What is the purpose of a torque arrestor?

What is the purpose of a torque arrestor?

A torque arrestor is designed to centralize and absorb the starting torque of a submersible pump when installed on plastic drop pipe. They keep the pump, pipe, and wire from rubbing on the sides of the well casing when the submersible pump turns on. This goes a long way in ensuring the longevity of your submersible pumping system.

A torque arrestor is designed to centralize and absorb the starting torque of a submersible pump when installed on plastic drop pipe. They keep the pump, pipe, and wire from rubbing on the sides of the well casing when the submersible pump turns on. This goes a long way in ensuring the longevity of your submersible pumping system.

Most torque arrestors are for 1" and 1-1/4" drop pipe sizes in wells that have 4" to 8" inside diameters (ID). There is a torque arrestor for 2” drop pipe that works in wells with 6" to 8" inside diameters (part no. TA20-68D-BLK). For torque arrestors that can be used on 1-1/2” drop pipes visit the link below:

https://support.boshart.com/do-you-have-a-torque-arrestor-for-1-1/2-drop-pipe

Installation Process: 7 Step-By-Step Guide

To safely and accurately install a torque arrestor, it is recommended that you have a second set of hands to help.

To safely and accurately install a torque arrestor, it is recommended that you have a second set of hands to help.

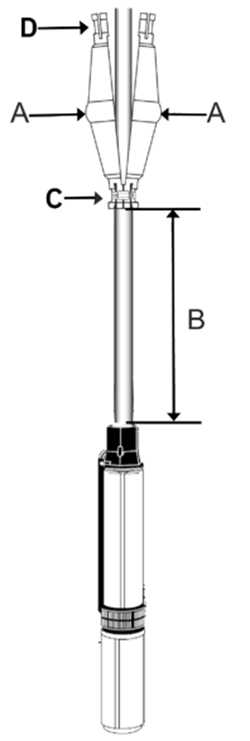

Step 1. First, place one half of the torque arrestor onto each side of the drop pipe, ensuring the drop pipe is between the evenly spaced halves (A).

It is important to ensure the first torque arrestor is placed a minimum of 18" but no more than 2' above the submersible pump (B). The second torque arrestor should then be placed at intervals of 75' to 100' above the first torque arrestor.

Step 2. You can then install the lower pipe clamp onto the torque arrestor, tightening to 60-inch lbs (C).

Step 3. Then, install the upper pipe clamp, leaving it loose.

Step 4. Grab both halves of the torque arrestor at the top (D), manually forcing them downward, causing the center section (A) to expand outward until it is slightly larger than the I.D of the well casing. You will want to ensure a snug fit to brace against the inside of the well casing. The well casing can range in diameter from four to eight inches.

Step 5. Next, hold the torque arrestor in the desired expanded position, tightening the upper clamp. It is important to ensure the upper clamp is tightened to 60-inch lbs. This will ensure the clamp does not slip when the pump is removed.

Important note: the fit must be snug enough that there is a substantial friction fit inside the casing. However, do not spread it so much that it becomes extremely difficult to insert it into the well casing.

Step 6. Now that the torque arrestor is secured in position, the pump cable and the safety rope can be inserted through the opening between the halves outside of the gear clamps. You can then secure the pump cable and the safety rope to the drop pipe above and below the clamps using cable ties.

Step 6. Now that the torque arrestor is secured in position, the pump cable and the safety rope can be inserted through the opening between the halves outside of the gear clamps. You can then secure the pump cable and the safety rope to the drop pipe above and below the clamps using cable ties.

Step 7. Make sure the pump cable and safety rope are on the outside of the torque arrestor, as seen in the picture. If the clamp shifts or slips, there could be a risk that the metal clamp would cut into the pump cable causing an electrical shortage. You have now successfully, safely, and accurately installed a torque arrestor. It should look like the picture on the right.