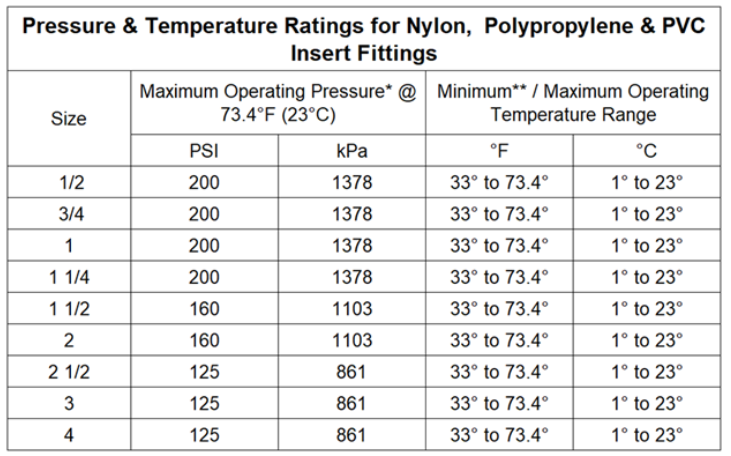

What is the Pressure & Temperature Ratings for Nylon, Polypropylene & PVC Insert Fittings?

Generally speaking, the limiting factor in a system utilizing these insert fittings is the poly pipe, and you must ensure that you verify the poly pipe maximum pressure and temperature ratings with the PE pipe manufacturer.

The chart is to be used as a guideline for the allowable Pressure & Temperature Ratings for Nylon, Polypropylene & PVC Insert Fittings.

- * Plastic insert fittings are intended for cold water applications, including irrigation, well service, and potable water applications. For operating pressures over the stated Max. PSI and / or temperatures over 73.4°F (23°C) the use of metal insert fittings is highly

- ** Fittings MUST be protected from freezing temperatures where fluid expansion due to freezing could occur.

#1 - If this product is used outside the intended cold-water applications and / or at temperatures over the stated operating temperature rating it is solely the user's responsibility to determine the suitability of the fitting / fitting material for the intended service

#2 - This product is not to be used with compressed gases.

Note:

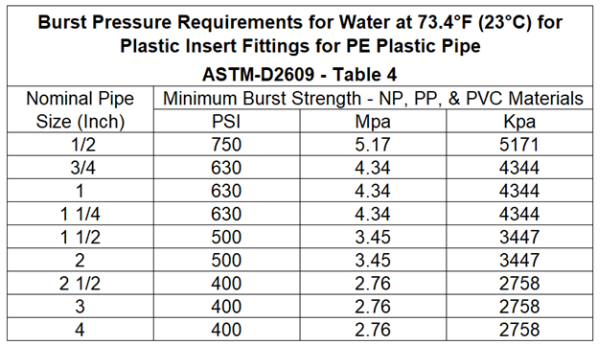

Plastic Insert fittings are not manufactured to a pipe schedule such as SCH. 40 or SCH. 80 like PVC pipe and pipe fittings are. They are manufactured to the ASTM-D2609 standard and meet or exceed the standard burst test requirements as per Table 4 in ASTM-D2609. These burst tests are the basis for the maximum pressure and temperatures recommended in the chart above. These ratings provide a safety factor to ensure the fittings are not subjected to too high of an operating pressure or temperature.