What makes the threaded connections on Boshart's industrial spool pitless units superior?

When designing our threaded connections, we set out to eliminate two common issues.

❶ Increased structural strength due to more thread engagement.

❶ Increased structural strength due to more thread engagement.

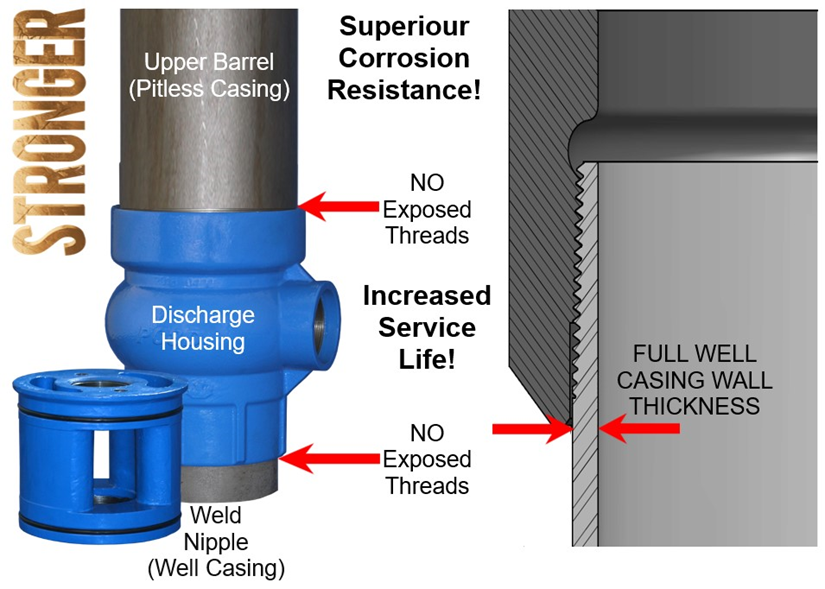

The threaded connections in the discharge housing are purposely cut deep to allow the full thread of the mating weld nipple or upper barrel to be fully buried in the housing. Since the wall thickness increases as the thread tapers, the more threads engaged, the stronger the joint becomes, reducing the risk of structural failure.

❷ Longevity!

The remaining threads are inside the recessed pocket which makes for easy alignment and starting of the threads. This annular space is fully filled with sealant to keep moisture or dirt from entering the gap. Only the full casing wall is exposed to the soil and protective coatings remain intact. This is by far superior to bare metal at cut threads being exposed with only 50% of the original wall thickness remaining. This would result in accelerated corrosion being reported in some areas. The life expectancy is greatly increased as it will take over 2 times longer for the threaded connections on a Boshart pitless unit to corrode through compared to the threaded connection on our competitors' units which have exposed threads.

BENEFITS…

❶ More installation options - They can be…

- threaded directly to the well casing.

- welded to the well casing with the supplied weld nipple.

- adapted to a flanged connection.

- adapted to use a mechanical quick connect (EBAA IRON Mega Flange).

❷Widely accepted - Some well codes or AHJ do not allow a buried flanged connection.

❸ Competitive – Direct welding to casing eliminates the cost of flanges at well casings and upper barrel pitless casing connections.

Additional Resources:

https://support.boshart.com/what-is-a-spool-type-industrial-pitless-adapter

https://support.boshart.com/do-the-spool-type-industrial-pitless-adapter-units-have-hold-down-hooks

https://support.boshart.com/how-do-i-install-a-wtcl-c-series-industrial-well-cap

https://support.boshart.com/how-do-i-install-a-spool-type-industrial-pitless-unit

Municipal & Industrial Pitless Well Systems Installation guide:

Municipal & Industrial Pitless Well Systems Installation guide:

All information on pitless units is available in the Municipal and Industrial Pitless Well Systems booklet.