How to Adjust or Repair a Boshart YHBR or YHSS Series Yard Hydrant

In this article, we will look at how to adjust and repair a Boshart yard hydrant.

Yard Hydrants are frost-free and are great for getting water to remote locations that need it year round. In this blog, we are going to go over some of the common adjustment and repair procedures including:

- Section#1 - Yard Hydrant will not Shut-off Completely

- Section #2 - Yard Hydrant is Leaking at the Stem Packing

- Section #3 - Replacement of Yard Hydrant Head

- Section #4 - Replacement of Yard Hydrant Plunger

Section #1 -Yard Hydrant will not Shut-off Completely

Over time the rubber plunger will wear and it may be necessary to adjust the hydrant. While it is rare that a new hydrant will leak, there is from time to time a case where the hydrant will lose its factory setting. There is no need to panic the hydrant is not defective!

If the hydrant will not shut off completely, there are a few simple steps to adjust the hydrant linkage to its proper closing position.

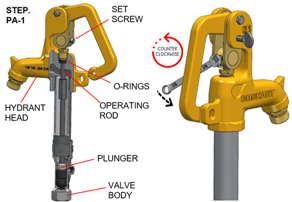

Step PA-1

Step PA-1

The plunger in the valve body at the bottom of the hydrant can be lowered by raising the point of contact of the square head set screw on the S.S. operating rod.

Using a 5/16” wrench, loosen the square head bolt so the handle can be moved up and down freely without moving the operating rod.

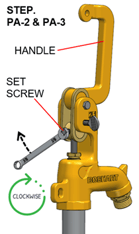

Step PA-2

Step PA-2

Lift the handle to the fully open position.

Step PA-3

Tighten the square head set screw turning it clockwise.

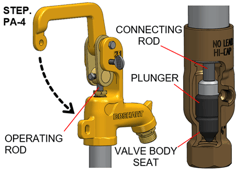

Step PA-4

Step PA-4

Apply closing pressure on the handle - this will force the operating rod, connecting rod and plunger down-wards until the plunger rubber makes contact with the valve body seat. Do not force the handle down, when the handle stops moving you have positioned the plunger against the valve body seat. STOP!

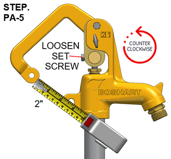

Step PA-5

Step PA-5

Set the closing pressure – To do so you must loosen the square head set screw again, allowing the handle to be moved up and down freely without moving the operating rod. – DO NOT MOVE THE OPERATING ROD FROM POSITION IN STEP #4

Position the handle so that there is approx. 2” between the handle and the locking tab on the head casting.

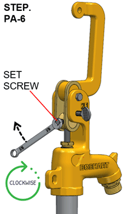

Step PA-6

Step PA-6

Then using a 5/16” wrench, tighten the square set screw so that it grips firmly on the operating rod to ensure it will not slip and loose adjustment. This will ensure the closing of the handle will force the operating rod downward and apply the pressure on the plunger to close and shut off the water supply at the valve body port.

Section #2 - Yard Hydrant is Leaking at the Stem Packing

The brass packing nut has been factory adjusted. If leakage does occur it can be easily stopped with a slight adjustment to further compress the double O-Ring seal packing.

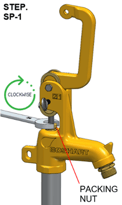

Step SP-1

Step SP-1

Simply tighten the brass packing nut by turning it clockwise in very small increments until the leakage stops using a ¾” open end wrench.

Caution: DO NOT over tighten packing nut. Excessive compression will result in accelerated wear or possible damage to the O-Rings.

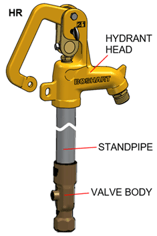

Section #3 - Replacement of Yard Hydrant Head

Section #3 - Replacement of Yard Hydrant Head

Sometimes, the hydrant head must be removed due to damages or to replace the plunger. Do not place a pipe wrench on the standpipe, it will cause damage to the factory coating. To prevent the standpipe from turning, use a strap wrench; this should also be followed when tightening.

It is VERY important that the first two steps HR-1 and HR-2 be followed carefully to avoid the potential for serious complications. Failure to do so could result in the plunger un-threading from the connecting rod which could be difficult to re-assemble, possibly resulting in the need to dig up the hydrant unnecessarily.

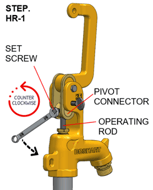

Step HR-1 (Head Replacement - Removal)

Step HR-1 (Head Replacement - Removal)

Loosen the 5/16”-18 UNC x ¾” 18.8 stainless steel set screw to allow the 3/8” operating rod to turn freely in the pivot connector.

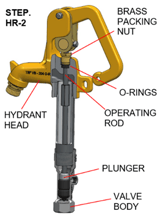

Step HR-2 (Head Replacement - Removal)

Loosen the ¾” brass packing nut until it is no longer putting any pressure on the O-ring seals. It is better to turn it out completely than to have pressure on the O-rings which could result in the operating rod turning with the hydrant head. Loosening the packing nut allows the 3/8” stainless steel operating rod to turn freely from the head casting.

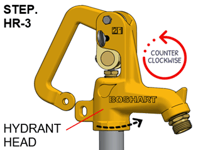

Step HR-3 (Head Replacement - Removal)

Step HR-3 (Head Replacement - Removal)

Remove the hydrant head assembly by turning the head counter clockwise (lefty loosey) using a pipe wrench (approximately 10-11 full revolutions).

WARNING! Make sure to monitor the 3/8” stainless steel operating rod while turning the head casting off the standpipe thread. The rod MUST NOT turn! If the rod turns it could unthread the connecting rod from the plunger due to the snug fit in the valve body

TIP! – Place a cloth, soft leather or rubber sheet between the pipe wrench jaws and the head casting to prevent damage to the corrosion resistant protective paint coating.

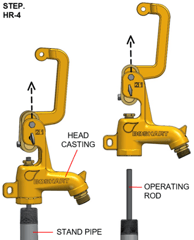

Step HR-4 (Head Replacement - Removal)

Step HR-4 (Head Replacement - Removal)

When the head casting is free from the galvanized stand pipe (YHBR) or 304SS standpipe (YHSS), pull the head casting straight up.

At this point, you would be able to fix any damage within the hydrant or fully replace the head.

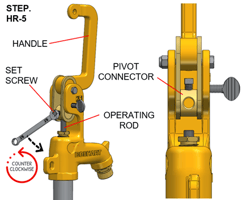

Step HR-5 (Head Replacement - Re-assembly)

Step HR-5 (Head Replacement - Re-assembly)

Make sure the 5/16”-18 UNC x ¾” 18.8 stainless steel set screw is turned out to allow the 3/8” operating rod to be inserted through the pivot connector.

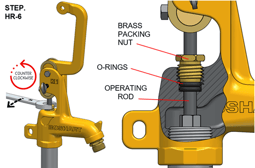

Step HR-6 (Head Replacement - Re-assembly)

Step HR-6 (Head Replacement - Re-assembly)

Make sure the ¾” brass packing nut is loosened and is not putting any pressure on the O-ring seals to allow the 3/8” operating rod to slide freely through the O-rings.

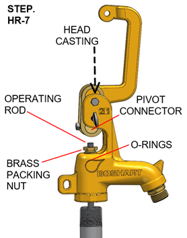

Step HR-7 (Head Replacement - Re-assembly)

Step HR-7 (Head Replacement - Re-assembly)

Apply P.T.F.E. (aka: Teflon) tape or pipe thread sealing compound to the standpipe thread. Then lower the head casting downward so the 3/8” stainless steel operating rod slides up through the O-ring seals, the ¾” brass packing nut, and pivot connector.

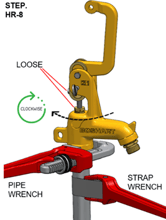

Step HR-8 (Head Replacement - Re-assembly)

When the head casting contacts the standpipe, turn the head casting clockwise engaging the threads making sure that the head threads on freely without any binding. Hand tighten, then wrench tighten using a pipe wrench approximately another 2 revolutions until the head casting is secure (righty tighty). DO NOT OVERTIGHTEN!

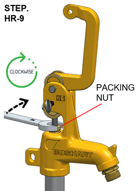

Step HR-9 (Head Replacement - Re-assembly)

Step HR-9 (Head Replacement - Re-assembly)

Tighten the ¾” brass packing nut until it is putting a small amount of pressure on the O-ring seals. Often hand tight is enough. NOTE: It takes very little compression to make a positive seal.

WARNING!

Over tightening of the packing nut can cause premature wear and damage to the O-ring seals. It is best to hand tighten at first and tighten further in small increments as required until any leakage is stopped when the water pressure is turned back on.

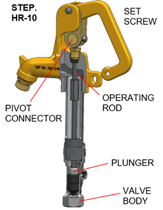

Step HR-10 (Head Replacement - Re-assembly)

Step HR-10 (Head Replacement - Re-assembly)

If the hydrant has a drip at the spout, it is not shutting off completely. You will need to adjust the hydrant setting following the steps covered in Section 1 at the beginning of this article.

When adjustment is complete tighten the 5/16”-18 UNC x ¾” 18.8 stainless steel set screw securely to the 3/8” operating rod in the pivot connector to prevent slippage of the rod which would result in the loss of the hydrant setting. NOTE: The specially cupped set screw grips very well on the rod so moderate tightening of the set screw should be sufficient.

Do not leave a hose attached to the hose bib in freezing temperatures as it may prevent proper drainage of the shut-off valve.

If a hose is attached to the hose bib of the hydrant when the hydrant is shut-off, back siphoning can occur if the end of hose is left in a container of liquid. The end of the hose must be left open to the air so the hydrant can drain back. A back flow prevent should be installed if a hose is left on during the warm summer season.

Section #4 - Replacing the Yard Hydrant Plunger

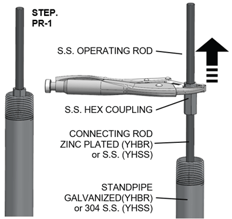

Step PR-1 (Plunger Replacement - Removal)

Step PR-1 (Plunger Replacement - Removal)

With the head casting removed, the S.S. operating rod (D) will be protruding out of the galvanized stand pipe approx. 3-1/2”.

Pull the S.S. operating rod, coupling connection rod, and plunger assembly straight up.

NEVER TWIST COUNTER CLOCKWISE, THIS COULD CAUSE THE PLUNGER TO UNTHREAD FROM THE ROD.

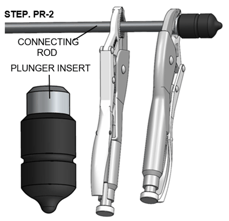

Step PR-2 (Plunger Replacement - Removal)

Step PR-2 (Plunger Replacement - Removal)

Grip the steel connection rod with vice grips just above the plunger (N). With a second vice grip securely grip the SS insert on the plunger assembly (stainless steel on newer models), then turn the plunger counter clockwise approx. 7-1/2 to 8 turns (about ½” thread) to unthread the plunger from the rod.

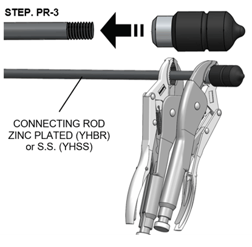

Step PR-3 (Plunger Replacement - Removal)

Step PR-3 (Plunger Replacement - Removal)

Keep a grip on the rod with vice grips just above the plunger, with the second vice grip on the stainless steel insert on the new plunger secure and turn the plunger clockwise to thread it onto the rod.

Tighten securely.

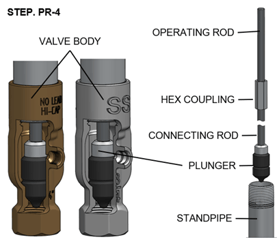

Step PR-4 (Plunger Replacement - Removal)

Step PR-4 (Plunger Replacement - Removal)

Remove both vice grips, and carefully lower the entire rod and plunger assembly (S.S. operating rod, coupling, connecting rod, and plunger assembly) straight down in the stand pipe until the plunger is pressed into the valve body against the valve seat.

NEVER TWIST THE ASSEMBLY COUNTER CLOCKWISE, THIS COULD CAUSE THE PLUNGER TO UNTHREAD FROM THE ROD!

Step PR-5

After this is complete, refer back to Section 3 of this article for installing the hydrant head. This shows how to install an existing or a new head.

If you have any further questions about these instructions, contact our Technical Support Team.

Additional Resources

https://support.boshart.com/yard-hydrant-troubleshooting-maintenance