How does filtration work?

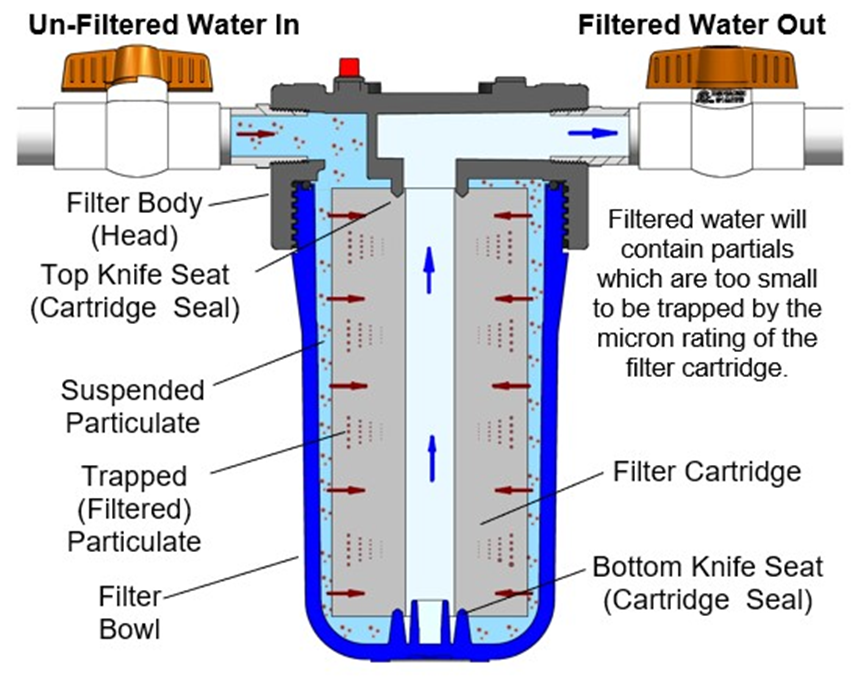

How does Traditional filtration work?

The most common types of water filtration you’ll find in residential (and some commercial) environments are traditional water filter housing with Filter cartridges installed inside. These Filter units are typically installed at the Point-Of-Entry (POE) into the home.

Unfiltered water whether the source is municipal water, or from a water well is connected to the inlet of the filter body, the flow is directed down into the filter bowl on the outside of the filter cartridge, the system pressure forces the water through the filter cartridge media into to open center core, the filtered water then flows up the center of the cartridge to the filter body, and is discharged out of the outlet connection.

The micron rating of the cartridge determines the size of particulate that will be filter out, the micron rating a measurement of the size of the pores that allow water or fluid to pass through while stopping sediment and other particulate larger than that pore size from passing through. This is the same regardless of the type of sediment cartridge spun poly, pleated polyester, or string wound all work on the same principle.

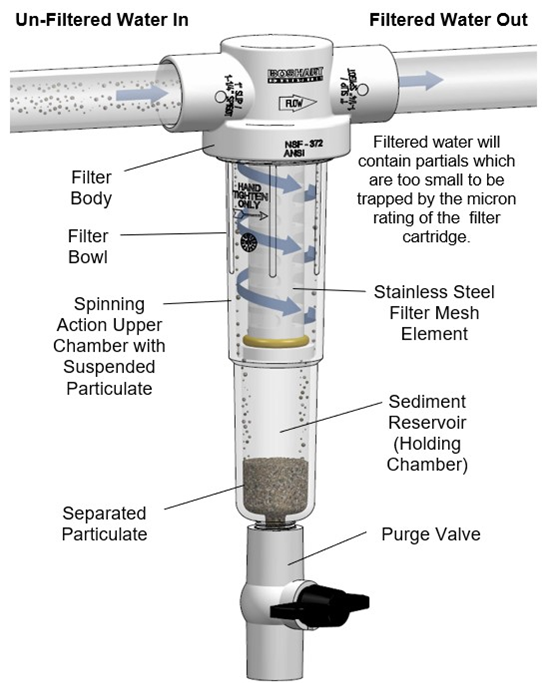

How does Spin-Out filtration work?

In some cases, there is too much sediment for a traditional water filter cartridge to handle, the cartridge will clog prematurely resulting in reduced flow and pressure loss. Requiring the cartridge to be changed prematurely, It is ideal to have the cartridge last 4-6 months at which time it must be changed to prevent bacteria build-up. If the cartridge clogs in a few weeks it will drive up your filtration costs. In these situations, the installation of a Spin-Out Sediment Filter or Spin-Out Sediment Separator Filter type filter as a Pre-Filter plumbed in series just before the traditional sediment filter is a great solution.

Spin-Out type filters have a similar flow path but operate differently than traditional water filter. Unfiltered water is connected to the inlet of the filter body, the flow is directed down into the filter bowl on the outside of the stainless-steel mesh filter element. The filter body is designed to create a rapid spinning action inside the filter bowl, the sand or silt which is more dense or heavier than water is separated from the water and forced to the wall of the filter bowl by centrifugal force, the heavy particulate slowly drops down due to the force of gravity and thru two small openings into a sediment holding chamber which separates the particulate from the spinning action in the upper chamber. The system pressure forces the filtered water through the filter mesh into to the open center core, up the center of the element to the filter body and is discharged out of the outlet connection.

Depending on the size of sediment you want to remove the Spin-Out filter may be sufficient as a 1000 mesh cartridge will remove particulate down to approximately 15 microns. It is very common that one will want to remove the finer silt or clay from the water which is accomplished by installing a second “Finishing Filter” (traditional water filter) to take out this very fine particulate, the most common types of filter cartridges for sediment removal are spun poly propylene, string-wound, pleated polyester ranging in micron ratings from 1 to 50. Whereas for improving the taste and or odor of your water , granular activated carbon (GAC), carbon block (CB), or powder activated carbon wound cartridges are the most common cartridge types ranging in micron rating of 0.5 to 10. Although other more specialized types of carbon cartridges such as the carbon briquette “Cyst” removal cartridge also exist.