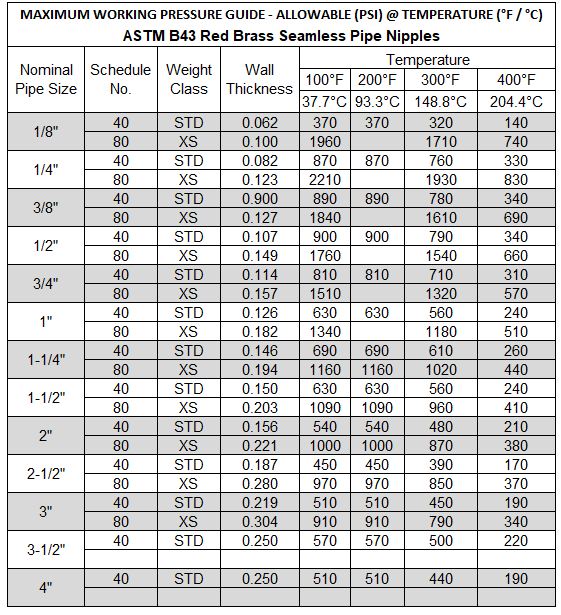

What is the maximum working pressure for Red Brass pipe nipples?

What is the maximum working pressure for Red Brass pipe nipples?

FOR REFERENCE ONLY ! This information is a reference guide only. Specifying the correct pipe schedule and pressure class of fitting depends on many factors. It is the ultimate responsibility of the end user's piping engineer to specify the correct pipe schedule and pressure class of fitting which will meet the maximum operating pressures / temperatures of the system for safe operation in the intended application.

NOTES:

1) All working pressures are Non-Shock.

2) Considerations were taken into account for the wall thickness material removed by threading. No allowances were made for corrosion, erosion, mechanical loads, and/or bending moments.

3) If temperatures and or working pressures higher than listed can be anticipated, consult the end user's piping engineer.