What the heck is 2 vs. 3 or 4 Wire Pump Cable?

What the heck is 2 vs. 3 or 4 Wire Pump Cable?

There has been allot of confusion regarding 2 wire - 3 wire - 4 wire cable descriptions / terminology over the years.

This article will explain the different methods of referring to the pump cable are used in the industry. Neither method is wrong! Some describe pump cable by the type of motor installed on the submersible pump. While others including Boshart refer to the “ACTUAL” number of wires the pump cable has, the key to understanding this is that there is an additional element regardless of whether the pump is 2 wires vs. 3 wires… The “GREEN GROUND WIRE” the ground is often not counted in the number of wires as it is not considered a “power conductor.” Thus, the confusion!

INSIGHT INTO THE SOURCE OF CONFUSION!

In days of old there was pump cable sold that did not have a “Ground” wire included. This required the installer to run an additional separate ground wire along side the pump cable to ground the pump. In some cases, this resulted in installers failing to install ground wire leaving a serious shock hazard. At that time there was actually 2 wire (BLACK / RED no ground) and two types of pump cable with a total of 3 wires B.R.G. (with ground) for 2 wire pumps and B.R.Y. for 3 wire pumps (no ground), while B.R.Y.G. was also sold for 3 wire pumps and is the norm for 3 wire pumps today!

Due to decreasing demand Boshart discontinued the sale of BRY pump cable many years ago!

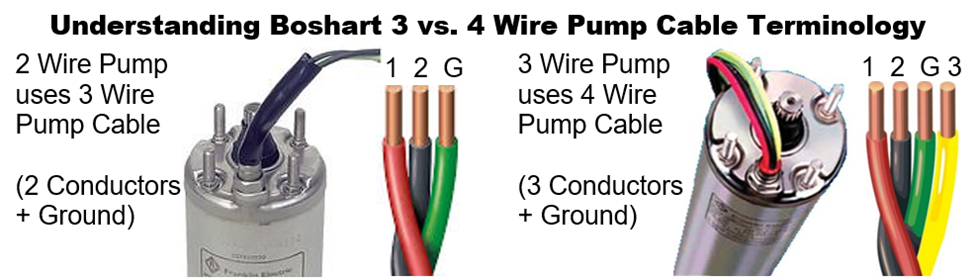

2 WIRE pump motors have 3 wires - 2 conductors BLACK, RED + a 3rd GREEN ground wire Boshart refers to this as 3 wire pump cable having a total of 3 wires – Part number for example TWU12-3G

3 WIRE pump motors have 4 wires - 3 conductors BLACK, RED, YELLOW + a 4th GREEN ground wire Boshart refers to this as 4 wire pump cable having a total of 4 wires – Part number for example TWU12-4

Which type of submersible pump is better, 2-wire or 3-wire?

There is always debate on this topic. Boshart cannot make this decision for you, we can provide information to help you make a well-informed decision, however you should discuss the options with a professional pump installer. Below are three things to consider.

#1 - Pump horsepower (HP) plays a major role in the decision, if the deep well submersible pump you need to supply sufficient water volume and pressure for your water system is sized to require a motor larger than 1-1/2 H.P., the best option is to go with a 3-wire well pump to ensure it starts and runs properly. If your application does not require a 1-1/2 or higher HP pump, then it comes down to a few other decisions.

#2 - If you want to be able to maintain and or replace the starting components of your pump without having to pull the pump out of the well in order to repair. You should select a 3-wire well pump. Three-wire pumps may have a higher initial installation cost, but you are paying to have the ability to replace individual components inside the control box and typically for a longer life expectancy of the pump.

#3 - If you wish to keep the initial installation cost down, and have a quicker and easier installation, and are understand and are OK with replacing the entire submersible pump if something major goes wrong, then an all-in-one 2-wire well pump with built in starting components may be the right choice for you.

In lower HP pumps this choice often comes down to personal preference. The only difference between 2-wire and 3-wire pumps is where the motor starting components are located.

In a 3-wire pump, the motor’s starting components are in a “control box” that is located above ground in your well house or basement.

The control box contains a large electrolytic starting capacitor, a starting relay, overload protectors and in some larger sizes a running capacitor. Depending on make there may also be microprocessor and other electronics.

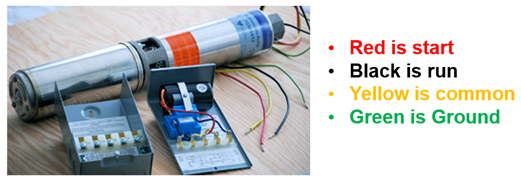

One of the functions of the control box is to energize the red for a short period of time so that the pump motor can get up to speed, after which black is switched online.

The main advantage of a 3-wire system is that if anything ever needs to be tested because of a problem, it is easier to test (and replace, if needed) the starting components that are above ground in the control box.

In contrast a 2-wire pump although a cheaper initial installation, has all the motor starting components located inside the motor which is located down in the well. Since the 2-wire system, does not have the in-house controller and has the starting capacitor hermetically sealed inside the submersed underwater down the well when it comes to repair, options are limited with a 2-wire system.

Additional Articles of Interest

https://support.boshart.com/what-gauge-of-pump-cable-do-i-need

https://support.boshart.com/do-you-offer-pump-cable-with-a-reduced-ground-wire

https://support.boshart.com/heat-shrink-splice-kit-installation-instructions-submersible-pump-cable