What are hose fittings used for?

There are two major types of hose fittings: combination nipples and hose menders.

Combination nipples are made from tubular stock and are used to transition from hose to pipe, adapters, strainers, or valves.

Hose menders are used to connect two lengths of hose together or to repair a section of hose that has been damaged.

Hose fittings are designed to be used with thermoplastic and natural rubber straight end hoses. These connections should be used for fluid service only. Hose fittings are recommended for low-pressure discharge assemblies and suction service for compatible liquids such as in trash pump and discharge hose applications.

Hose fittings are designed to be used with thermoplastic and natural rubber straight end hoses. These connections should be used for fluid service only. Hose fittings are recommended for low-pressure discharge assemblies and suction service for compatible liquids such as in trash pump and discharge hose applications.

Hose fittings are not to be used with compressible gases, high pressure air, steam or any critical application as they could result in blow off. Hose fittings are not to be used with PE pipe. The smaller OD serrations may result in hose blow off.

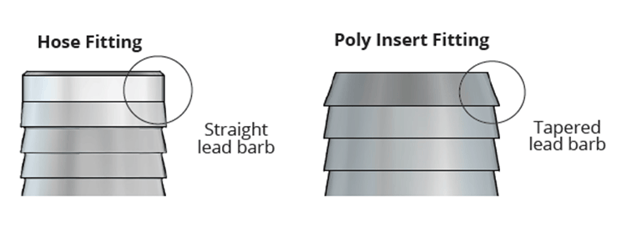

To identify hose fittings from polyethylene (PE) pipe fittings, look at the lead barb design. Hose fittings are machined with a special lead barb that makes installation into reinforced hoses easier compared to PE pipe fittings which have a tapered lead barb.

To install a hose fitting,

- Cut the hose cleanly and square to length.

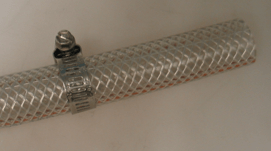

- Slide a hose clamp onto the hose.

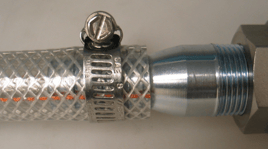

- Lubricate the hose barb and push the hose onto the barb until the hose bottoms out on the hex or shoulder.

- Position the hose clamp approximately ¼” back from the hex and tighten the clamp.

Additional Resources:

https://support.boshart.com/how-to-install-a-worm-gear-hose-clamp

https://support.boshart.com/why-wont-the-hose-fit-onto-the-combination-nipple