torch takes great skill to get it perfect and free of any cutting slag especially on the inside of the casing. It is impossible to cut a perfect hole free of cutting slag using a torch. The use of a hole saw provides a good fit which is extremely important to obtain a 100% watertight and sanitary seal on both the inside and outside of the casing with the gaskets. This seal is crucial to ensure that your drinking water supply is protected from surface water contamination. Failure to use a hole saw and follow proper installation instructions could result in well contamination which is the sole the responsibility of the installer.

#1 - Cutting a hole with a torch takes great skill to get it perfect and free of any cutting slag especially on the inside of the casing. It is impossible to cut a perfect hole free of cutting slag using a torch. The use of a hole saw provides a good fit which is extremely important to obtain a 100% watertight and sanitary seal on both the inside and outside of the casing with the gaskets. This seal is crucial to ensure that your drinking water supply is protected from surface water contamination. Failure to use a hole saw and follow proper installation instructions could result in well contamination which is the sole the responsibility of the installer.

Use the link below for Pitless Adapter installation instructions:

https://support.boshart.com/how-do-i-properly-install-my-pitless-adapter

#2 – The use of a cutting torch is not permitted in some jurisdictions. Some well construction regulations make statements along these lines, “The person constructing the well must not use a cutting torch to make an opening in the casing wall when installing a Pitless adapter. Typically, a properly sized hole saw, as outlined in the manufacturer’s specifications, is used to drill out an opening in the casing.”

Warning: Always install Pitless Adapters in full compliance with all applicable water well construction, building, and plumbing codes in your area!

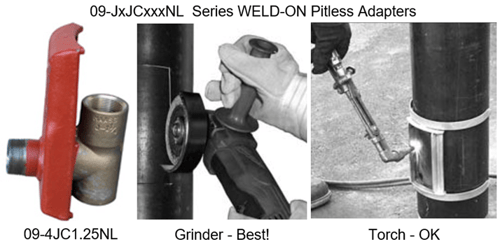

WELD-ON TYPE PITLESS ADAPTERS – Yes!

If you are installing a weld-on type Pitless Adapter you cannot use a hole saw, but you will have two alternatives to cut the large, rectangular hole through the side wall of the casing. The use of a grinder is the best option, however the manufacturer does allow the use of a torch.

Cutting a “clean” hole with a torch takes great skill. A larger hole allows the installer to clean up the cut to make sure it is free of cutting slag or burrs before making the weld. Since the Pitless is welded to the casing to provide a watertight and sanitary seal, there is less concern with regards to having a perfectly smooth surface required to seal gaskets. The hole should be cut by an experienced and qualified well contractor, following the manufacturers installation instructions and typically using a cutting guide or template. Improper installation could result in surface water contaminating the well water....