Which direction do I turn the filter bowl to loosen it when I need to replace my filter cartridge?

Which direction do I turn the filter bowl to loosen it when I need to replace my filter cartridge?

This is a question that around which, there is a great deal of confusion regarding the popular plumbing phrase Righty -Tighty and Lefty-Loosy. The principle remains the same Righty “Clockwise” to tighten and Lefty “Counter-Clockwise" to loosen.

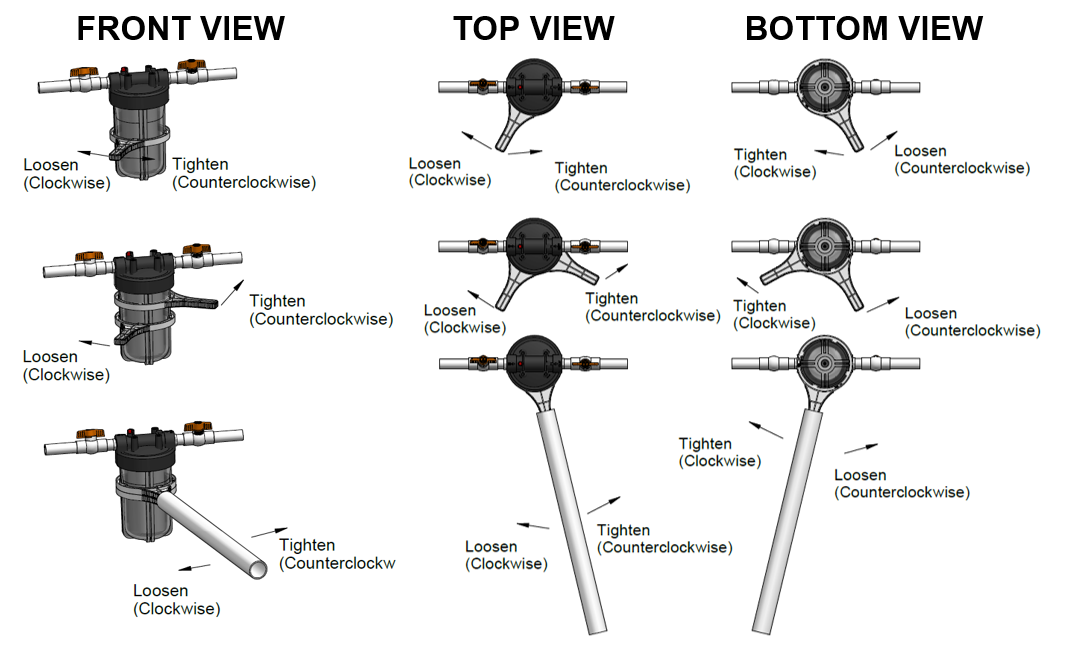

The confusion is caused by the vantage point from which to look at the filter housing. The rotation is based on looking upward at the bottom of the filter bowl (cannister). Often when a filter is installed at a POU (Point-of-Use) location such as in the cabinet below the kitchen sink, the vantage point from the top-down reverses and you must turn clockwise to loosen. This is a common cause of error and results in extreme overtightening of the bowl making it extremely difficult to loosen off.

The photos below provide clear direction for the rotation to loosen and or tighten the bowl from the front, top, and bottom vantage points.

Tight Filter Bowl Removal Tips

If the bowl has been tightened excessively and seems to be seized there are two highly effective ways to apply additional force. The use of second filter wrench as shown in the photos above can solve the problem. Option #1 – Place the wrenches on the filter bowl with the handles facing in opposite directions, from the front view you will pull towards yourself on the handle on the right while pushing on the handle on the left. This will increase the force and the filter bowl should break free with much less effort. Option #2 - If space is limited or the plastic wrench is flexing too much the second filter wrench can be placed in the same orientation with the first wrench doubling the strength. Additional leverage can then be applied by slipping an ABS or PVC pipe over the two handles to break the seized seal free.

Important Lubrication Information

Never use petroleum lubricants on O-rings. One of the common causes for the filter bowl to seize is due to the improper use of a petroleum product such as Vaseline to lube the O-ring. This causes the O-Ring to swell creating extreme pressure between the filter bowl (cannister) and the filter body (head). Only use silicone-based lubricants on the O-ring and threads. The application of a thin layer of lube on the filter bowl threads can reduce the force required to remove the filter bowl the next time you need to replace the cartridge, which should be done every 6 months.

For more information on filtration visit the Knowledge Base center at www.boshart.com

Additional Resources

https://support.boshart.com/how-to-replace-a-whole-house-water-filter-cartridge