How to Apply PTFE Thread Seal Tape

PTFE thread sealing tape is ideal for making a watertight connection on metal fitting NPT pipe joints.

WARNING: PTFE (Teflon®) thread seal tape is not recommended for making NPT threaded connections with plastic components having female threads such as Schedule 40 or 80 PVC threaded pipe fittings! Wrapping PTFE tape adds bulk and lubricates the joint, both of which increase the risk of cracking the female PVC fitting. Instead, it is suggested to use a quality thread sealing compound, such as Boshart's Gray Magic, in these applications. (See the end of this article for more information on Gray Magic Thread Sealing Compound.)

PREPARATION: Before wrapping the pipe thread make sure the threads are not damaged, are clean, and free of foreign debris.

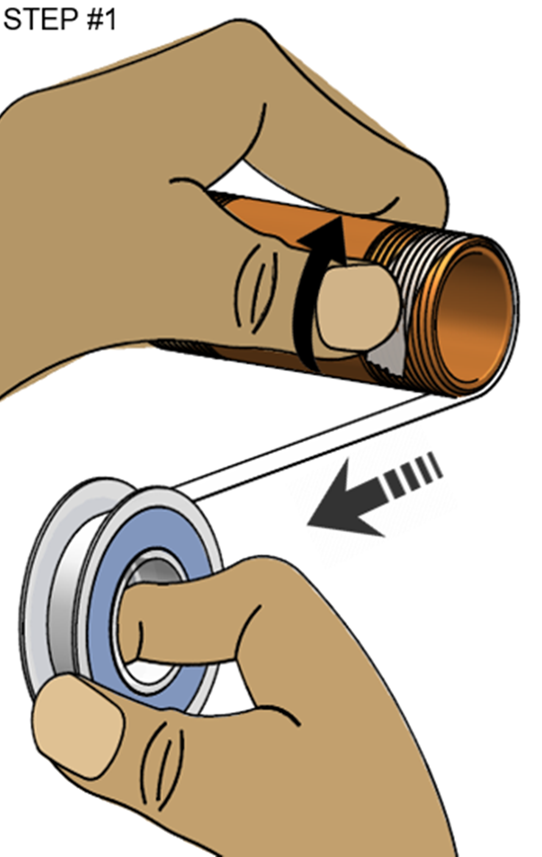

Holding the fitting or nipple in your left hand apply PTFE thread sealant tape to the male threads. Hold the end of the tape securely in place using your thumb. Pull the tape tight so that it forms into the threads and start wrapping in the direction of the threads (clockwise for right hand threads). Wrapping the pipe in the opposite direction that you will screw it into the fitting will prevent the tape from unraveling during assembly.

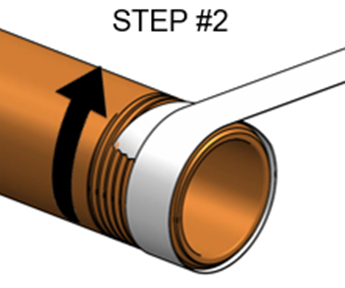

Start the first wrap by ensuring the tape fully covers the end of the thread, partially wrapping around the end of the fitting, but not covering the opening. Wrapping the entire thread will reduce the risk of seizing or galling prior to proper joint make up.

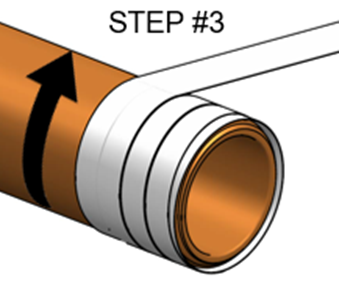

Maintain tension on the tape, ensuring that it is snugly wrapped around the thread and forms into the thread profile. Wrap the tape 3-5 revolutions and overlap the tape. Work gradually away from the end of the thread to completely cover the thread.

Typically, when using our Premium Specialty tapes (4 mil thickness “high density”) you may find that 2 wraps are sufficient when used in conjunction with a thread sealing paste. Boshart suggests that a minimum of 3 wraps for 1/8" through 2” NPT fittings is sufficient, provided the threads are all within the ANSI B1.20.1 tolerances of plus / minus 1 turn. However, if you have a male thread that is minus one turn, mated with a female thread that is plus one turn (all within spec.), an extra wrap may be beneficial.

The economy “Standard” PTFE tapes (3.5 mil thickness) typically require 4-5 wraps on 1/8" through 2” NPT fittings. The "Standard High Density” (4 mil thickness) tapes seem to be somewhere in the middle at 3-4+ wraps on 1/8" through 2” NPT fittings.

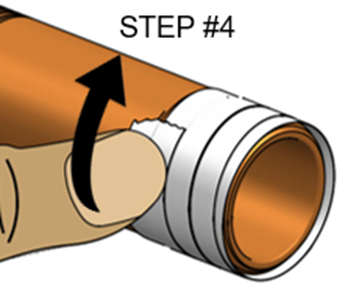

When you have finished wrapping, grip the tape with your thumb and forefinger, then pull it sharply to break the end of the tape from the spool. Then smooth the loose end of the tape over the threads so nothing is sticking up or bunched up.

TIP: After you are done wrapping you can use the edge of the spool to chase the threads forming the tape into the thread profile. This will prevent any bunching or binding when you tighten up the pipe.

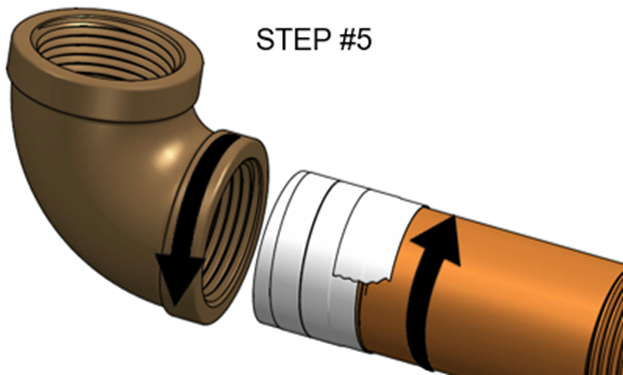

You are now ready to thread the pipe into its fitting!

Thread seal tape and thread sealing compound can be used in conjunction with one another.

Once you have the male threads properly wrapped with PTFE thread seal tape, you can apply a coating of thread sealing compound over the PTFE tape before assembling the connection. Due to NPT tapered thread designs on pipes and fittings, the tape will be compressed into the root of the thread. Since the tape’s elasticity allows it to stretch when applied, it does not completely fill the root to the crest of the thread. Applying a thread seal compound such as GRAY MAGIC on top of the tape will fill any remaining voids between the male and female threads as they are assembled. Excess joint compound will be pushed out of the fitting.

CAUTION: Only apply the thread sealing compound to the male thread in a sufficient quantity to fill the thread profiles. Applying only to the male thread ensures that the excess compound is squeezed out of the fitting, where it can be easily wiped away using a cloth. Do not apply the thread sealing compound to the female threads as the excess compound will be forced into the fitting / piping system, and you will end up with the excess compound inside your piping. The amount of compound can be adjusted. If you do not have any excess compound being squeezed out you will want to apply more liberally, however if you are having excessive compound being squeezed out there will be more cleanup and wasted compound so apply a little less.

https://support.boshart.com/making-npt-connections

https://support.boshart.com/making-a-leak-proof-stainless-steel-threaded-connection

https://support.boshart.com/gray-magic-applications