What size of Spin-Out Filter or Spin-Out Separator Filter should I install?

What size of Spin-Out Filter or Spin-Out Separator Filter should I install?

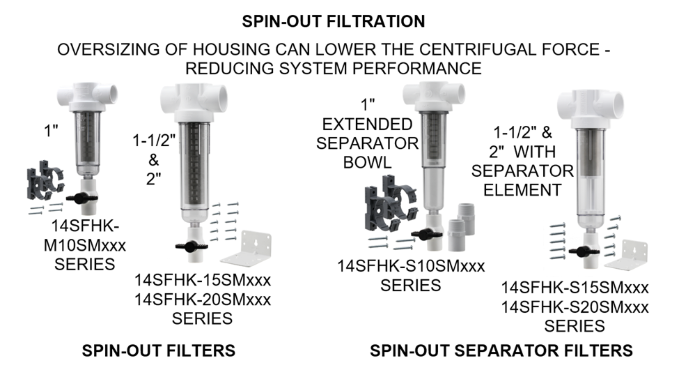

Spin-Out Filter or Spin-Out Separator Filter filtration systems have very different sizing considerations from regular type sediment cartridge type filtrations systems. Unlike typical sediment cartridge type filtration systems, the general rule of thumb that going bigger will is better is simply not the case.

This is not the case when sizing SPIN-OUT FILTERS and / or SPIN-OUT SEPARATOR FILTERS.

Spin-Out filtration uses centrifugal force to separates the sand from the water. The filter is designed to create a swirling action inside the filter bowl. The weight of the sediment forces it to the outside of the bowl due to the rapid spinning action water action. The sediment slowly drops to the bottom through slots in the filter element which separated the sediment in a storage chamber below the spinning water section.

The recommended flow rate ranges for each size of Spin-Out filter / separator filter are.

FILTER HOUSING SIZE ACCEPTABLE FLOW RATE OPTIMAL FLOW RATE

1 “ 1 – 25 GPM 5 TO 23 GPM

1-1/2” 10 – 50 GPM 23 TO 45 GPM

2” 18 – 100 GPM 45 TO 100 GPM

As you can see there is considerable overlap of flow rates for each of the 3 sizes. The normal assumption would be to recommend a 1-1/2” filter housing when the given flow rate is 20 GPM. However, the better recommendation would be to use a 1” filter housing. The systems 20 GPM flow rate is on the higher end of the rating given for the 1” filter housing but it will also ensure that there is sufficient rotation speed to create adequate centrifugal force for efficient sand separation.

If the 1-1/2” housing was used the spinning action (speed) would be reduced and there is a chance that sand will not be separated from the water as effectively even though the 20 GPM flow rate is within the acceptable parameters of the 1-1/2” filter housing.

For more information on our SPIN-OUT filtration products check out the link below.

. https://blog.boshart.com/spin-out-filters-and-separators-webinar