What 10 features make the Boshart PS02 series pressure switch the best choice?

10 Notable Features of the Boshart PS02 Series Pressure Switches:

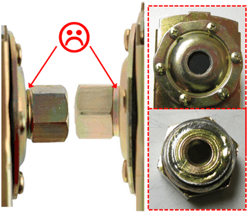

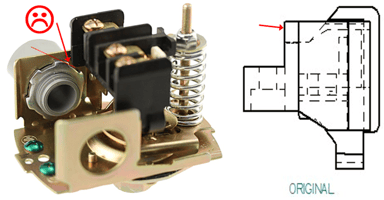

#1 Super Strong Back Plate Connection

Original (Standard on Import Switches)

The threaded connections are friction welded into the flange. It is reported that there have been wide spread failures due to the welds failing causing significant property damage.

B.I.I. “CUSTOM” Design

B.I.I. “CUSTOM” Design

The BII back plates are custom made using a process which welds the hex connection to the metal flange around the perimeter of the hex. This results in a connection that is 250% stronger than the connection on other import brands.

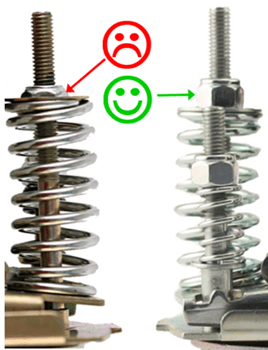

#2 Superior Electro Plating

Original (Standard on Import Switches)

Original (Standard on Import Switches)

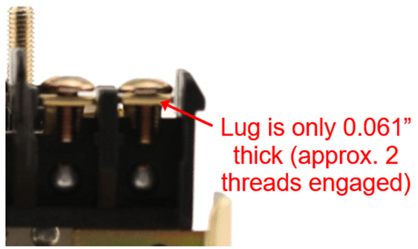

The plating used on the majority of import switches is a “Hexavalent” Chromium (Chromium IV).

This type of plating is banned in North America and Mexico due to its harmful effects on the environment and potentially serious health effects on plating factory workers. Most importers opt to buy the cheaper product despite the known environmental issues.

B.I.I. “CUSTOM” Plating

B.I.I. “CUSTOM” Plating

Boshart has taken the high road switching to a “Trivalent” Chromium (Chromium III) plating in 2010 when learning about the issues with Chromium IV. We pay a premium to use this more expensive, eco-friendly plating as is the responsible thing to do. The added bonus is that salt spray testing has proven this plating provides much greater corrosion resistance! So, the premium is well worth the money.

This plating is an RoHS approved plating that is NOT harmful to the environment or the plating factory workers.

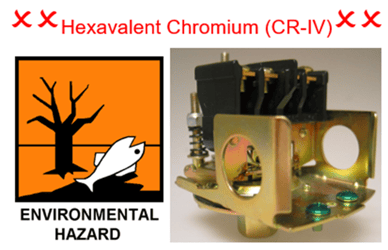

#3 Greater Thread Engagement for Terminal Screws

Original (Standard on Import Switches)

Original (Standard on Import Switches)

The terminal screw lugs are drilled leaving minimum thread engagement for the terminal screws. This results in a significant number of stripped threads reducing the switch to scrap metal and costing the installer a great deal of time.

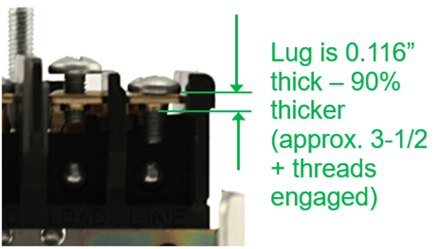

BII “CUSTOM” Design

The terminal screw lugs are punched in a die that forms the metal into a funnel shape. This allows for almost double the thread engagement for the terminal screws. We have had zero reports of stripped threads with this improved design.

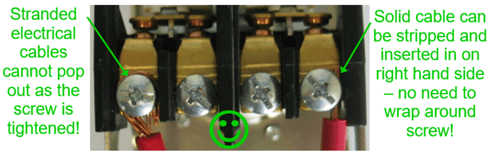

#4 Longer Terminal Screws

Original (Standard on Import Switches)

Typical import switches have quite short terminal screws. This results in a problem with the screws being accidentally turned right out when loosening the screw to insert the pump cable wire under the terminal screw head (especially on larger gauge wires #10 AWG or heavier). This is frustrating and often results in the loss of the screw.

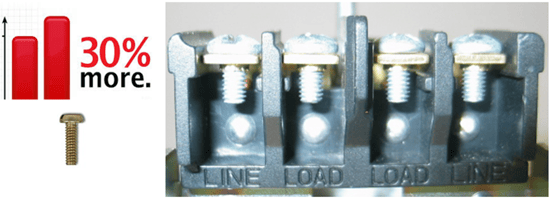

BII “CUSTOM” Design

BII terminal screws were lengthened by 30%+ to reduce the chance of the screws being turned out accidently when loosening the screw. The ability to raise the terminal screw head higher makes the insertion of the pump cable wire under the terminal screw head much easier on larger gauge wires.

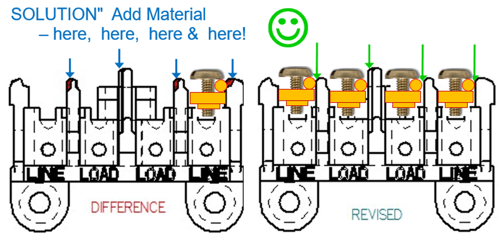

#5 Terminal Block Design Retains Wires

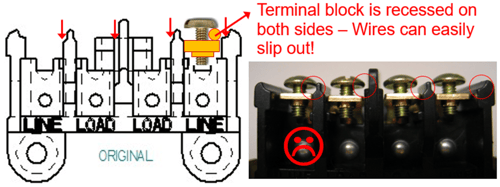

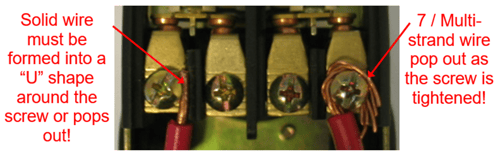

Original (Standard on Import Switches)

On standard switches, the terminal block is recessed on both sides, this allows wires to easily slip out!

On typical import pressure switches, the terminal block divider is cupped away from the terminal screw on both sides.

BII “CUSTOM” Design

BII terminal block dividers are straight up on the right hand side of each terminal screw. This ensures the wire is securely trapped and cannot pop out!

BII terminal block dividers are only cupped away from the terminal screw on the left hand side.

#6 Terminal Block Design Provides Greater Clearance for Conduit Fittings

Original (Standard on Import Switches)

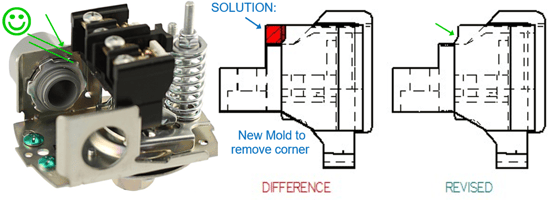

On standard switches, the corner of the terminal block hits the conduit fitting lock nut!

BII “CUSTOM” Design

On BII designs, the corner is removed - problem solved!

BII terminal blocks give ample clearance around the conduit openings, making it easy to install all types of conduit fitting jam nuts without hitting the terminal block.

#7 Fail Proof Cover Cap Nut System

Original (Standard on Import Switches)

Original (Standard on Import Switches)

Typical import switches have the cap nut press fit into the cover. The system is poor, minimal pressure will pop them loose, and the cap nuts are often lost.

BII “CUSTOM” Design

BII “CUSTOM” Design

BII cap nuts are machined with a groove. A mechanical internal tooth retainer ring is press fit over the cap nut securely fastening the cap nut into the cover.

#8 Raised Adjustment Nut for Easy Pressure Setting

Original (Standard on Import Switches)

The adjustment nut is recessed into the cupped washer. This makes it very difficult to adjust with a wrench or nut driver as the socket easily slips on the rounded edges of the lock nut and this is frustrating to the contractor.

BII “CUSTOM” Design

The BII switch assembly was upgraded to include a spacer to raise the adjustment nut up out of the recessed cup washer.

This small but important modification has eliminated the slippage issue, as the nut driver now can be put right down on the entire lock nut, making it very easy to adjust with a nut driver.

#9 Covers Verify No-Lead Certification

Original (Standard on Import Switches)

Many import switches are not certified to ensure compliance with the reduced lead content requirements of <0.25% Pb as defined in the 2014 S.D.W.A. Also, typically those that are certified do not have any markings on the cover that makes NL identification easy for the inspectors.

BII “CUSTOM” Design

The new BII cover tooling that incorporates the NL certification logo is much larger. It is 1- 3/4” wide x 2-1/8” high, which allows for greater flexibility in the option for private labeling the switch covers. Boshart also makes identification easy between the AUTO-OFF and LOW-PRESSURE CUT-OUT switches that both have the lever and appear to be identical.

3/4” wide x 2-1/8” high, which allows for greater flexibility in the option for private labeling the switch covers. Boshart also makes identification easy between the AUTO-OFF and LOW-PRESSURE CUT-OUT switches that both have the lever and appear to be identical.

#10 Large Interchangeable Name Plate for Private Labeling

Original (Standard on Import Switches)

Typically, the area for logo imprinting is very small and makes private labelling difficult, due to the limited space and shape of the plate.

BII “CUSTOM” Design

The new BII cover tooling that incorporates the NL certification logo is much larger 1-3/4” wide x 2-1/8” high which allows for greater flexibility in the option for private labeling the switch covers.

Our attractive, high quality packaging & friendly customer service are simply added bonuses.

Our attractive, high quality packaging & friendly customer service are simply added bonuses.

BII packaging contains the following information:

- Electrical Ratings

- Pressure Ranges

- Temperature Ratings

- Certifications / Approvals

- Application / Features Information

- Installation Instructions

- Pressure Setting Instructions

Cross Reference

The information contained in this presentation is generalized based on typical findings for other import brands. In no way is it implying that all competitors' switches will be the same. In-fact we have seen some brands mirror some of the BII upgrades. However, many of the key added benefits will only be found on the BII “CUSTOM” made switch.

The information contained in this presentation is generalized based on typical findings for other import brands. In no way is it implying that all competitors' switches will be the same. In-fact we have seen some brands mirror some of the BII upgrades. However, many of the key added benefits will only be found on the BII “CUSTOM” made switch.

After all, you may not be buying a pressure switch at all… but peace of mind!

After all, you may not be buying a pressure switch at all… but peace of mind!

Not all switches are created equal! As a buyer it is important to know what value-added features the product has. Boshart Industries realizes that there are cheaper models on the market, and we strongly believe the small difference in price is well worth the peace of mind as we strive to provide high value, user friendly, & trouble-free products!

Additional Resources:

https://support.boshart.com/what-information-is-needed-to-properly-select-a-pressure-switch

https://support.boshart.com/what-is-meant-by-cut-in-and-cut-out-settings

https://support.boshart.com/what-is-meant-by-cut-in-and-cut-out-settings

https://support.boshart.com/how-do-i-adjust-a-pressure-switch

https://support.boshart.com/what-are-the-adjustment-ranges-for-a-ps02-series-pressure-switch

https://support.boshart.com/i-have-totally-messed-up-my-pressure-switch-settings-now-what

https://support.boshart.com/what-is-a-pressure-switch-with-low-pressure-cut-off-feature

https://support.boshart.com/why-is-my-low-pressure-cut-out-switch-nuisance-tripping

https://support.boshart.com/do-you-carry-loss-of-prime-pressure-switches

https://support.boshart.com/what-are-the-applications-for-an-auto-off-pressure-switch