What should I consider when selecting and installing a tank tee?

Tank Tee Selection & Installation Best Practices

Material Selection:

NL Brass Tank Tees are economical and preform many geographic locations. However, the use of brass tank tees should be avoided in areas where the water quality is either unknown or known to cause dezincification resulting in the accelerated corrosion of the brass components. An experienced plumber will be aware of areas where the use of brass should be avoided.

Stainless Steel Tank Tees are a great choice for areas where water quality causes corrosion on brass components or where it is unknown if dezincification of brass is a concern. For a slight premium in cost to the overall water system, you can have peace of mind with a S.S. tank tee and accessories which is highly corrosion resistant and is guaranteed to be free from dezincification concerns associated with brass.

Best Practices For Installing Tank Tees

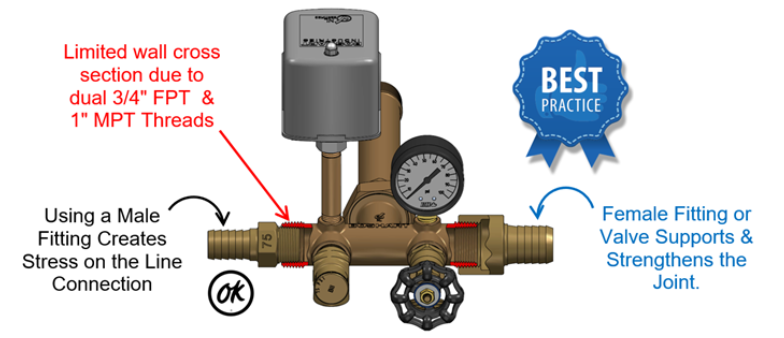

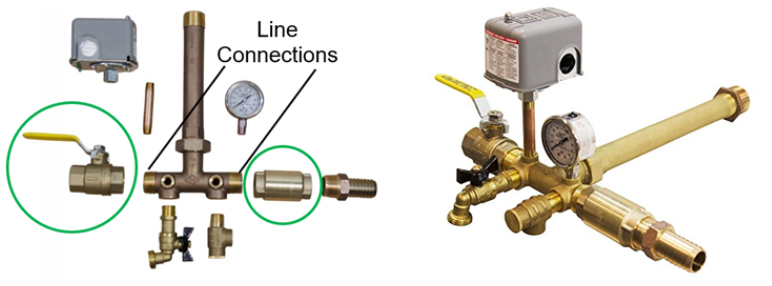

#1 – Use Female (FPT) Fittings or Valves on the Tank Tee Line Connections

The use of female fittings to make the line connections is cheap insurance against having a joint failure due to a cracked thread. Most often a cracked (split) thread is caused by one of, or more commonly a combination of the following three factors. §Overtightening §Dezincification §Use of PTFE Tape

#2 – Avoid Over Tightening – P.T.F.E. sealing compounds and tapes, make threaded joints slippery. Their use can be an invitation to over-torque.

Over tightening combined with dezincification of brass in aggressive water conditions, can increase the risk of stress cracking, often these failures occur 1 to 1-1/2 years after installation but the time frame may vary depending on how aggressively the water is attacking the brass.

The use of female threaded fittings, check valves or ball valve on the line connections will reduce the risk of stress cracking.

#3 – Use a Thread Sealing Compound

The use of quality thread sealing compound significantly reduces the potential problems that occur when a P.T.F.E. thread sealing tape is used when threading a male fitting into a female line connection. P.T.F.E. tape creates a “wedge” effect when used on NPT threads this exerts an incredible internal force, stressing the female thread.

When P.T.F.E. tape is wrapped around plastic male threads it adds to the strain and tensile stress. The tendency of some installers is to incorrectly wrap several extra layers of tape around the male threads, the added thickness further increases the stain and stress on the female thread.

#4 – Select the most durable material

If you prefer to use the female line connections for your installation, consider switching to a Stainless-Steel tank tee. The stainless material is much stronger, and much less prone to stress cracking than the softer brass alloy, in addition corrosion and dezincification issues are eliminated.