What is a venturi adapter and for what is it used?

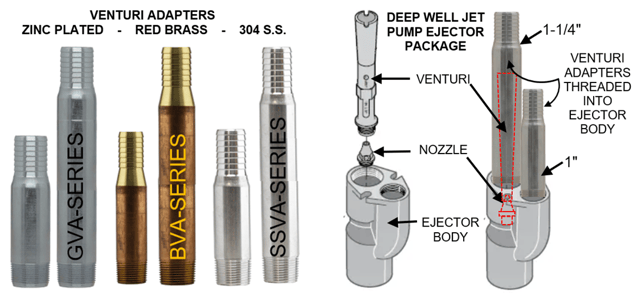

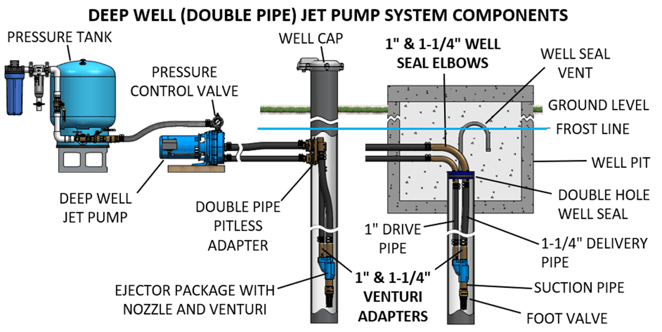

Venturi adapters are used in deep well jet pump applications. These adapters are threaded into the deep well ejector package supplied by the pump manufacturer. The ejector package consists of an ejector body, nozzle, and venturi tube.

Venturi adapters look like an extended swaged insert adapter. However, the extra-long barrel serves a purpose, which is to allow for the insertion of a venturi, hence the name. The diagram above shows how the adapter is threaded onto the ejector with the venturi tube extending up into the barrel of the venturi adapter.

The ejector body, with the nozzle and venturi tube, is installed at the bottom of the drive and delivery pipes down in the well.

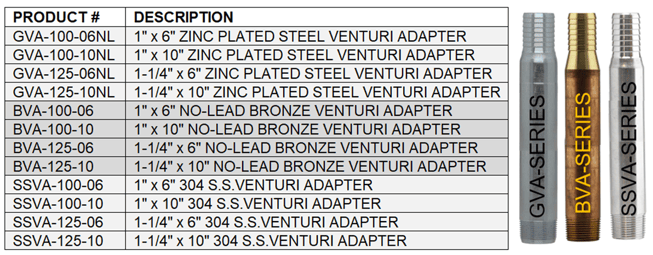

Venturi adapters are available in 1” and 1-1/4” sizes. The 1” size is used on the smaller diameter drive pipe and the 1-1/4” on the larger diameter delivery pipe.

How a Deep Well Ejector Works

Water is pumped by the deep well jet pump located at the ground surface. They can typically pump water from 25’ up to 120’. The jet ejector (nozzle and venturi) is typically located in the well below the water level.

Water is pumped by the deep well jet pump located at the ground surface. They can typically pump water from 25’ up to 120’. The jet ejector (nozzle and venturi) is typically located in the well below the water level.

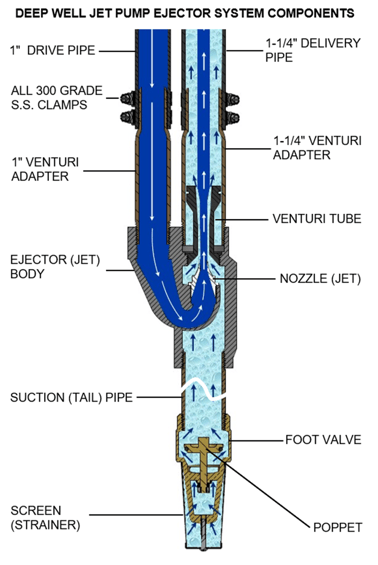

The water must be recirculated to draw water from the well. For example, suppose 4 gallons of water is pumped down the well through the drive pipe (smaller pipe), into the ejector body, making a 180° U-turn. It is then jetted through the nozzle into the venturi tube which is inside the 1-1/4” venturi adapter. Forcing the water through the nozzle increases the velocity of the water creating a vacuum. The vacuum draws in an additional 1 gallon of water from the well up through the foot valve and suction pipe. The 5 gallons of water is pumped up to the surface in the larger diameter delivery pipe. 1 gallon of water is delivered to the pressure tank. To get 10 gallons of useable water, 40 gallons of water must be recirculated down the drive pipe.

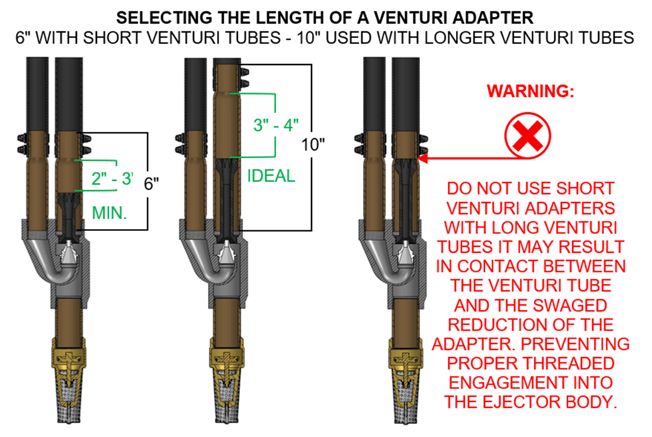

Venturi Adapter Length Selection:

A common question we get asked is why there are two different lengths of venturi adapters, 6” and 10”? The different lengths are to accommodate different size venturi tubes. 6” adapters will work for some short venturi tubes and longer venturi tubes will require the 10” venturi adapter.

Select a venturi adapter that will provide a minimum of 2" to 3" between the top of the venturi tube and the swage (reduction in diameter) of the venturi adapter. 3” to 4” is ideal to minimize turbulence and friction loss. It is important to make sure the end of the venturi tube will not make contact with the venturi adapter when it is threaded into the ejector body. If there is any doubt, select the longer 10” venturi adapter to be safe. The use of a longer venturi adapter will not cause any harm!

Zinc plated steel, red brass (bronze), and 304 S.S. materials are available.

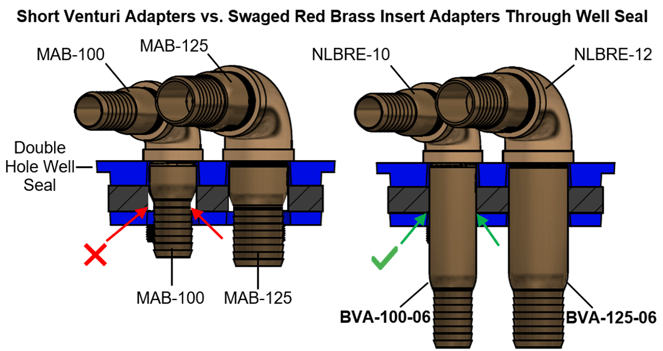

6” Long Venturi Adapter Applications

The short 6” venturi adapters can always be used on the drive pipe side. They are also commonly used to make a good seal in a well seal gasket. Some installers choose to use the short venturis in conjunction with threaded 90° elbows and insert adapter fittings instead of using well seal elbows. The longer barrel ensures the full diameter of the barrel goes through the well seal so that a water-tight seal is achieved. This also makes installation of the PE piping below the seal easier. Standard swaged insert fittings are too short for this application.

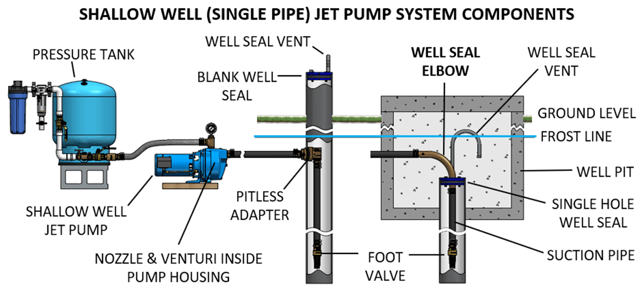

As mentioned above, venturi adapters and threaded elbow fittings can be used in place of well seal elbows or standard swagged insert adapters to go through the well seal. Similarly, the venturi adapter and threaded elbow fitting could be used in place of the well seal elbow in a well pit installation to go through the well seal. The diagram below shows how well seal elbows can be used in well pit installations.

However, well pits are being used less and less. In some areas they must be updated with a Pitless adapter, which is a more sanitary installation and protects your well water from surface water contamination. For this reason, the use of well seal elbows is declining. Refer to our article on well seal elbows for more information.

The link below provides more detailed information on the difference between well pit and Pitless adapter installations.

https://support.boshart.com/how-did-the-pitless-adapter-get-its-name

Polyethylene (PE) Pipe Connections:

In a water well installation or for direct burial of water lines, where maximum corrosion resistance is required, only the best All 300 Grade Stainless Steel clamps should be used to ensure that the clamp will last the lifetime of the system.

In a water well installation or for direct burial of water lines, where maximum corrosion resistance is required, only the best All 300 Grade Stainless Steel clamps should be used to ensure that the clamp will last the lifetime of the system.

For maximum corrosion resistance use the 87-Series All 300 Grade Stainless Steel clamps. This series of clamps is marine grade and contains a high nickel content which provides strong corrosion resistance.

Additional resources:

https://support.boshart.com/what-is-a-well-seal-elbow-and-for-what-is-it-used

https://support.boshart.com/what-components-are-used-in-a-shallow-and-deep-well-jet-pump-system

https://support.boshart.com/what-type-of-poly-pipe-are-insert-fittings-designed-to-work-with

https://support.boshart.com/what-is-a-water-well-system