What are 10 improvements and 10 great features that remain the same on the BOSHART yard hydrant?

*The new YHBR and YHSS series hydrants are not available until October 2023.

The following new and improved features do not apply to the former yard hydrant models YHP-XX, YHP-XXNL, YHPCR-XX, YHPCR-XXNL, YHPCRS-XXNL, YHPHC-XX, YHPHC-XXNL, YHPHCCR-XX, YHPHCCR-NNNL, YHS-XXNL, PEYH-0XX, PENL-YH07-XX, and PENL-YH07SS-XX

What are 10 improvements on the BOSHART yard hydrant?

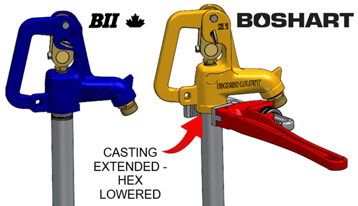

HEAD CASTING – CHANGE # 1

The head casting was made longer to extend the hex below the locking pad. This makes it easier to grip the head casting in any position for servicing when plunger replacement is required.

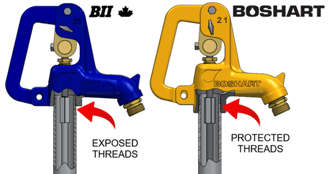

HEAD CASTING - CHANGE # 2

HEAD CASTING - CHANGE # 2

The extension of the casting also allows for custom machining of a deeper thread. The head casting encases the entire standpipe thread so that no bare threads are left exposed to the elements. This eliminates rusting and corrosion and makes for a more robust joint.

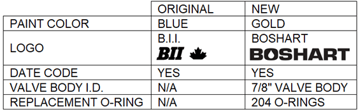

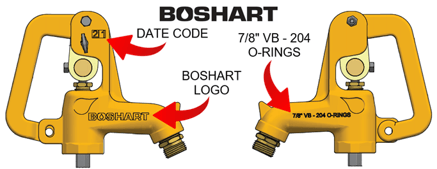

HEAD CASTING - CHANGE # 3

The head casting color and markings have been changed to easily identify the new BOSHART 7/8” plunger yard hydrant from the original BII 1” plunger version. You will notice the following changes:

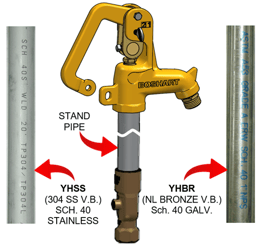

VALVE BODY CASTING - CHANGE # 4

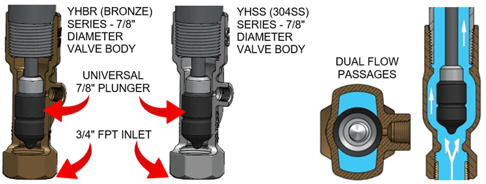

All the valve bodies now incorporate two large flow channels and are available in both NL BRONZE and 304SS (NEW!). The valve bodies are made for a 7/8” plunger, but the port size remains the same as the YHP series. The leaded bronze and high capacity valve bodies have been discontinued since the flow rates of the new valve bodies provide more flow capacity than required. The new YHSS series hydrants will be assembled using a SS valve body, standpipe, long connecting rod, hex coupling, and polished operating rod. This unit will be an excellent choice for areas where the soil or water is highly aggressive.

VALVE BODY CASTING - CHANGE # 5

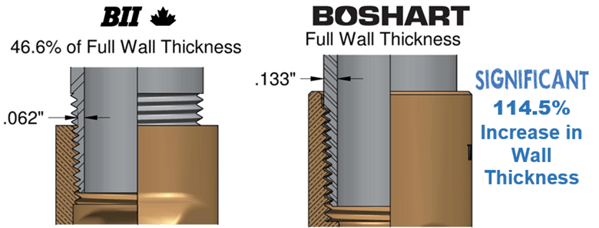

The buried valve body to standpipe connection has no exposed standpipe threads. Generally, yard hydrants engage 3-1/2 to 5 threads into the valve body leaving the remaining threads exposed to the soil. This means the thin wall cross-section of standpipe is subjected to accelerated corrosion. All BOSHART yard hydrants now have precision machined valve bodies to engage the full thread length into the valve body leaving only the full wall section of standpipe exposed to the soil.

VALVE BODY CASTING - CHANGE # 6

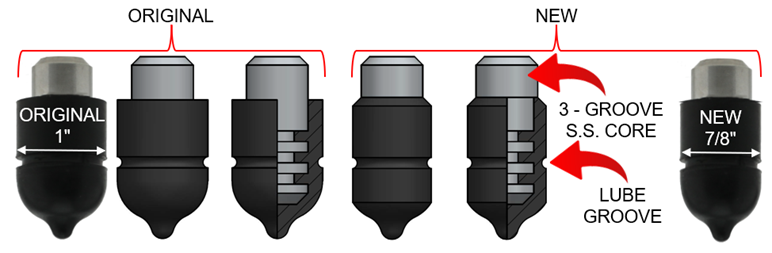

The valve bodies have been changed to incorporate a 7/8” diameter plunger which will be universal in both the YHBR NL BRONZE and YHSS 304SS valve bodies. The change has been made to make a great product excellent!

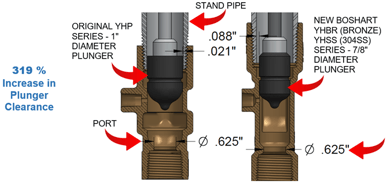

Why the change? Over the past 20 years of producing the premium yard hydrant, we have actively listened to our customers. In recent years, we have had some reports with regards to hydrants that have been in service for many years (15 to 20) where the plunger has become stuck in the standpipe when attempting to remove it for replacement. In some cases, when extreme force is applied it results in the rubber tearing from the SS plunger core. This is a result of corrosion or iron build up on the inside of the standpipe which reduces the inside pipe diameter. We have decided to take this as an opportunity to make a change for the better and is the ultimate reason for the change to the 7/8” valve body bore and plunger.

Yard hydrants installed in highly corrosive environments or in high iron content areas for extended periods of time, results in build up, scale or iron deposits on the lower end of the standpipe. This makes the removal of the plunger difficult due to the reduced bore, eliminating the clearance between the outside of the plunger rubber and the inside diameter of the pipe. The reduction of the valve body bore from 1” to 7/8” has increased the clearance from 0.021” to 0.088” around the entire circumference, a 319% increase in clearance!

Yard hydrants installed in highly corrosive environments or in high iron content areas for extended periods of time, results in build up, scale or iron deposits on the lower end of the standpipe. This makes the removal of the plunger difficult due to the reduced bore, eliminating the clearance between the outside of the plunger rubber and the inside diameter of the pipe. The reduction of the valve body bore from 1” to 7/8” has increased the clearance from 0.021” to 0.088” around the entire circumference, a 319% increase in clearance!

VALVE BODY CASTING - CHANGE # 7

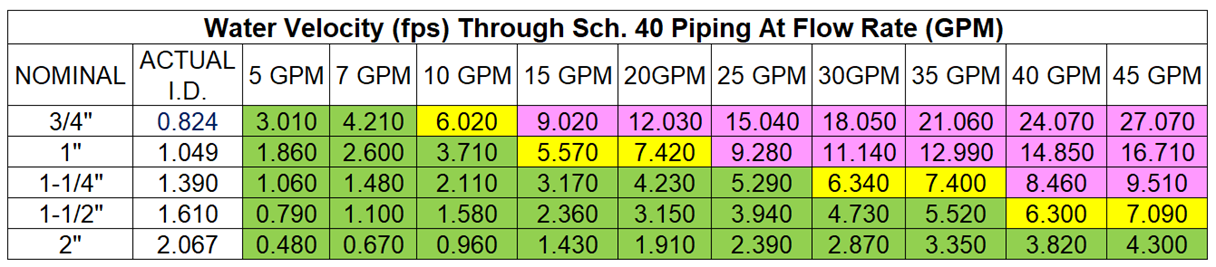

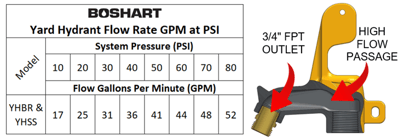

The valve bodies will only be available with a single, universal 3/4” FPT inlet connection. The 3/4” high capacity and the 1” high capacity valve bodies have been discontinued. Why? After careful evaluation it was determined that the new 7/8” bore valve body with the 7/8” diameter plunger provides more than enough flow and outperforms all the yard hydrants we have evaluated. Furthermore, the additional flow capacity of the high capacity models far exceeds the capacity of the pressure systems and pumps that provide the water. The vast majority of water pumps will only supply 7-10 GPM. Both the YHBR and YHSS hydrants with a ¾” FPT connection are capable of supplying up to 44.2 GPM. This is beyond the velocity at which water is to travel through a piping system. To put this in perspective, you would need to supply the yard hydrant with a service line of 1-1/2” or 2” diameter to maintain the recommended flow velocity.

The chart below shows that a 1” supply line should only be used to supply 15 to 20 GPM maximum. To utilize the 44 GPM of the hydrant you would need to run a 1-1/2” line minimum. Regardless, the flow will always be reduced to the inlet size and reduced further to the port diameter. Therefore, the larger 1” connection is not serving any purpose due to the port reduction. It is for this reason that we have discontinued the 1” connections.

Note: This does not mean that there is no benefit in running a larger diameter line for transferring water long distances as the friction loss will be less. However, it makes sense to make the service line reduction at the yard hydrant using a hydrant elbow or tee with a ¾” MPT connection.

Note: This does not mean that there is no benefit in running a larger diameter line for transferring water long distances as the friction loss will be less. However, it makes sense to make the service line reduction at the yard hydrant using a hydrant elbow or tee with a ¾” MPT connection.

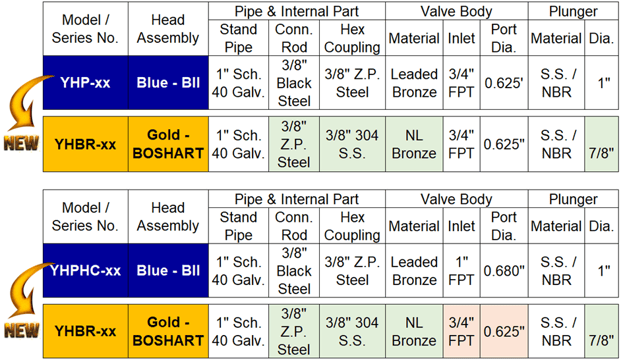

Hex Coupling & Connecting Rod– CHANGE # 8

Original YHP to New YHBR Series:

- The hex coupling has been upgraded from a zinc plated coupling to a 304SS coupling

- The connecting rod has been upgraded from black steel to zinc plated steel

- The standpipe remains the same - 1” Sch. 40 galvanized

Original YHPCR to New YHSS:

- The hex coupling has been upgraded from a zinc plated coupling to a 304SS coupling

- The connecting rod has been upgraded from black steel to 304SS

- The standpipe remains the same - 1” Sch. 40 304SS

Original YHPCRSS to New YHSS:

- The hex coupling remains the same – 304SS hex coupling

- The connecting rod remains the same – 304SS

- The standpipe remains the same - 1” Sch. 40 304SS

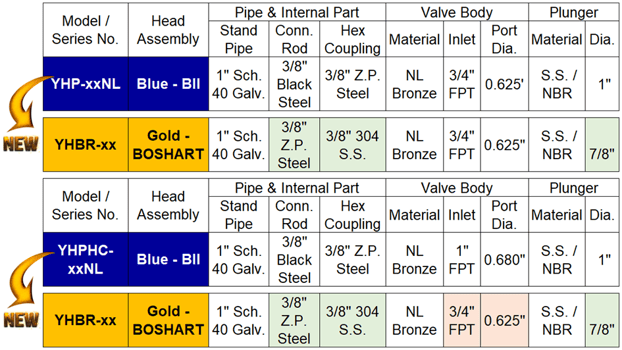

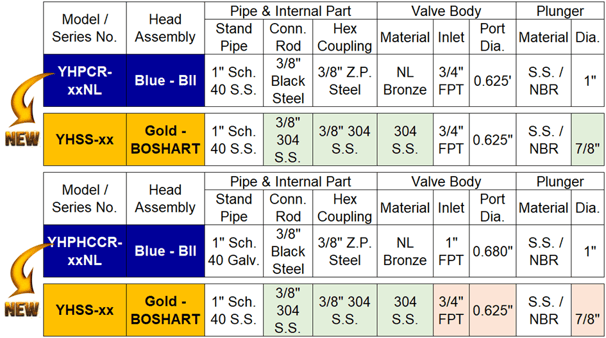

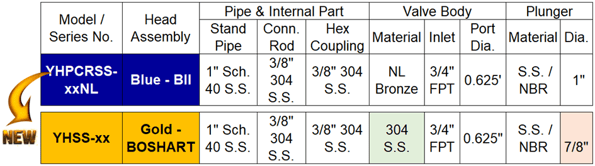

Note: See the cross refence chart at the end of the article for more detailed information.

INSTRUCTION / ACCESSORY – CHANGE # 9

INSTRUCTION / ACCESSORY – CHANGE # 9

At the request of our customers, we have included a 1/8” street elbow for the drain port connection in the installation instruction kit which also contains the SS flow position lock thumb bolt. This will eliminate the installers’ frustration when starting the installation and learning that our best practice advises installing an elbow with the opening facing downward to reduce the risk of dirt clogging the drain port. This would have resulted in having to go back and purchase the elbow separately.

INSTRUCTION / ACCESSORY – CHANGE # 10

INSTRUCTION / ACCESSORY – CHANGE # 10

Installation instructions have been upgraded to direct contractors and end users to our online Knowledge Base site where detailed installation, adjustment and repairs, and plunger replacement instructions can be found. There is also detailed information on what replacement parts are available. This upgrade is designed to reduce the number of calls to your technical support staff.

What great features have not changed on the new & improved BOSHART yard hydrant?

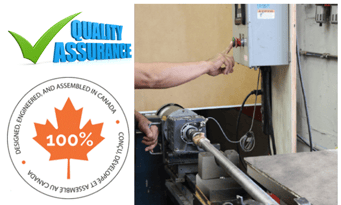

# 1 YHBR & YHSS Hydrants - Designed, Engineered, and Assembled at Boshart  Industries

Industries

Hydrant assembly is done in our manufacturing facility, located on Pacific Avenue, under strict quality control and assembly procedures. Boshart Industries has produced the extremely durable premium yard hydrant under the BII logo since its development in 2003.

The photo shows a hydrant being assembled using a custom-made power torque drive, complete with an electric eye. This assembly equipment ensures proper torque with precise alignment of the drain port on every hydrant.

# 2 Built to Last

Boshart’s yard hydrants are built to last with a heavy duty head casting, a large flow channel, and lengthened handle, ensuring ample room for a large hand and work glove to operate comfortably.

# 3 Highest Flow Rates

# 3 Highest Flow Rates

Full flow through the inlet and the sweeping bend flow passage in the head casting minimize friction loss to the large 3/4” FPT high flow spout outlet.

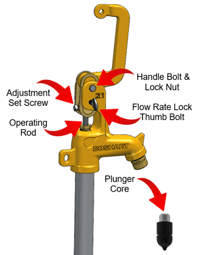

# 4 Easy to Adjust

# 4 Easy to Adjust

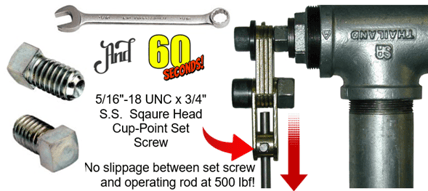

For adjustment, all you need is a 5/16” open end or adjustable wrench and 60 seconds!

The cup point set screws are very effective because the surface is rounded, and a small surface area is in contact with the shaft but does not have high stress at one point like a cone set screw. The cup point set screw holds parts permanently and is designed for hard surfaces such as the polished SS operating rod.

Holding capacity testing was performed using a tensile tester with 500 lbf. (pounds force) hanging down on the operating rod. The special SS square head set screw holds securely on the operating rod.

# 5 Smooth Operation

The operating rod and draw straps have a smooth vertical motion with minimal variance. There is minimal wear on the packing nut, operating rod, and O-rings while the competitors’ linkage systems have significant side pull on the operating rod that causes premature wear on the packing nut, operating rod, and packing.

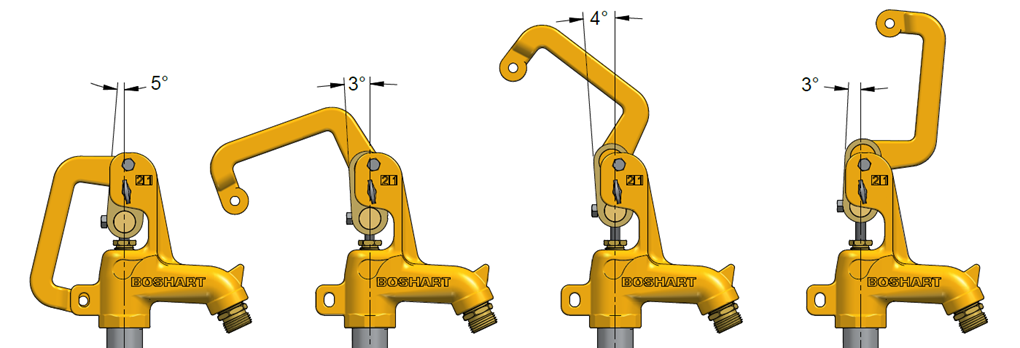

# 6 Maintained Fully Closed – Fully Open Positions

The cam on the lever takes the top of the draw strap 5° ahead of the center line. This is crucial to ensure that the system pressure forces the handle towards the closed position. This makes it impossible for the water pressure to open the hydrant. In the fully open position, the cam on the lever takes the top of the draw strap 3° ahead of the center line. This ensures that the weight of the handle does not try to close the hydrant when you want it to remain fully open (see diagram in #5 above).

# 7 Low Maintenance & Easy to Repair

# 7 Low Maintenance & Easy to Repair

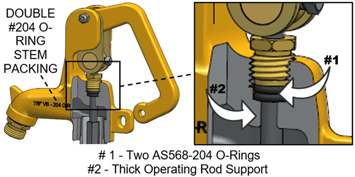

The double O-ring system seals easily. Testing on hand tightened packing nuts sealed to more than 125 PSI. Low friction = longer life! The O-rings are standard ASTM 568 Size 204 which are readily available. The casting provides a thick wall area for superior operating rod support; 2-3 times more support than the competitors.

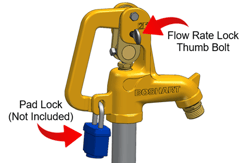

# 8 Dual Handle Locking Features

# 8 Dual Handle Locking Features

The BOSHART yard hydrants have two locking features as standard equipment. The handle can be locked with a pad lock in the closed position to prevent unauthorized use. The handle can also be locked in any position by tightening the stainless-steel thumb bolt against the draw strap to allow the operator to maintain a consistent flow rate in any partially opened position. This is ideal for throttling the flow for sprinklers or other devices when full flow is too excessive.

# 9 All Stainless-Steel Hardware

# 9 All Stainless-Steel Hardware

All stainless steel for longer life!

- Handle bolt and nut

- Set screw

- Operating rod

- Flow rate locking thumb bolt

The plunger has a SS core on the inside. It has 3 grooves to ensure the rubber is molded securely to the insert, making it impossible to pull the threaded metal insert from the rubber under normal operating or repair practices.

The new 7/8” O.D. plunger rubber has the same LUB-Groove to provide lubrication between the plunger and the valve body as the plunger is moved up and down during the opening and closing of the hydrant, which reduces wear. The flow diversion tip which reduces turbulence has also remained unchanged.

# 10 Quality Standpipe

# 10 Quality Standpipe

ASTM A53 Schedule 40 galvanized standpipe is used on the YHBR Series and Sch. 40 304 SS standpipe is used on the corrosion resistant YHSS models.

Cross Reference – ORIGINAL to NEW

Additional Resources:

https://support.boshart.com/how-do-i-install-a-boshart-yhss-series-yard-hydrant-1

https://support.boshart.com/how-do-i-install-a-boshart-yhbr-series-yard-hydrant