Why do insert fittings for poly pipe (PE) have barbs with slightly larger diameters than the I.D. of the pipe?

Why do insert fittings for poly pipe (PE) have barbs with slightly larger diameters than the I.D. of the pipe?

Poly pipe insert barbs regardless of material (zinc plated steel, brass, bronze, stainless steel, nylon, poly or PVC) are made to a larger diameter due to the semi-rigid nature of poly pipe. Standard worm gear hose clamps of any make or brand are not designed to produce the squeezing pressure that would be required to squeeze poly pipe beyond its original extruded I.D.

Therefore, the poly pipe MUST be stretched over the barb. This is often done by heating the poly pipe by dipping the end in warm water to make it more pliable.

When inserted, the poly pipe will try to retract (return-to) its extruded size like a rubber band. The worm gear hose clamps simply assist the poly pipe in returning to the original size by applying significant pressure on the poly pipe to make a water-tight seal and pull-out proof connection without difficulty.

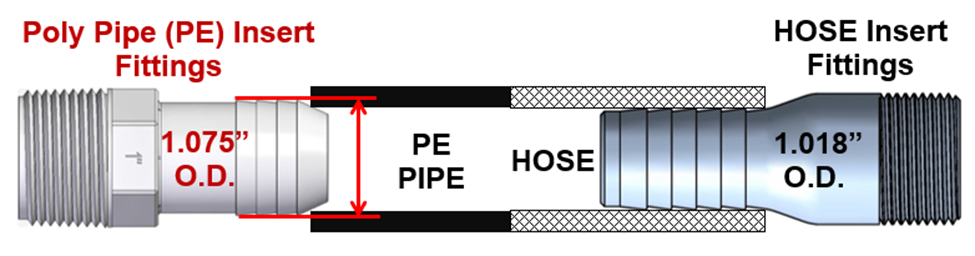

There are two notable differences between poly insert fittings and hose barb fittings.

Poly Pipe (PE) Insert Adapter (PPA-10 illustrated on the left above)

Have larger barbs or serration O.D. which stretches the pipe. The sharp 90° barb profiles bites into the poly pipe securely. When clamped it is virtually impossible to be blown off by system pressure. If properly done, the pipe will have to be cut off if removal is necessary.

Combination Nipple for Hose (GCN-100 illustrated on the right above)

Have smaller barbs or serration O.D. These will be a loose fit & will not grip in the poly pipe (PE). The smoother barb profile allows for removal and reinstallation of hose.

B.I.I. hose fittings are machined with a special flat area on the lead barb that (A) makes installation into reinforced hoses easier, and (B) allows for easy identification of a hose fitting from poly pipe insert fitting.

WARNING: The improper use of a hose barb insert fitting (combination nipple or king nipple) with poly pipe may result in a leak or catastrophic failure of the connection such as blow-off of the poly pipe!

WARNING: The improper use of a hose barb insert fitting (combination nipple or king nipple) with poly pipe may result in a leak or catastrophic failure of the connection such as blow-off of the poly pipe!

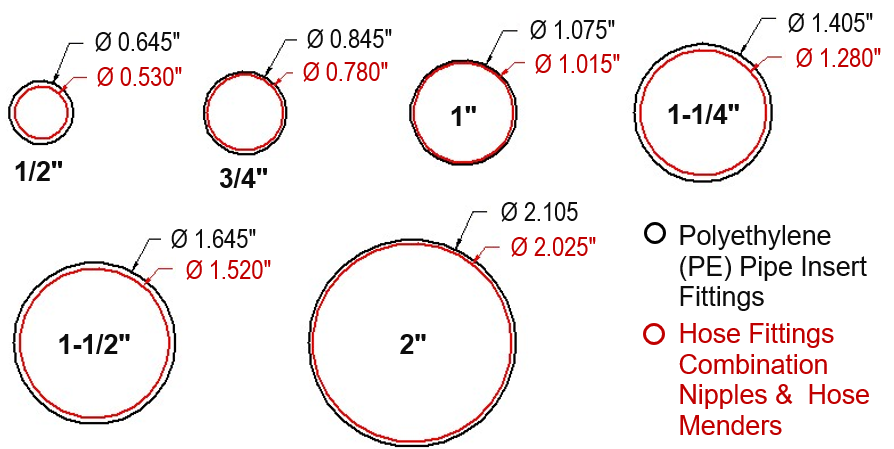

The diagram below shows the difference between the O.D. of a poly pipe insert fitting (in black) and a hose barb O.D. (in red).