How do you make a secure connection between a barbed insert fitting and poly pipe using gear clamps?

How do you make a secure connection between a barbed insert fitting and poly pipe using gear clamps?

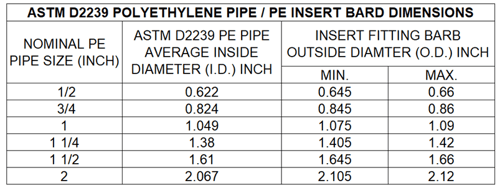

Following the best practices in the five steps listed below when making connections to ASTM 2339 poly pipe (PE) will eliminate the chance of a leak or pipe blow off failure. Following these basic principles is extremely important when the connection is under stress such as the weight of the pump or pump column in a submersible pump installation.

Following the best practices in the five steps listed below when making connections to ASTM 2339 poly pipe (PE) will eliminate the chance of a leak or pipe blow off failure. Following these basic principles is extremely important when the connection is under stress such as the weight of the pump or pump column in a submersible pump installation.

https://support.boshart.com/what-type-of-poly-pipe-are-insert-fittings-designed-to-work-with

STEP #1 – Select a high-quality insert fitting!

STEP #1 – Select a high-quality insert fitting!

CAUTION: Not all insert adapters are made equal. These tensile test results are based on tests performed on BOSHART insert fittings, which have tightly controlled barb profiles and outside diameters to ensure maximum gripping power. We cannot say the same for all insert fittings that are on the market today.

https://support.boshart.com/barb-o.d.-dimension-for-poly-pipe-pe-insert-fittings

WARNING: When selecting an insert fitting you should watch out for fittings with the following quality problems:

WARNING: When selecting an insert fitting you should watch out for fittings with the following quality problems:

- Mold shift (uneven wall thickness side to side)

- Cored hex nuts (these create a weak point)

- Thick ends with a cored out inside (this gives the illusion of a heavy wall fitting)

- Rough inside diameter (indicates poor casting surface finish)

- Brass vs. bronze alloy

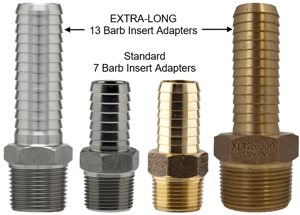

IMPORTANT: When installing a submersible pump with the use of an extra long insert fitting, a minimum of two gear clamps is recommended; three clamps can be used and is a small expense for added peace of mind.

IMPORTANT: When installing a submersible pump with the use of an extra long insert fitting, a minimum of two gear clamps is recommended; three clamps can be used and is a small expense for added peace of mind.

MAKE SURE TO USE:

- BRONZE or 304 STAINLESS adapters

- All 300 Series “87” clamps

For all down the well, buried water line applications, or any other corrosive environments, the use of brass fittings and gear clamps manufactured from 200 or 400 grades of stainless steel are not suitable!

STEP #2 - Slip the gear clamps onto the poly pipe about a foot past the end of the pipe so they are out of the way during heating (Step #3).

STEP #2 - Slip the gear clamps onto the poly pipe about a foot past the end of the pipe so they are out of the way during heating (Step #3).

STEP #3 – Heat the poly pipe by either submersing the end of the pipe (4” to 6”) in a bucket of hot water to make the pipe more pliable or use a propane torch. However, when using a flame great care must be taken to not overheat and burn the pipe. Make sure to keep moving the heat source around until the outside of the pipe starts to get shiny around the diameter and approximately 1 to 1-1/2” up the length.

STEP #3 – Heat the poly pipe by either submersing the end of the pipe (4” to 6”) in a bucket of hot water to make the pipe more pliable or use a propane torch. However, when using a flame great care must be taken to not overheat and burn the pipe. Make sure to keep moving the heat source around until the outside of the pipe starts to get shiny around the diameter and approximately 1 to 1-1/2” up the length.

STEP #4 – Immediately insert the insert adapter into the poly pipe while it is hot. Make sure to insert until the pipe is against the stop in the insert fitting. Insert fitting barbs are larger than the PE pipe inside diameter and the pipe must be expanded as the barbs are inserted. You may need to use a rubber mallet to drive it in all the way especially when using extra long insert fittings.

STEP #5A METAL INSERT FITINGS - Quickly position the gear clamps over the barbs (serrations) of the adapter before the pipe cools. Alternate the worm gear screws at 180 degrees to ensure even clamping force and maximum sealing pressure on the pipe. Torque the clamps to 60-inch pounds. When the clamps are installed while the pipe is still hot, the pliable poly will be compressed and formed into the serrations, taking on the form of the barbs. If the process takes too long, it may be necessary to reheat the pipe, so it is more pliable. Worm gear clamps, regardless of make or brand, do not have the clamping capacity to form cold poly pipe into the serrations, therefore it is critical to heat the pipe to make a fail proof, water-tight, and blow-off proof connection.

STEP #5A METAL INSERT FITINGS - Quickly position the gear clamps over the barbs (serrations) of the adapter before the pipe cools. Alternate the worm gear screws at 180 degrees to ensure even clamping force and maximum sealing pressure on the pipe. Torque the clamps to 60-inch pounds. When the clamps are installed while the pipe is still hot, the pliable poly will be compressed and formed into the serrations, taking on the form of the barbs. If the process takes too long, it may be necessary to reheat the pipe, so it is more pliable. Worm gear clamps, regardless of make or brand, do not have the clamping capacity to form cold poly pipe into the serrations, therefore it is critical to heat the pipe to make a fail proof, water-tight, and blow-off proof connection.

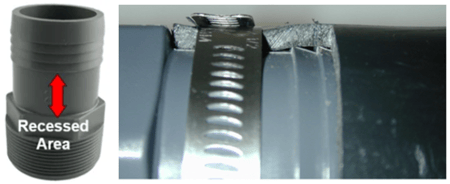

STEP #5B NYLON, POLY & PVC INSERT FITINGS - Quickly position the gear clamps in the center of the recessed section between the last insert serration (barb) this location is the best position for ensuring pull-off or blow off resistance. Normally one clamp in this position is sufficient for both a pull off resistant and water tight seal.

CRITICAL / HARD TO ACCESS LOCATIONS: For critical installations where the clamp cannot be easily accessed such as a buried water line it is best practice and highly recommended to add a second clamp over the barbs (serrations) of the adapter before the pipe cools. Alternate the worm gear screws at 180 degrees to ensure even clamping force and maximum sealing pressure on the pipe. Torque the clamps to 60-inch pounds. When the clamps are installed while the pipe is still hot, the pliable poly will be compressed and formed into the serrations, taking on the form of the barbs. If the process takes too long, it may be necessary to reheat the pipe, so it is more pliable. Worm gear clamps, regardless of make or brand, do not have the clamping capacity to form cold poly pipe into the serrations, therefore it is critical to heat the pipe to make a fail proof, water-tight, and blow-off proof connection. A clamp on the barbed section will provide greater sealing force between the pipe and the barbs, although the pull off resistance will be reduced. So clamp location is not wrong or right it depends on whether there is lateral forces at play which could pull the pipe of the insert. This is unlikely when the proper pipe preparation / warming has been followed.

If in doubt use two "GEAR" clamps the old saying that an once of prevention is worth a pound of cure could not be more relevant! For a few extra dollars on a buried or hard to access ;location the risk of a leak can be eliminated with proper procedure and two 300 Grade gear SS clamps.

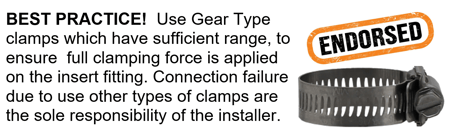

IMPORTANT: The insert fittings are designed for making a connection using "Worm Gear Clamps" which have infinite adjustment (when properly sizes for the pipe.

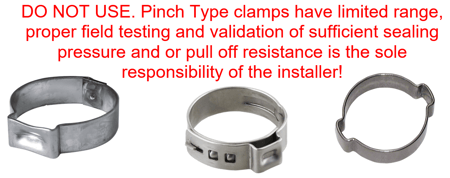

WARNING: The use of pinch type clamps is not recommended, they often result in leaking at the joint, Not because the clamp are bad, they simply cannot provide enough range to make a proper seal. The pinch type clamps can work, however it is the sole responsibility of the installer to do the required field testing to ensure the pinch clamps are providing enough sealing pressure. Boshart assumes no liability for issues resulting due to using the wrong type / size of clamp.

NOTE: When done properly using heat, the serrations and clamps will hold firmly. Testing has proven that the connections will hold securely, and that the poly pipe will be the weaker component, eventually stretching and failing due to increasing weight load.

Additional Resources.

https://support.boshart.com/barb-o.d.-dimension-for-poly-pipe-pe-insert-fittings

https://support.boshart.com/insert-fitting-pull-off-resistance-testing

https://support.boshart.com/pressure-temperature-ratings-for-bronze-insert-fittings

https://support.boshart.com/pressure-temperature-ratings-for-304-stainless-steel-insert-fittings