What are the connection options for the industrial spool pitless unit discharge housing?

What are the connection options for the industrial spool pitless unit discharge housing?

What are the connection options for the industrial spool pitless unit discharge housing?

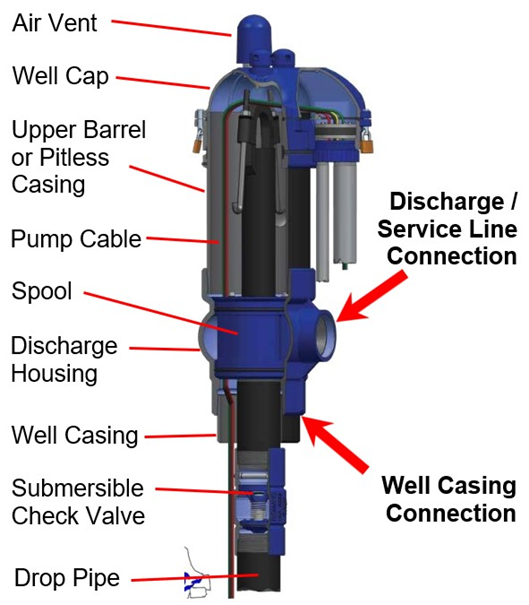

A variety of options are available to enable the installer to connect the pitless unit to the well casing and to the service pipe. In this article we will cover the options and how they are ordered using the pitless unit order forms.

Well Casing Connection Options:

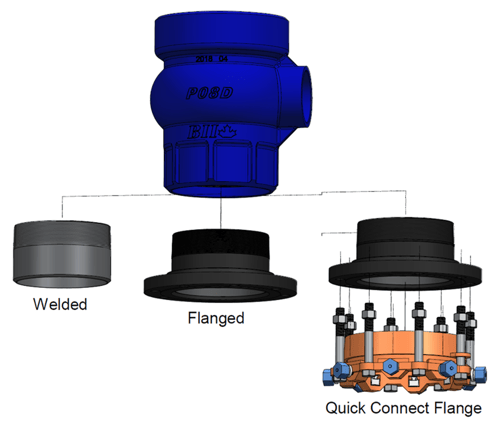

Welded: Pitless units are supplied with the standard MPT x beveled end adapter for welding the unit directly to a steel well casing.

Flanged: When a flanged connection is desired, a MPT x flanged adapter can be ordered. These are ideal when the installer is using a PVC well casing and would like to connect by means of a PVC flange. In some cases, the installer will weld a flange to the steel well casing and chooses this option to connect the unit to the well casing instead of the traditional direct welding.

Quick Connect: Flanges are a great solution for installations where it is not practical to weld on site. The quick connect MEGA Flange provides a secure and watertight connection using basic tools.

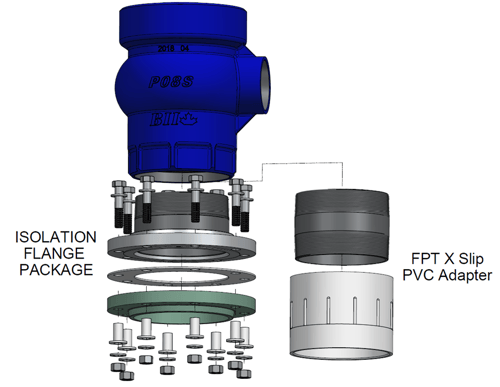

Isolation Flange Package: When joining dissimilar metals, typically a 304 Stainless Steel industrial pitless to a steel well casing, it is highly recommended to use an isolation flange kit to avoid the risk of galvanic corrosion.

Nipple & PVC FPT x slip adapter: When joining a pitless unit to a PVC well casing, a less expensive alternative to using the flanged system is to use a nipple and PVC adapter. This is less expensive but great care must be taken to not overtighten the FPT connection. This will result in stress cracking of the FPT connection on the PVC adapter. The flanged connection is the superior option.

Discharge connection options:

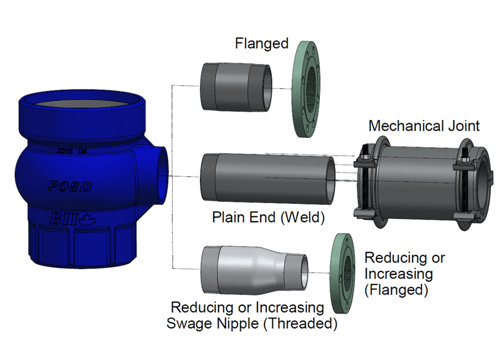

Flanged: When a flanged connection is desired, a nipple and FPT flange can be ordered. These are ideal when the installer is using HDPE service piping and would like to connect by means of a HDPE flange or ring assembly.

Mechanical Joint (MJ) Connection: Mechanical couplings are a great solution for installations where it is not practical to weld on site. The MJ couplers are used in conjunction with a plain end nipple to provide a secure and watertight connection using basic tools. They allow for some deflection of the connection to compensate for shifting soil conditions.

Plain End Welded: Plain end (beveled) nipples can be purchased for welding a steel service line directly to the unit.

Swage Nipple: When the discharge needs to be reduced to a smaller diameter service line, the use of a swage nipple is recommended. The swaged profile minimizes turbulence and friction loss. Swage nipples are also used when the service line is transferring the water a great distance and a larger diameter service line is required to reduce friction loss on the long run of piping. The Swage nipple can be fitted with a flange to provide additional installation options such as the HDPE flange.

Ordering:

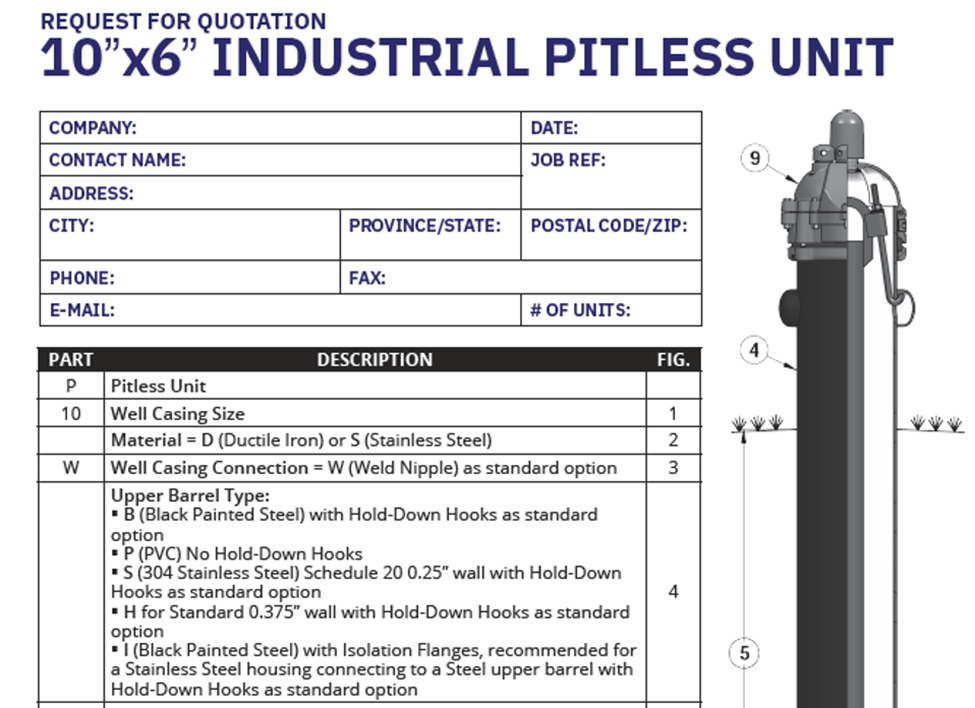

The types of connections and other accessories, which are sold separately, are listed on our 3-page order form. The order form is designed to walk you through the selection process in a logical fashion which ensures all of the required information is provided to get a complete and accurate quotation.

The first page will prompt the customer or engineer to fill in the following 5 categories:

❶Pitless Adapter Material: “D” for Ductile Iron or “S” for 304SS

❷Upper Barrel Construction: "B" for Black Painted Steel with Hold-Down Hooks, "P" for PVC, "S" for 304SS, "H" for Standard 0.375" wall with Hold-Down Hooks or "I" for Black Painted Steel with Isolation Flanges

❸Bury Depth: 3,4,5,6,7,8,9,10 (or 0 = no upper barrel) in feet

❹Spool Type: “N” for Normal Well or “F” for Flowing Well

❺Well Cap: “C” for Cast Iron or “N” for No Cap

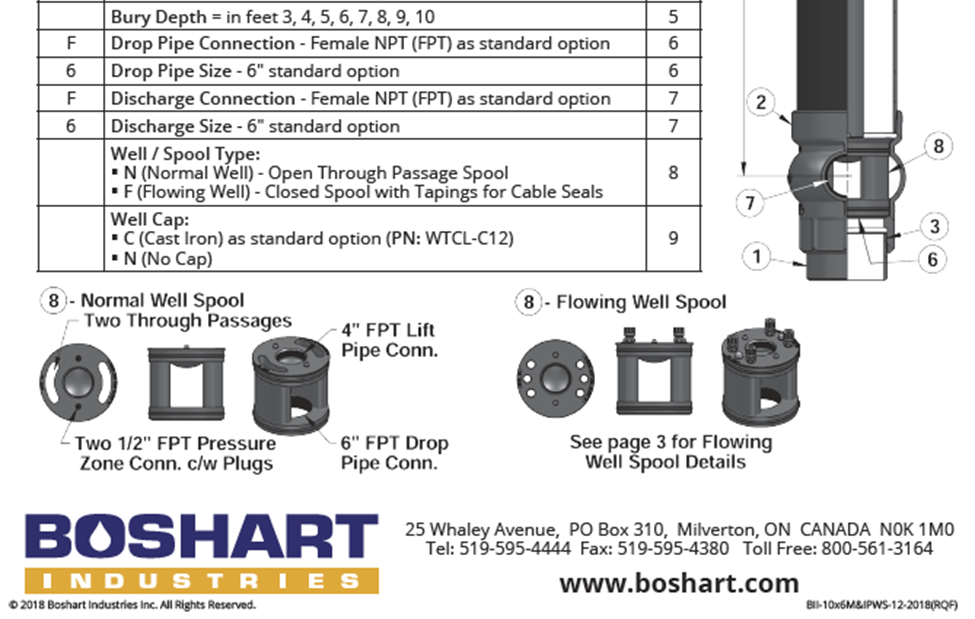

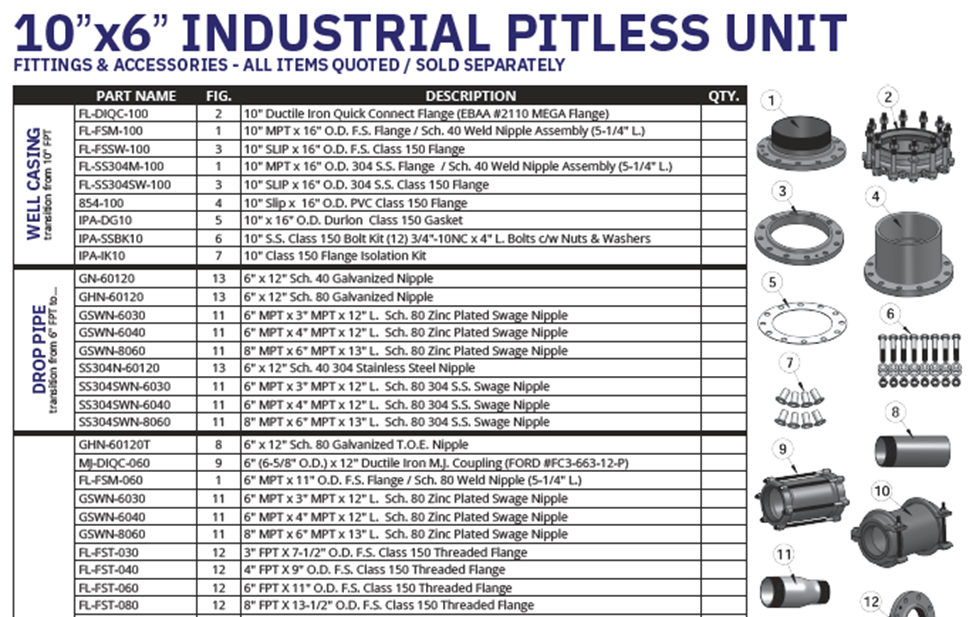

On the second page there will be a complete list of part numbers for accessories and fittings which are available to convert the well casing, discharge or drop pipe connections to something other than the standard threaded connection.

The fittings will be priced and sold as separate items from the pitless unit.

The standardization of base models will allow for having pricing for the basic pitless unit models. This eliminates the need to price each pitless unit on a case-by-case basis depending on which additional fittings are selected to make the final connection to the well casing, discharge, and drop pipe.

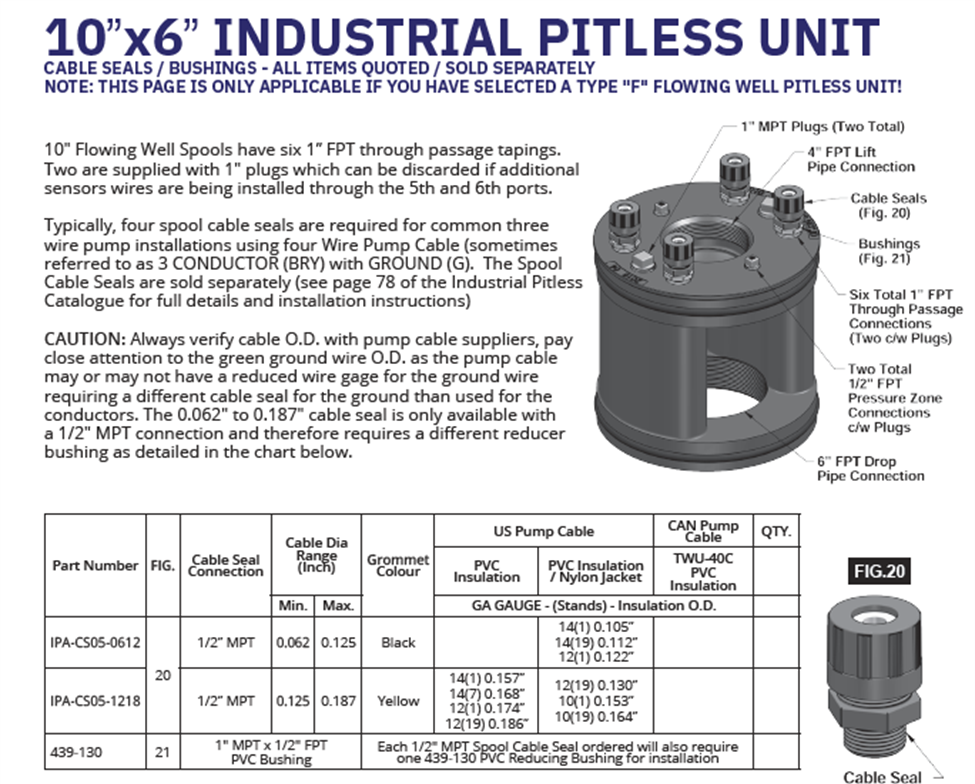

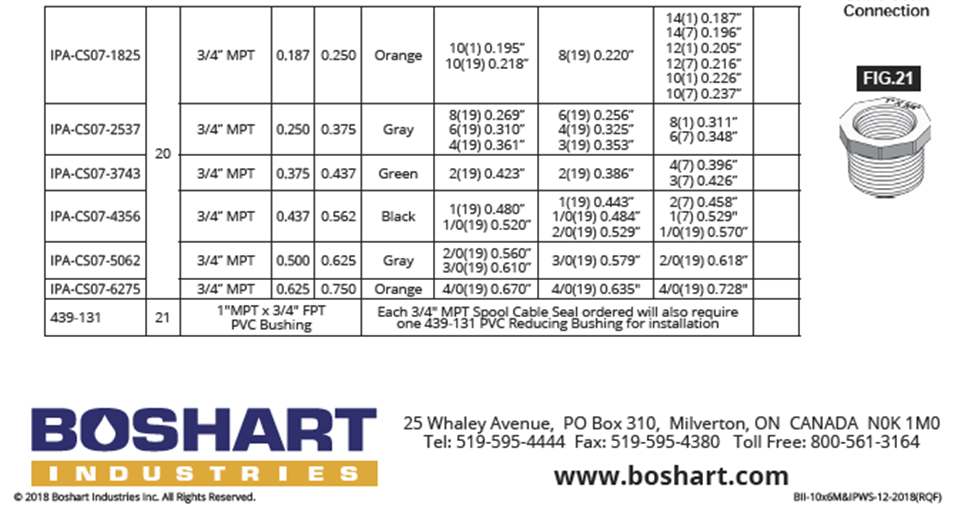

The third page is only used for flowing well pitless units. It has information on cable seals for sealing the power cables through the spool in flowing well applications. The type and AWG size of the pump cable being used in the installation is required to make a proper selection. Often this information is not yet available when the pitless unit is being ordered. For this reason the cable seals often need to be ordered later when the submersible pump and pump cable requirements are finalized.

The cable seals are priced and sold as separate items from the pitless unit.

Additional Resources:

https://support.boshart.com/what-is-a-spool-type-industrial-pitless-adapter

https://support.boshart.com/do-the-spool-type-industrial-pitless-adapter-units-have-hold-down-hooks

https://support.boshart.com/how-do-i-install-a-wtcl-c-series-industrial-well-cap

https://support.boshart.com/how-do-i-install-a-spool-type-industrial-pitless-unit

To access the Municipal and Industrial Pitless Well Systems Installation guide use the link below: