What components are used in a shallow and deep well jet pump system?

What components are used in a shallow and deep well jet pump system?

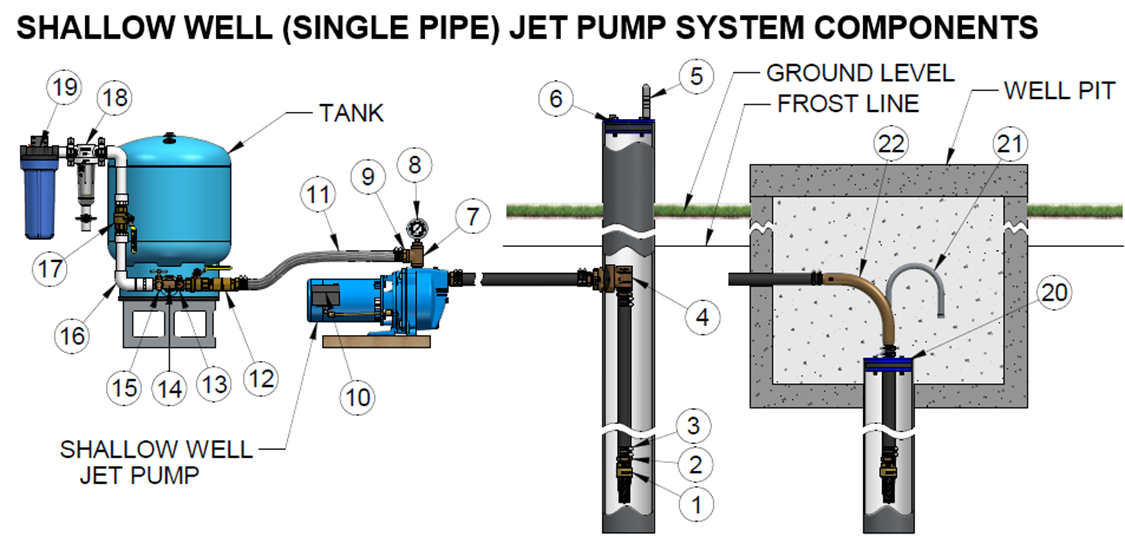

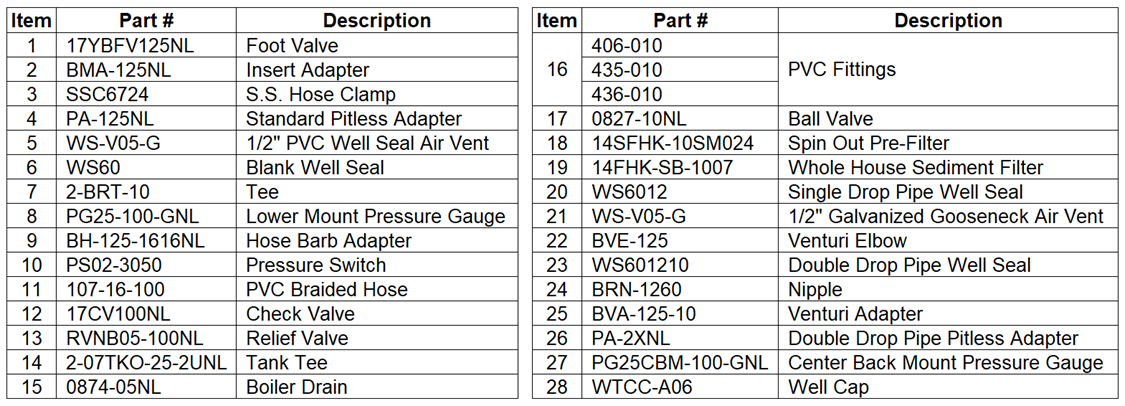

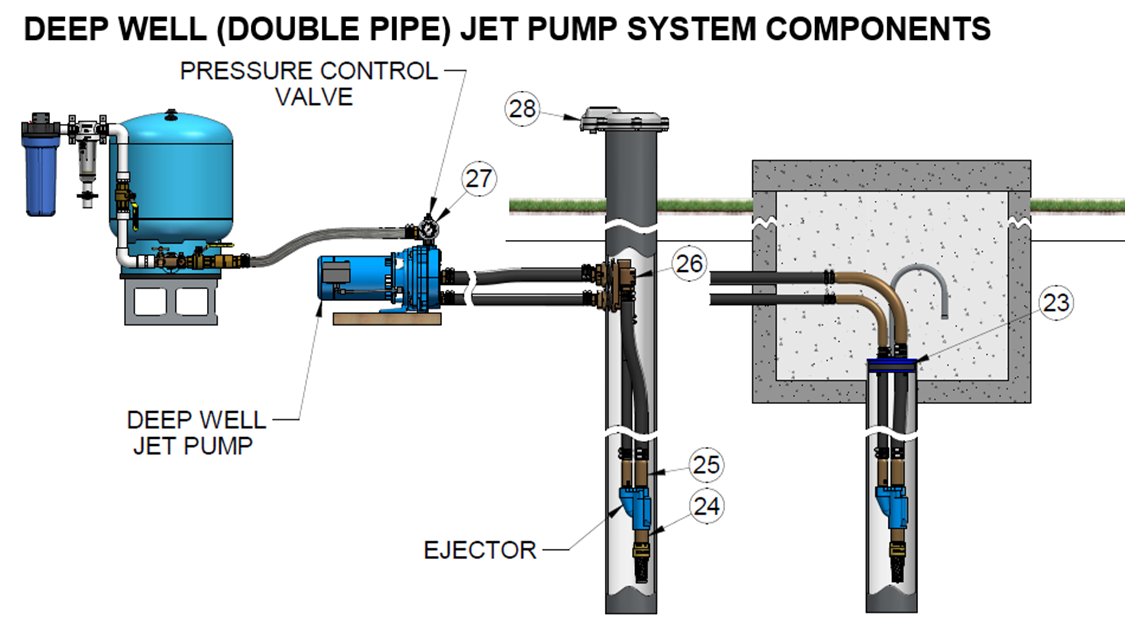

Jet Pumps are always mounted above ground in the home or in a pump house and in some cases they are installed in the well pit. The diagrams below illustrate the components used in both “SHALLOW” well and “DEEP” well jet pump systems.

The difference between a shallow well and a deep well jet pump is the depth which they can pump water from. Shallow well jet pumps use suction to draw water from shallow wells up to a maximum of 25 feet. Deep well jet pumps are capable of pumping water from depths up to approximately 200 feet.

The most common type is the shallow well jet pump which is used to draw water from a well through a suction pipe no deeper than 25 feet, making them a viable choice in areas with high water tables. They are most commonly used to provide potable water for domestic water pressure systems. However, they are not limited to potable water systems, as they are also used in irrigation and sprinkler systems. Note that the maximum pumping depth may be decreased due to altitude which will affect the maximum depth from which a shallow well pump can draw water from.

If your home has an existing jet pump, you can easily determine whether it is a shallow well or deep well pump by checking if you have one pipe (shallow well) or two pipes (deep well) from the pump going out to the well.

Photos of the components are at the end of this article for visual reference.

Photos of the components are at the end of this article for visual reference.

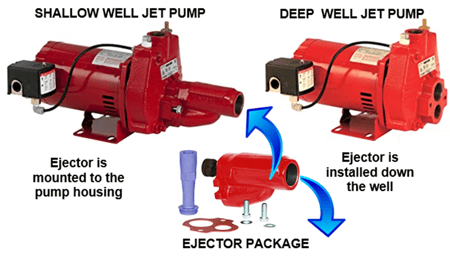

Deep well pumps are also referred to as convertible jet pumps. This means that the pump can be used as either a shallow well jet pump or a deep well jet pump. In shallow well systems, the ejector (or jet) is built in or attached to the pump above ground. For deep wells, the ejector is installed down in the well. The water force through the ejector kit draws in additional water through the foot valve attached to the bottom of the ejector body.

IMPORTANT:

IMPORTANT:

Jet pumps must be primed before they are started. Running a jet pump dry will very likely permanently damage the pumps impeller and diffuser.

Jet pumps must be primed before they are started. Running a jet pump dry will very likely permanently damage the pumps impeller and diffuser.

How to prime your jet pump:

STEP #1 - Make sure the electricity to your pump is off.

STEP #2 - Next, remove the priming plug on the wet end of the pump (or the side opposite the motor).

STEP #3 - Fill the priming vent with water until it reaches the top of the vent. The idea behind this is to remove all the air from the pump housing.

STEP #4 - With the pump fully primed, turn the power back on to the pump. Priming completed.

NOTE: If the pump does not draw water within four to five minutes you will need to re-prime the pump.

Deep Well Jet Pumps vs. Submersible Pumps

Deep Well Jet Pumps vs. Submersible Pumps

When it comes to efficiency, submersible well pumps are the clear winner!

The reason why deep well jet pumps are not as efficient as submersible pumps is because it is more cost effective to push water to the surface with the pump installed down the well. Water recirculation is not required. Every gallon of water pumped by a submersible well pump is useable water.

Deep well jet pumps need to pump and recirculate 3 to 4 gallons of water for every gallon that is supplied to your pressure system. This means you are constantly pumping 4 gallons of water in a loop to bring up the 5th gallon that is useable. The friction loss is significantly higher due to the additional length of piping required in this double pipe system. Deep well jet systems require two pipes, one for the water being pumped down to the ejector assembly and a second, larger pipe, to bring the recirculated (plus the additional water that is drawn in from the well) water back up the pipe to the surface. The energy cost to constantly recirculate water is simply lost money.

Additional Resources:

https://support.boshart.com/what-is-the-function-of-each-well-water-pressure-system-component