How do I vent a liquid-filled gauge?

How do I vent a liquid-filled gauge?

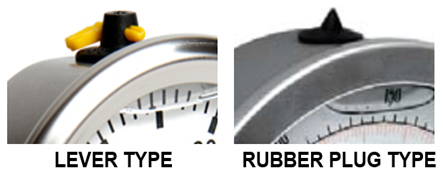

There are two types of filling plugs, some gauges are supplied with a two piece “lever” type while others are supplied with a one piece “solid” rubber type.

Gauges are supplied with a filling plug. The levers are closed on delivery and must be opened on installation in order to prevent any possible pressure build-up in the case. The lever is a half turn valve which is used to vent the gauge. By moving the valve to the open position (groove down) the gauge is allowed to breathe, releasing any pressure or vacuum built up inside the case. If the gauge is installed in an upright position, the lever can be left in the open position.

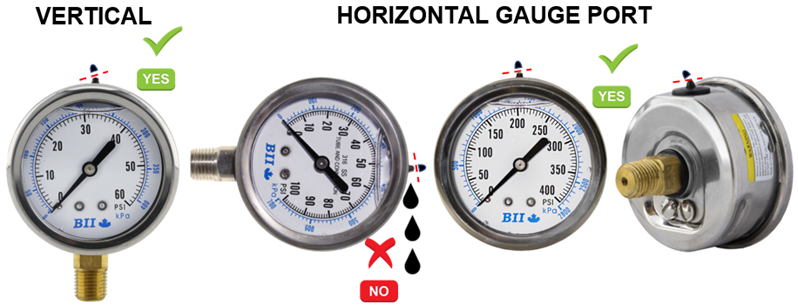

The lever also allows the use of the gauge in a non-upright position by moving the valve to the closed position (groove up) to prevent the liquid from leaking out. However, this installation is not recommended as the gauge will be inaccurate as temperatures fluctuates!

To vent solid rubber fill plugs, simply cut off the tip of the plug which will open a small hole thru which the gauge can vent.

HORIZONTAL GAUGE PORT

When a liquid filled gauge is required on a horizontal gauge port, a center back mount (CBM) gauge should be installed and oriented with the vent upwards.