What are the PROS and CONS of Plain, Conduit, and Watertight Well Caps?

In this article we will go over the PROS and CONS of each type of well cap. The use of plain or conduit caps is on a steady decline due to their lack of protection for your well system. This combined with updates to the most recent well construction codes and regulations, mean they no longer meet the applicable codes, and are not allowed for use in the vast majority of the USA and Canada. Well codes have increased mandates that well caps must be of a sanitary design. This means they must be watertight, vermin-proof, and of a locking or tamper proof design.

|

PROS |

CONS |

|

Least expensive option for submersible pump installations |

Not allowed in many well construction codes |

|

Can be used for jet pump installations which utilize Pitless Adapters (if permitted by the applicable well construction codes) |

Unsanitary and not vermin-proof |

Why are Plain and Conduit well caps considered unsanitary?

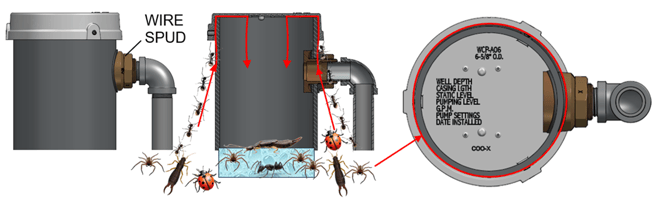

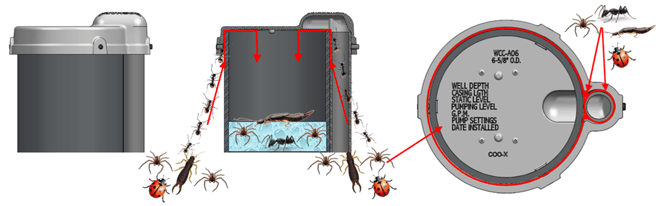

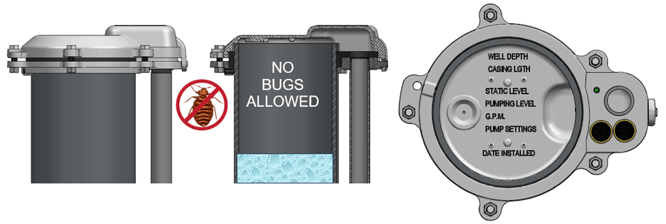

Regardless of the make or brand, all one piece Plain or Conduit caps will have a small, open, annular space between the inside of the well cap and the well casing. This open space is required to allow the well to breathe. When the pump starts and is drawing down the water level, air must be able to enter the well. When the pump stops the air must be allowed to escape for the water inside the well to raise and recover to the normal static level before the next pumping cycle.

Unfortunately, with plain or conduit well caps this rapid air movement into the well will suck in any bugs that have decided to hang out in the gap between the well casing and the well cap. Given the nature of spiders, earwigs, lady bugs, ants, and the list goes on, they like to hide out in the safe place these well caps provide by protecting them from the elements. They are unaware of their pending peril until the moment they get sucked into the well for a short lived pool party, before they decay and are eventually pumped into the homes water storge tanks for your drinking water pleasure.

|

PROS |

CONS |

|

Least expensive option for submersible pump installations |

Not allowed in many well construction codes |

|

Can be used for jet pump installations which utilize Pitless Adapters (if permitted by the applicable well construction codes) |

Unsanitary and not vermin-proof |

|

PROS |

And More PROS |

|

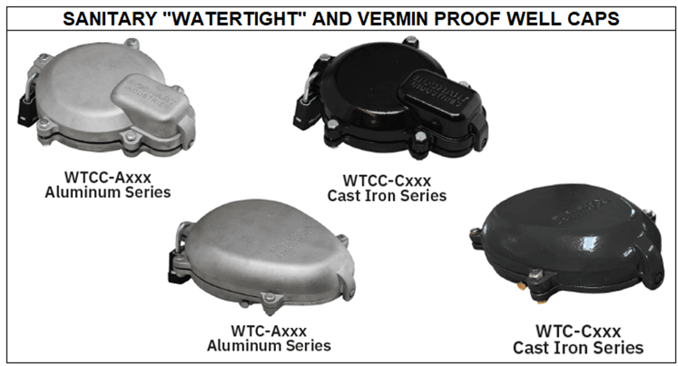

Great value given the many benefits |

Watertight certified as per ASSE Standard #1093-2019(R2023) / WSC PAS-97(2019)(R2023) - Section 3.7 Water-Resistant Capability for Sanitary Well Caps |

|

Bug and vermin-proof as per ASSE Standard #1093-2019(R2023) / WSC PAS-97 (2019)(R2023) - Section 3.6 Vermin and Contaminant / Pollutant Resistance and Venting of Sanitary Well Caps |

Tamper Proof as per ASSE Standard #1093-2019(R2023) - WSC PAS-97 (2019)(R2023) - Section 3.5 Tamper Resistance for Sanitary Well Caps |

|

BOSHART well caps meet all the applicable requirements of well construction codes. Many brands do not meet the venting and tamper proof requirements - Buyer beware! |

Ideal for submersible pump installation permitted by the applicable well construction codes |

|

Models with 1" or 1-1/4" FPR conduit connections are available for easier installation of larger diameter electrical submersible pump cables |

CON? - Costs more than plain or conduit caps. However, the protection it provides for your well water makes it worth every penny! |

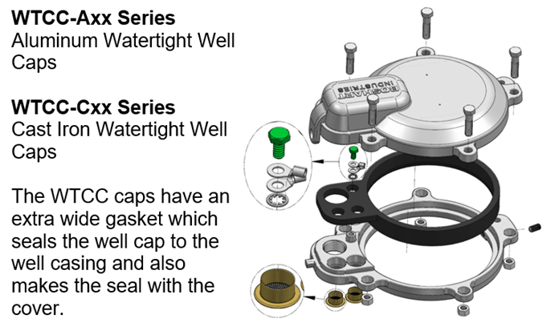

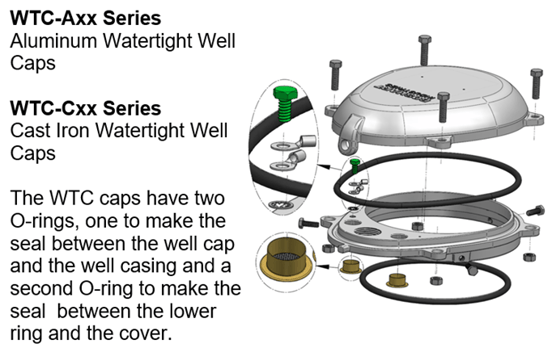

The two diagrams below illustrate the difference in construction between the WTCC-A / WTCC-C, that has an extra wide gasket seal, versus the WTC-A / WTC-C series well caps, which utilize a double O-ring sealing system.

Additional Resources:

https://support.boshart.com/what-is-the-function-of-well-caps-in-a-well-water-system

https://support.boshart.com/how-do-i-identify-a-well-cap-model-number-for-replacement-parts

https://support.boshart.com/what-is-the-function-of-each-well-water-pressure-system-component

https://support.boshart.com/what-is-new-with-our-well-cap-product-line

https://support.boshart.com/four-reasons-the-wtcc-a-or-wtcc-c-watertight-well-caps-are-the-1-choice

https://support.boshart.com/how-do-i-install-a-wtcc-series-well-cap

https://support.boshart.com/how-do-i-install-a-wtc-series-well-cap

https://www.watersystemscouncil.org/resources/well-standards/