Four Reasons the WTCC-A or WTCC-C Watertight Well Caps are the #1 Choice

In this article we will first do a quick review of the types of well caps that are available. We will conclude with 4 reasons why the WTCC series have become the go to well cap.

In this article we will first do a quick review of the types of well caps that are available. We will conclude with 4 reasons why the WTCC series have become the go to well cap.

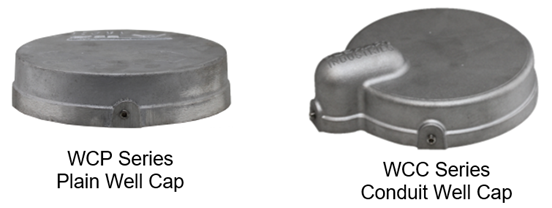

Let’s get started by talking about plain and conduit well caps. Their use is steadily declining due to updates to most well construction codes and regulations. They no longer meet the applicable well construction codes in many jurisdictions due to the lack of protection they provide for your well water.

Well construction codes in most areas are mandating that well caps be of a sanitary design meaning they are watertight, vermin-proof, and of a locking or tamper proof design.

Well construction codes in most areas are mandating that well caps be of a sanitary design meaning they are watertight, vermin-proof, and of a locking or tamper proof design.

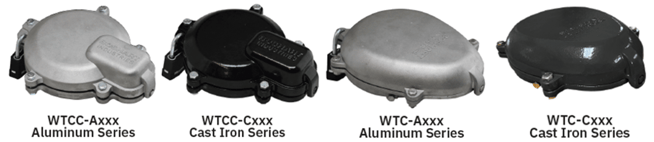

Both the BOSHART WTCC and WTC designs are great choices. These watertight well caps meet and exceed all the applicable requirements of well construction codes. They are third party certified to the ASSE Standard #1093-2019(R2023) / WSC PAS-97 (R2023). Models with a 1" FPT or a 1-1/4" FPT conduit connection are available for easier installation of larger diameter electrical submersible pump cables.

- Watertight certified as per ASSE Standard #1093-2019(R2023) / WSC PAS-97 (R2023) - Section 3.7 Water-Resistant Capability for Sanitary Well Caps

- Bug and Vermin-proof as per ASSE Standard #1093-2019(R2023) / WSC PAS-97 (R2023) -Section 3.6 Vermin and Contaminant/Pollutant Resistance and Venting of Sanitary Well Caps

- Tamper Proof as per ASSE Standard #1093-2019 (R2023) / WSC PAS-97 (R2023) - Section 3.5 Tamper Resistance for Sanitary Well Caps

CAUTION: Many brands of water-tight well caps do not meet the venting or tamper proof requirements.

The Difference!

The Difference!

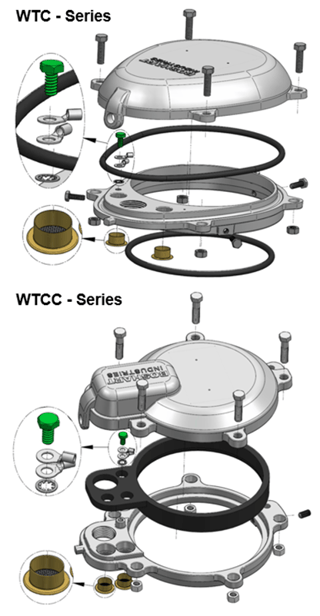

The diagrams to the right illustrate the difference in construction between Boshart’s two designs of watertight well caps. The WTCC-A / WTCC-C series has an extra wide gasket seal versus the WTC-A / WTC-C series which utilizes a double O-ring sealing system.

WTC-Axx Series Aluminum / WTC-Cxx Series Cast Iron Watertight Well Caps:

The WTC caps use two O-rings, one to make the seal between the well cap and the well casing and a second O-ring to make the seal between the lower ring and the cover.

WTCC-Axx Series Aluminum / WTCC-Cxx Series Cast Iron Watertight Well Caps:

The WTCC caps have an extra wide gasket which seals the well cap to the well casing and also makes the seal with the cover.

Benefits of the WTCC Series

Below are four reasons why the WTCC design is so widely accepted and gaining in popularity over well caps that have a double O-ring sealing system.

#1 – They are easier and faster to install.

There is no need to remove the five bolts and top cover to install the WTCC well cap. This is very beneficial to the well driller since in many cases the well head must be sealed off after drilling and the submersible pump is often installed later. Simply loosen off the bolts and push it down onto the well casing until it contacts the internal positioning stop, then tighten the bolts and set screw… Done!

NOTE: The double O-ring well cap system requires that the cover be removed in order to install the lower ring assembly.

#2 – Less risk of dropping or losing the hardware.

Since the cover does not need to be removed to install the WTCC cap onto the well casing, the risk of dropping bolts and nuts into the mud or snow is greatly reduced.

NOTE: Unlike the double O-ring well cap system, the cover does not need to be removed until the submersible pump is installed. This is most often at a later date, after the Pitless Adapter is installed and the open pit is backfilled.

#3 – Easy to achieve a positive seal to the well casing.

The deeper sealing pocket with an extra wide gasket is very forgiving and provides a greater sealing area. This is a huge benefit if a well casing is not cut off as straight and perpendicular as it should be.

NOTE: For WTC cap installation, the well casing must be cut straight and perpendicular since the O-rings contact much less area on the casing. This requires that the installer take greater care when cutting off the casing. The degree of accuracy required is much greater than required for the WTCC series caps which have a 1” wide sealing gasket.

#4 – Aluminum & More Sizes Available.

With the addition of the aluminum WTCC-A series, there are also additional sizes being introduced in the WTCC series. The interest in these well caps has been renewed by installers who like to use the aluminum well cap which were previously not available in the wide gasket design.

Conclusion:

Both the WTCC-A / WTCC-C series (wide gasket seal) or the WTC-A / WTC-C series (double O-ring seal) provide excellent well head protection, and function very well. In the end it comes down to the installers’ preference and what they are accustomed to using. There is no wrong decision to be made!

Hopefully this information has provided you with additional insights on the difference and why you may want to choose one model over the other.

Additional Resources:

https://support.boshart.com/what-is-the-function-of-well-caps-in-a-well-water-system

https://support.boshart.com/what-are-the-pros-and-cons-of-plain-conduit-and-watertight-well-caps

https://support.boshart.com/how-do-i-identify-a-well-cap-model-number-for-replacement-parts

https://support.boshart.com/what-is-the-function-of-each-well-water-pressure-system-component

https://support.boshart.com/what-is-new-with-our-well-cap-product-line

https://support.boshart.com/how-do-i-install-a-wtcc-series-well-cap

https://support.boshart.com/how-do-i-install-a-wtc-series-well-cap

https://www.watersystemscouncil.org/resources/well-standards/