How to Clean your Spin-Out Filter

How to Clean your Spin-Out Filter

#1 - Close the shut-off valve that controls the flow to the system on the inlet side of the filter unit.

#2- Open a nearby faucet on the outlet side where the filtered water comes out to relieve the pressure from inside the filter unit.

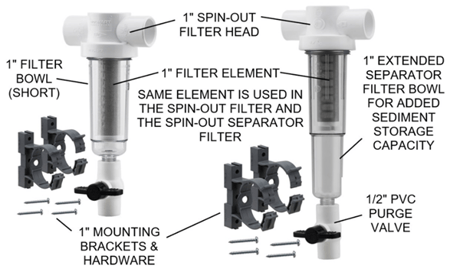

#3 – Open the purge valve to drain the filter bowl, then loosen the clear filter bowl by hand, turning counter-clockwise (use a strap wrench if necessary).

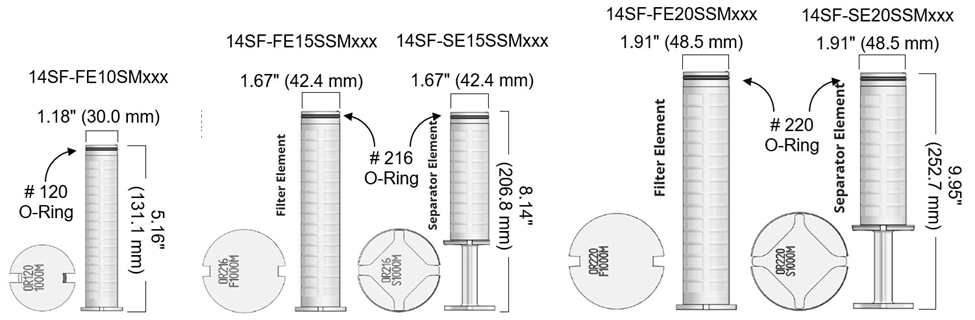

#4 - Remove the filter element (316 SS mesh screen) from the filter body. To remove, pull straight downward. If it is stuck twist back and forth / side to side gently while pulling downward. (NOTE: after cleaning apply some NSF-61 approved silicone lubricant to the O-ring before reassembly. This will prevent the O-ring from seizing in the socket.)

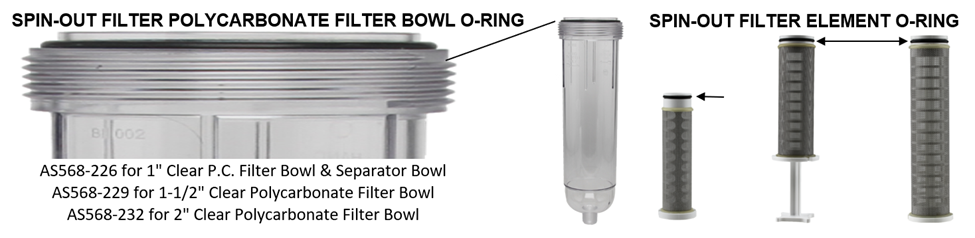

#5 - Remove the O-ring and wipe the O-ring and the seating groove clean. Clean the filter with warm soapy water and a brush. Then rinse with clean water or a water and vinegar solution.

NOTE: Some filter manufacturers recommend changing the O-ring each year; however, we have not found this to be necessary. We do suggest that you always keep a replacement O-ring on hand in case they deteriorate over time or get damaged.

#6 - Clean the white PVC filter head and clear polycarbonate filter bowl with warm soapy water and a brush. Then rinse with clean water or a water and vinegar solution.

#6b Optional - If you choose to sanitize, prepare a sanitizing solution using 1 gallon of clean water in a clean bucket. Add 1/3 teaspoon of unscented household bleach to the water and add 1 cup of this sanitizing solution to each filter housing bowl (lower part). Install the housing bowl with the sanitizing solution, without the filter element. Open the shut-off valve and allow the filter unit to fill with water. When water starts to flow out of the faucet on the outlet side of the filter unit close the shut-off valve on the outlet side. Allow water and bleach to contact the housings, lines, and faucet for 30 minutes. After 30 minutes, remove the filter housing bowl using the procedure described above: shut-off the valve, remove the filter bowl, and discard the sanitizing solution down the drain. Then, rinse with clean water or a water and vinegar solution before reassembly.

#7 – Lubricate the O-ring on the filter element with an FDA or NSF-61 approved silicone O-ring grease, then reinstall the screened filter element into the filter body (see photo below).

#8 – Lubricate the large filter bowl O-ring (see photo above) with an FDA or NSF-61 approved silicone O-ring grease, then reinstall the clear filter bowl turning it clockwise by hand.

#9 – Close the purge valve and open the shut off valves in the inlet side and run water through the cleaned filter to a close by drain for 5 minutes to flush all the sanitizer and water and vinegar solution out.

#10 - Close the faucet on the outlet side and check for leaks with the filter unit pressurized.

Task Completed!

Additional Resources:

https://support.boshart.com/14sf-series-spin-out-filter-replacement-parts

https://support.boshart.com/what-mesh-rating-do-i-need-for-my-spin-out-filter-or-separator-filter