What is the difference between a traditional sediment filter & a spin-out sediment filter/ separator?

These two types of filters have the exact same purpose, they both are designed to remove sediment from your water. The information below will help you determine when you would choose one over the other and in what circumstances it would be beneficial to install both types in series.

Every filtration system includes a traditional sediment type water filter, but not every filtration setup will incorporate a spin-out type sediment filter or separator.

Traditional sediment filters including spun poly, pleated, and string wound are ideal for removing sediment, sand, silt, scale, or rust particulate matter from your water. They will perform well for this filtration as long as the sediment load is not too heavy, meaning the sediment cartridge will not become clogged to a point at which the cartridge becomes clogged. This could mean that the water flow or pressure is reduced to undesirable levels prior to the six month period at which the filter must be replaced to avoid bacteria build up.

Traditional sediment filters including spun poly, pleated, and string wound are ideal for removing sediment, sand, silt, scale, or rust particulate matter from your water. They will perform well for this filtration as long as the sediment load is not too heavy, meaning the sediment cartridge will not become clogged to a point at which the cartridge becomes clogged. This could mean that the water flow or pressure is reduced to undesirable levels prior to the six month period at which the filter must be replaced to avoid bacteria build up.

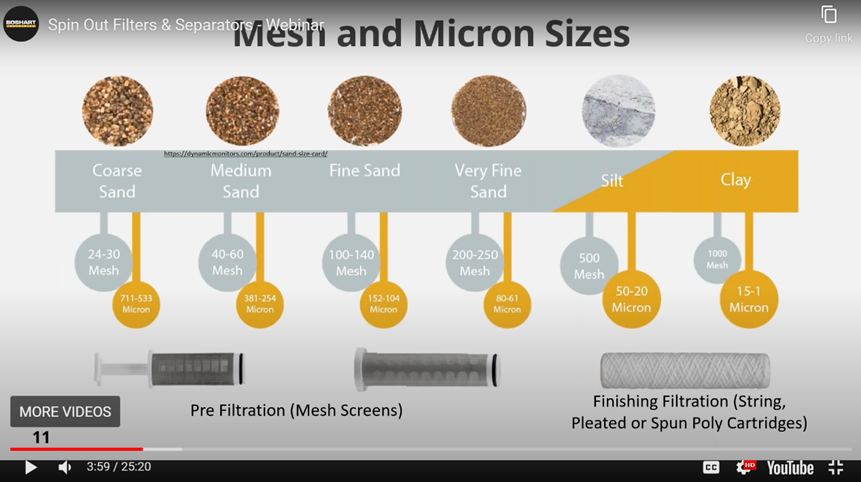

Spin-out filters can be used on their own depending on the size of particulate you wish to remove.

However, they do have limitations regarding the particulate size. The finest 1000 mesh screen will remove particulates between 15-20 microns as you will see on the chart below.

Spin-out sediment filters and spin-out separator filters both utilize stainless steel mesh filter elements which can be removed, rinsed off, and put back into use. They will reduce overall filtration costs and labor due to frequent cartridge change outs. They are ideal when heavy sediment loads are present in the water, typically from water wells which produce significant volumes of sediment and applications involving pumping from water reservoirs, lakes, and streams.

Spin-out sediment filters and spin-out separator filters both utilize stainless steel mesh filter elements which can be removed, rinsed off, and put back into use. They will reduce overall filtration costs and labor due to frequent cartridge change outs. They are ideal when heavy sediment loads are present in the water, typically from water wells which produce significant volumes of sediment and applications involving pumping from water reservoirs, lakes, and streams.

Spin-out filters are commonly installed in series with a traditional 10, 5 or lower micron rated sediment filter cartridge as a finishing filter. The spin-out filter has a purge valve which allows for quick and easy flushing of the sediment without disassembly. Removing this sediment prevents premature clogging of the finish filter, with the goal of it lasting for the six-month period at which time it needs to be changed out for bacteria reasons. This will reduce the number of sediment cartridges used in this time period. For example, if the filter clogged every two weeks this would require 12 cartridges.

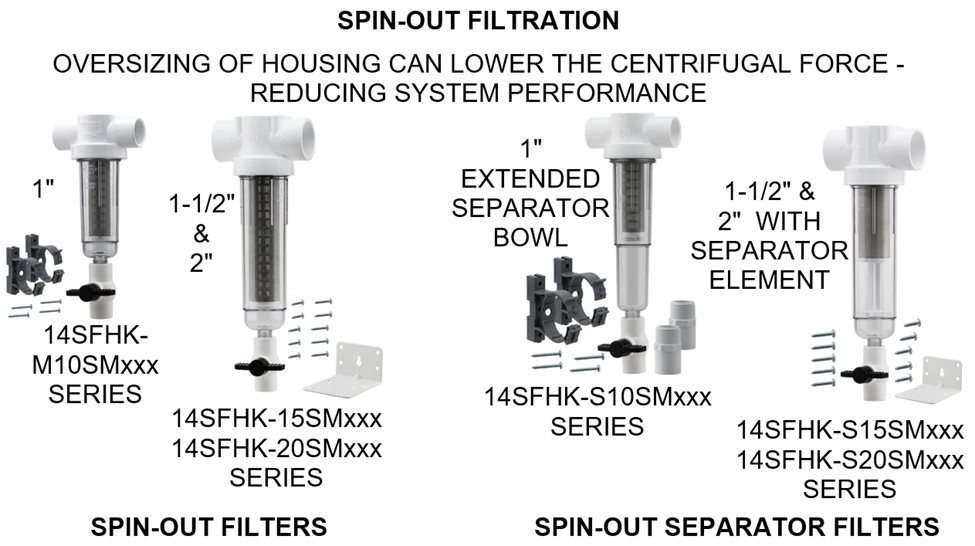

WHAT IS THE DIFFERNCE BETWEEN A SPIN-OUT FILTER AND SPIN-OUT SEPARATOR FILTER?

The difference between these filters is simply the size of the sediment chamber in which the sediment settles down into the water above the reservoir which has a rapid spinning action that separates the heavier particulate using centrifugal force. The sediment drops into this lower chamber and is separated from the spinning action to reduce abrasion and constant turbulence of the separated particulate. The separator chamber is beneficial for situations where the sediment load is extremely high.

For more information on the SPIN-OUT filter product line follow the link to our webinar below:

https://blog.boshart.com/spin-out-filters-and-separators-webinar