What is the benefit of a 7/8” diameter plunger in the YHBR and YHSS yard hydrant?

What is the benefit of a 7/8” diameter plunger in the YHBR and YHSS yard hydrant?

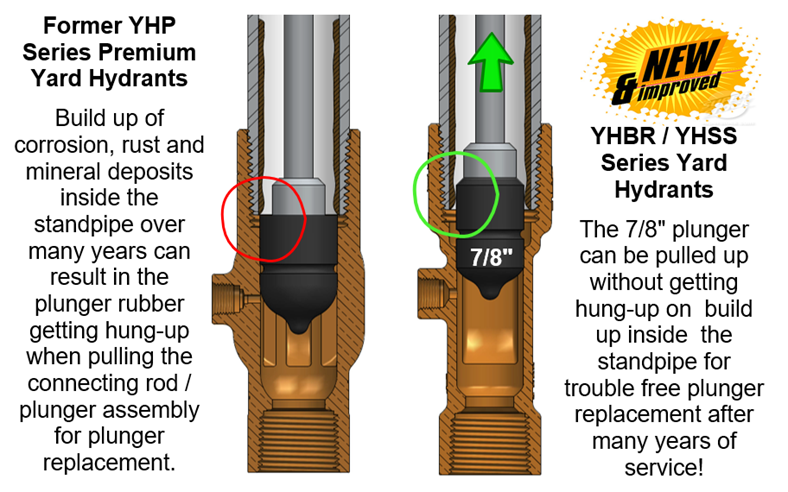

The benefit of the smaller 7/8” diameter plunger in the YHBR and YHSS yard hydrant is that it is easier to change out after many years of service when a hydrant is installed in conditions that result in a buildup of corrosion, rust/Iron, scale, or mineral deposits on the inside wall of the standpipe.

The benefit of the smaller 7/8” diameter plunger in the YHBR and YHSS yard hydrant is that it is easier to change out after many years of service when a hydrant is installed in conditions that result in a buildup of corrosion, rust/Iron, scale, or mineral deposits on the inside wall of the standpipe.

Where water quality is good this is not a problem, and hydrant plungers can be pulled after 20 plus years without any issues, however in some areas the resting build up can happen over 10 – 15 years (maybe earlier in poor water conditions where a yard hydrant with a galvanized standpipe was used)

The change was to the smaller plunger diameter was made with the goal of eliminating this problem so that plunger repair replacement easier / trouble free even after 20-30-40 years of service in poor conditions.

The diagram below illustrates how the plunger can be pulled up without any interference even with some build up inside the standpipe.

The selection of a YHSS Series Stainless Steel yard hydrant will further reduce the chance of corrosion / build up inside the standpipe, a wise choice in any yard hydrant installation for increased longevity. In areas where buildup of corrosion, rust / iron, scale, or mineral deposits on the inside wall of the standpipe over 5-10-20-40 years is expected the selection of a YHSS series 304 SS hydrant is a great decision.

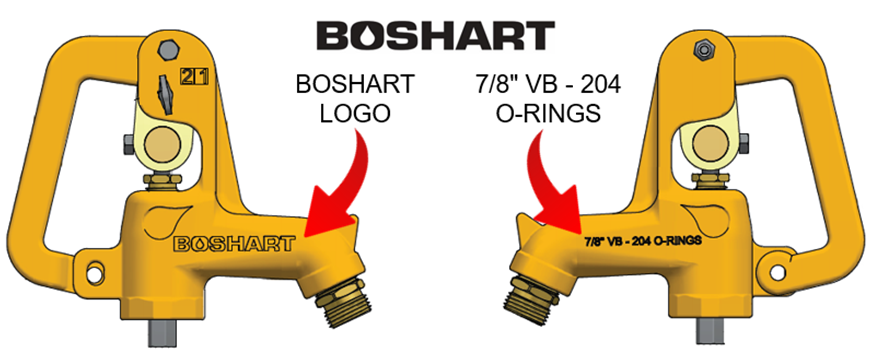

The new hydrants require a 7/8” plunger repair kit – Part No.13YHRK-BOSHART

The head castings are clearly marked to indicate that the hydrant has the 7/8” Valve body, the BOSHART logo and the gold color all help with identification for repair parts when required.

Additional Resources:

https://support.boshart.com/how-do-i-install-a-boshart-yhss-series-yard-hydrant-1

https://support.boshart.com/how-do-i-install-a-boshart-yhbr-series-yard-hydrant

https://support.boshart.com/how-to-adjust-or-repair-a-boshart-yhbr-or-yhss-series-yard-hydrant