What is the difference between CW and ERW welded pipe vs Seamless Pipe?

What is the difference between CW and ERW welded pipe?

![]()

Welded Pipe

Welded Pipe

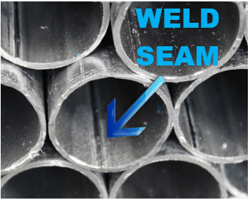

In this article we will discuss the more common types and processes involved in welding steel pipes. Welded pipes are produced mainly by two distinct manufacturing methods, continuous weld (CW) or electric resistance weld (ERW). Both methods are referred to as “welded” steel pipe.

The other type of pipe you will often hear about is “seamless pipe,” which we will cover briefly at the end of this article.

Continuous Welded Pipe

Continuous welded (CW) pipe is made of steel plate or steel strip after crimping, generally to a fixed length of 6 meters. The welding pipe production process is simple, has high production efficiency, can meet a variety of specifications, and involves less equipment investment. Generally, however, welded pipe has less strength than that of seamless pipe.

The CW process is the most cost-effective manufacturing method for producing steel pipe. The CW process is used to produce smaller diameter sizes from NPS 1/8” to NPS 4”. CW pipe is primarily utilized for supply of water and gas. Continuous welded pipes are considered as the lowest cost variants among all steel pipe types and are widely used in plumbing and structural applications.

Electric Resistance Welded Pipe (ERW)

Electric resistance welded (ERW) pipe is manufactured by cold forming a sheet of steel into a cylindrical shape. Current is then passed between the two edges of the steel to heat the steel to a point at which the edges are forced together to form a bond without the use of welding filler material. Electric resistance weld pipe is normally produced in sizes from NPS 2” thru NPS 24.”

ERW is made using a high frequency weld (HFW) process. The high frequency process is used to manufacture pipe for use in new pipeline construction. NOTE: In the past ERW pipe was also made using a low frequency welded (LFW) process. Overtime, the welds of low frequency ERW pipe was found to be susceptible to selective seam corrosion, hook cracks, and inadequate bonding of the seams. Therefore, low frequency welding is no longer used to manufacture ERW pipe.

The links below provide a chart with a MAXIMUM WORKING PRESSURE GUIDE for:

BLN & GN Series Sch. 40 Pipe Nipples and BLRCP & GRCP Series Ready Cut Pipe - ASTM A53 Grade B Carbon Steel ERW Welded Threaded Pipe.

BLN & GN Series Sch. 40 Pipe Nipples and BLRCP & GRCP Series Ready Cut Pipe - ASTM A53 Grade B Carbon Steel ERW Welded Threaded Pipe.

https://support.boshart.com/what-is-the-maximum-working-pressure-for-steel-pipe-nipples

GHN Series Sch. 80 Galvanized Pipe Nipples - ASTM A53 Grade B Carbon Steel ERW Welded Threaded Pipe Nipples.

NOTE: The BLHN Series Sch. 80 Black Pipe Nipples are manufactured from ASTM A106 Seamless Carbon Steel Pipe for High-Temperature Service. (Scroll Down)

SS304N Series Nipples SS304RCP Series Ready Cut Pipe - ASTM A312 Grade 304 Stainless Steel Welded Threaded Pipe.

SS304N Series Nipples SS304RCP Series Ready Cut Pipe - ASTM A312 Grade 304 Stainless Steel Welded Threaded Pipe.

https://support.boshart.com/what-is-the-maximum-pressure-rating-for-304-ss-pipe-nipples

SS316N Series Nipples SS316RCP Series Ready Cut Pipe - ASTM A312 Grade 316 Stainless Steel Welded Threaded Pipe.

SS316N Series Nipples SS316RCP Series Ready Cut Pipe - ASTM A312 Grade 316 Stainless Steel Welded Threaded Pipe.

https://support.boshart.com/what-is-the-maximum-working-pressure-for-316-ss-pipe-nipples

Seamless Pipe

Seamless Pipe

The name indicates the difference in the basic manufacturing method. Seamless pipe is extruded or drawn from a billet, whereas welded pipe is formed from a strip of sheet metal that is rolled to form a cylindrical shape and the seam is then welded to produce a tube. Welded pipe is considerably less expensive to manufacture than seamless.

Why use seamless pipe?

The working pressure of welded pipe is approximately 20% less than for a seamless pipe. Working pressure can be a determining factor when selecting seamless pipe over welded pipe. However, seamless pipe is most often selected since the process reduces the potential of impurities. Impurities reduce the corrosion resistance. The weld area is considered to be inhomogeneous (meaning non-uniform or varied) consequently exhibiting different malleability, lower levels of corrosion resistance, and a wider range of dimensional variation. Drawing welded pipe reduces these anomalies and therefore, is often the reason behind why seamless pipe is specified.

Brass pipes are not welded. All brass piping is formed by the extrusion method, a process of pressing billets of hot liquified brass through a forming die having a precisely sized and shaped opening, forming a long hollow tube.

BRN Series Nipples, BRNRCP Ready cut Pipe - ASTM B43 Red Brass Seamless Threaded Pipe Nipples.

BRN Series Nipples, BRNRCP Ready cut Pipe - ASTM B43 Red Brass Seamless Threaded Pipe Nipples.

https://support.boshart.com/what-is-the-maximum-working-pressure-for-red-brass-pipe-nipples

BLHN Series Schedule 80 Black Steel Nipples - ASTM A106 Seamless Carbon Steel Pipe for High-Temperature Service.

https://support.boshart.com/what-is-the-maximum-working-pressure-for-steel-pipe-nipples