What is a well seal elbow and for what is it used?

Well seal elbows are simply 90° long bend, “sweep” elbows which are designed for polyethylene (PE) pipe. The long, sweeping bend reduces friction loss so that your deep well jet pump will run as efficiently as possible.

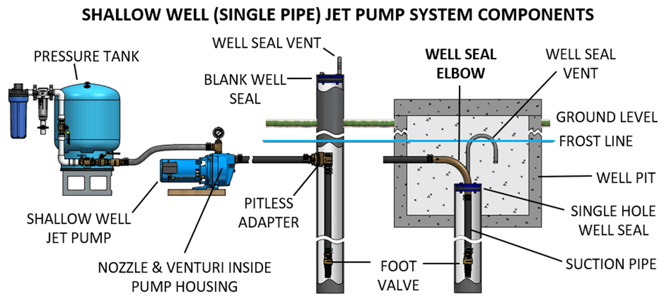

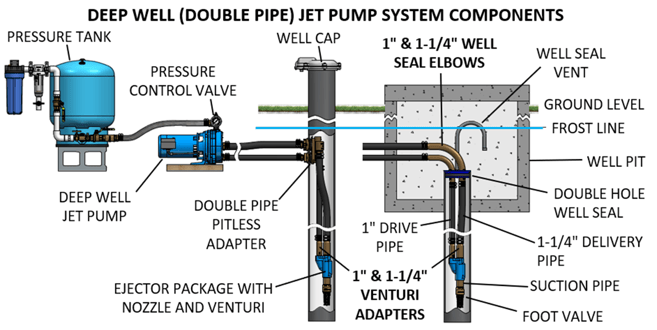

Well seal elbows are typically used in well pits to make directional changes from the vertical pipes down the well, to the horizontal service lines, to the pump house or residence. They can be used in both shallow well and deep well jet pump installations. Deep well (double pipe) systems with an ejector package down the well use two elbows: a 1” for the drive pipe and a 1-1/4” for the delivery pipe. Alternatively, a shallow well jet pump system only uses a single elbow on the suction pipe.

The diagrams below detail both deep and shallow well jet pump installations. Shallow well jet pumps have a jet ejector (nozzle and venturi) located in the pump housing. They can pump water from 0’ to 25’ deep, whereas a deep well jet pump can typically pump water from 25' up to 120'. The jet ejector nozzle and venturi are located in the well below the water level.

The diagrams also show how well seal elbows are used in well pit installations compared to Pitless adapters. Well pits are not nearly as common as they were years ago. Some well codes mandate that well pits must be converted with a well casing extension and a Pitless adapter which is more sanitary and protects your well water from surface water contamination. Well seal elbows are declining due to the use of Pitless adapters.

The link below provides more detailed information on the difference between well pits and Pitless adapters.

https://support.boshart.com/how-did-the-pitless-adapter-get-its-name

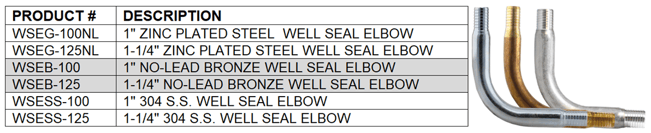

Zinc plated steel, red brass (bronze), and 304 S.S. materials are available.

Polyethylene (PE) Pipe Connections:

In a water well installation or for direct burial of water lines, where maximum corrosion resistance is required, only the best All 300 Grade Stainless Steel clamps should be used to ensure that the clamp will last the lifetime of the system.

In a water well installation or for direct burial of water lines, where maximum corrosion resistance is required, only the best All 300 Grade Stainless Steel clamps should be used to ensure that the clamp will last the lifetime of the system.

For maximum corrosion resistance use the 87-Series All 300 Grade Stainless Steel clamps. This series of clamps is marine grade and contains a high nickel content which provides strong corrosion resistance.

Additional resources:

https://support.boshart.com/what-is-a-venturi-adapter-and-for-what-is-it-used

https://support.boshart.com/what-components-are-used-in-a-shallow-and-deep-well-jet-pump-system

https://support.boshart.com/what-type-of-poly-pipe-are-insert-fittings-designed-to-work-with

https://support.boshart.com/what-is-a-water-well-system