How do I select the proper pressure gauge range?

Pressure Gauge Range Selection

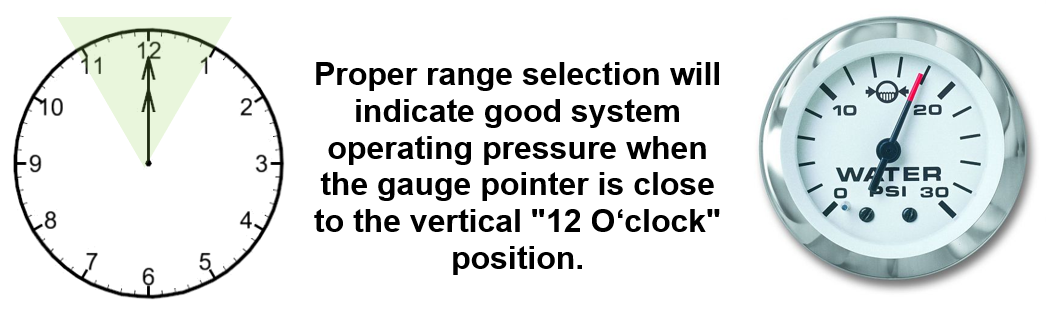

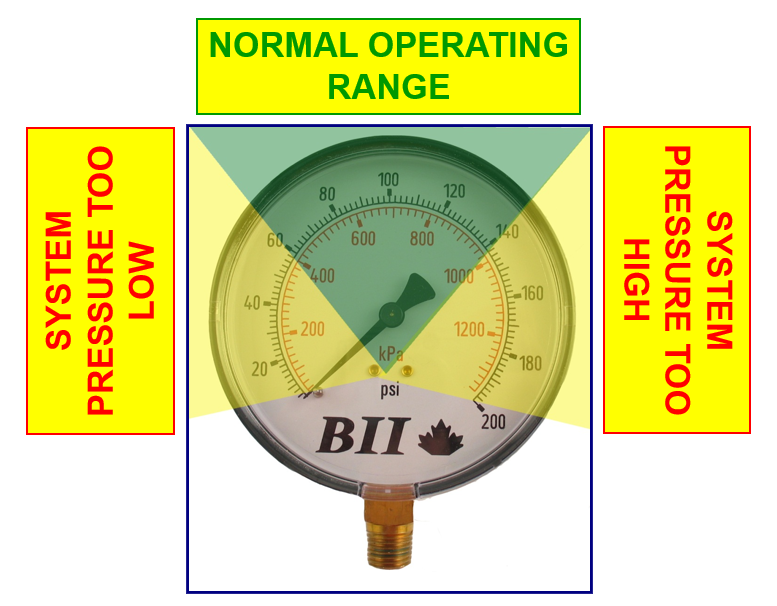

The pressure gauge selected should have a full-scale value such that the operating pressure occurs in the middle half (25% to 75%) of the scale (12 o'clock position is best). The full-scale pressure of the gauge selected should be approximately two times the intended operating pressure.

This will give the operator a visual indication of normal, ideal operating conditions when the pointer is near the 12 o'clock position. This means a "green light" condition and everything is operating the way it should be.

If, however, the "visual" of the pointer is way below or way above this 12 o'clock position, then we have a situation that needs attention.

Operating Pressure Range Engineering Consideration

Loss of Gauge Accuracy - Occurs when a gauge has been subjected to pressure exceeding design operation pressure limits. Loss of gauge accuracy results from extending the elastic element (Bourdon Tube) past its limit for elasticity.

Over Pressure Failure - Caused by the application of internal pressure greater than the rated limits of the elastic element (Bourdon Tube) and can occur when a gauge is subjected to pressures greater than design limits.