How did the “Pitless Adapter” get its name?

The name “Pitless Adapter” was derived from a change in well construction practices many years ago.

In the days of old…

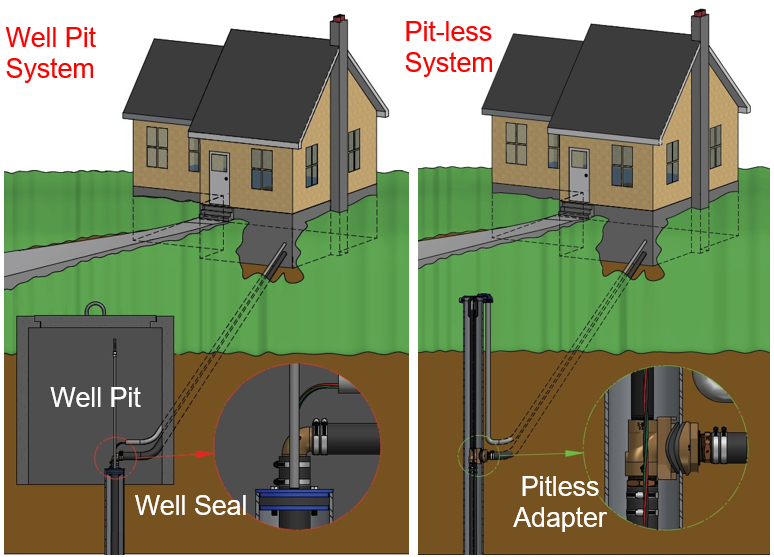

The connection from the water well to the service line was made in a “well pit”. The pit was required so that the installer could manually assemble/disassemble the pipe fittings, which connected the drop pipe to the supply pipe below the frost level. These connections were typically made using well seals and well seal elbows 3-8 feet down in a cement or wooded well pit. The installer would need to climb down into the well pit to make the connections. This system was truly the PITS!

Change for the better!

Change for the better!

The first quick connect systems used to eliminate the unsanitary well pits were introduced in the mid to late 1950s.

These “Quick Connector Adapters” got their name from the simple fact that they eliminated the need for the well pit, and this is how the name PIT-LESS adapter came to be. It’s as simple as that!

For many younger people in the water well industry, the well pit is simply something they have never seen, so the name seems a little strange until you know the history. Since that time the well pit has for the most part disappeared.

Today, most well construction codes do not allow for the use of well pits. In the past 10-2o years, there have been several government grants to convert well pit systems to the sanitary pitless adapter system.

Additional Resources:

https://support.boshart.com/how-do-i-properly-install-my-pitless-adapter

Well Construction Information

https://www.health.state.mn.us/communities/environment/water/docs/wells/construction/handbook.pdf

https://dnr.wi.gov/files/PDF/pubs/DG/DG0085.pdf