What is the function of well caps in a well water system?

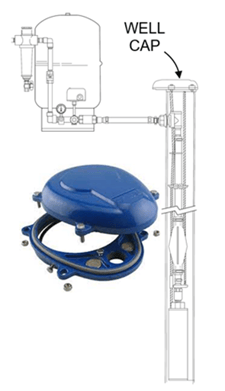

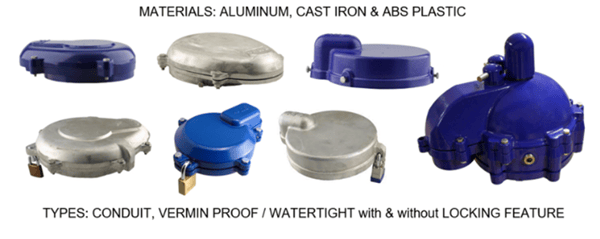

Boshart's well caps are designed to go over the top of a well casing. They provide a cover for the well to prevent debris from entering. They come in two basic types: a basic one-piece conduit cap, and in vermin proof, watertight, and tamper-proof designs which are two- or three-piece designs. Boshart recommends that at minimum, a vermin proof design be used to ensure that bugs and small vermin cannot enter the well. Most codes now mandate that a vermin proof cap with screened vents be used. When the conduit cap or the cover of a vermin proof well cap is removed, the installer has clear access to the well, allowing you to keep all the wiring attached. The bottom, lower ring slides down over the well casing providing a watertight and vermin proof seal to the casing. This is achieved by compressing either a gasket or an O-ring between the casing and the lower ring. The lower ring is then secured into position by means of set screws. When ordering, it is critical to know the outside diameter of the well casing to determine the proper size well cap. To ensure you order the correct size well cap, you must measure across the top of the casing, through the center line, from outside edge to outside edge, to determine the maximum distance across the top of the casing.

Boshart's well caps are designed to go over the top of a well casing. They provide a cover for the well to prevent debris from entering. They come in two basic types: a basic one-piece conduit cap, and in vermin proof, watertight, and tamper-proof designs which are two- or three-piece designs. Boshart recommends that at minimum, a vermin proof design be used to ensure that bugs and small vermin cannot enter the well. Most codes now mandate that a vermin proof cap with screened vents be used. When the conduit cap or the cover of a vermin proof well cap is removed, the installer has clear access to the well, allowing you to keep all the wiring attached. The bottom, lower ring slides down over the well casing providing a watertight and vermin proof seal to the casing. This is achieved by compressing either a gasket or an O-ring between the casing and the lower ring. The lower ring is then secured into position by means of set screws. When ordering, it is critical to know the outside diameter of the well casing to determine the proper size well cap. To ensure you order the correct size well cap, you must measure across the top of the casing, through the center line, from outside edge to outside edge, to determine the maximum distance across the top of the casing.

For more information, please refer to the ‘Pump & Well Accessories’ document that can be found in the additional training and reference materials.

In summary, the function of well caps in a well water system is to:

- Go over the top of the well casing

- Prevent debris from entering the well

- Ensure that bugs and small vermin cannot enter the well

ADDITIONAL RESOURCES:

https://support.boshart.com/what-is-the-function-of-each-well-water-pressure-system-component

https://support.boshart.com/how-do-i-install-a-wtcc-series-well-cap

https://support.boshart.com/how-do-i-install-a-wtc-series-water-tight-well-cap

https://support.boshart.com/how-do-i-identify-a-well-cap-model-number-for-replacement-parts