How to Install a Worm Gear Hose Clamp

How to Install a Worm Gear Hose Clamp:

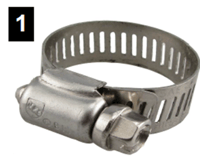

1)

1)

Select the proper size worm gear hose clamp for installation. Match the size of the clamp to the diameter of the hose it is to be secured to.

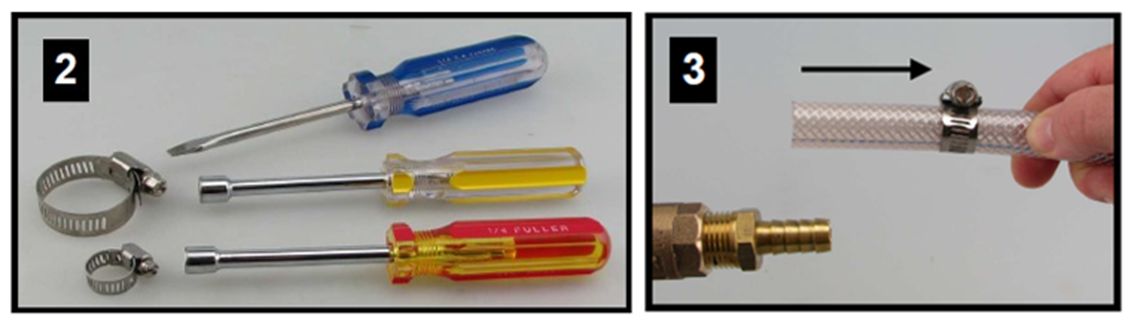

2)

Tools you need are a flat-head screwdriver or ¼” hex-head nut driver for 5/16" wide narrow band "Mini-Clamps" and a 5/16” hex-head nut driver for standard clamps.

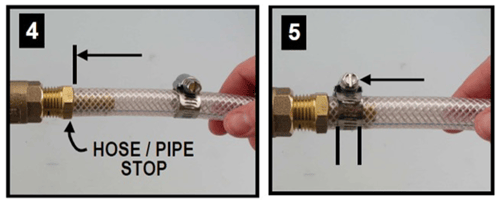

3)

Open the worm gear hose clamp by turning the head of the worm gear screw counter clockwise until the clamp can be freely slipped over the end of the hose. Slide the worm gear hose clamp onto the hose to be clamped with the worm gear screw head facing in the direction necessary for access to the hex-head with screwdriver or nut driver.

4)

Slide the hose fully onto the hose fitting.

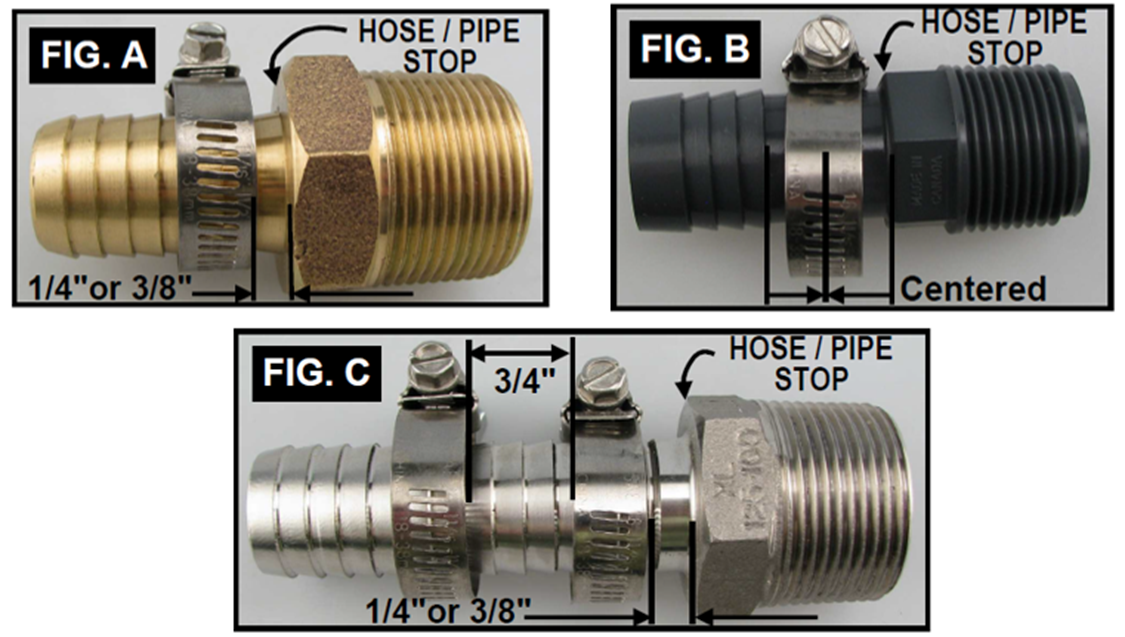

5)

Slide the clamp back up the hose and position it over the fitting serrations or barbs. For fittings with barbs the full length of the insert - place the clamp 1/4" from the end of the pipe on fittings up to 1-1/4" and 3/8" from the end on fittings 1-1/2" and larger (Figure A). For fittings with a smooth recessed area behind the barbs, center the clamp in the recessed area behind the barbs (Figure B). For fittings with extra long inserts, place the first clamp 1/4" from the end for fittings up to 1-1/4" and 3/8" from the end on fittings 1-1/2" and larger. Place the second clamp with approximately 3/4" between the bands (Figure C).

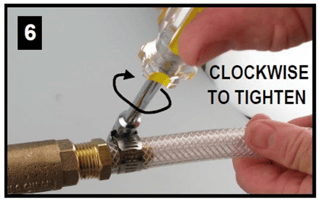

6)

6)

Turn the head of the worm gear screw clockwise to tighten using the screwdriver or nut driver. The worm gear screw meshes with the slots in the band to draw it tighter around the hose as the worm gear screw is turned.

Rated Ultimate Torque: #4 & #5 Mini Clamps is 15in.lbs. min. (1.7Nm)

Recommended Installation Torque: 10-12in.lbs. (1.1-1.4Nm)

Rated Ultimate Torque: #6 and larger Clamps is 60in.lbs. min. (6.8Nm)

Recommended Installation Torque: 35-45in.lbs (3.96-4.52Nm)

Installation Tips & Warnings

Clamps provide the highest holding pressure at the recommended installation torques. NEVER tighten clamps beyond the rated ultimate torque.

Clamps provide the highest holding pressure at the recommended installation torques. NEVER tighten clamps beyond the rated ultimate torque.

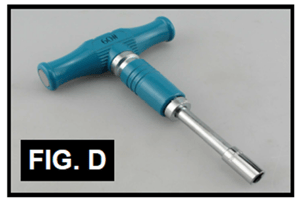

NOTE: The use of "T" nut drivers (Figure D) with a 60 in. lb. slip clutch ensures that clamps are never tightened past the ultimate torque rating.

Make sure to select the proper insert fitting for the job! Insert fittings for hoses differ from insert fittings for poly pipe.

POLYETHYLENE PIPE:

POLYETHYLENE PIPE:

The outside diameter (O.D.) of the barbs on an insert fitting designed for poly pipe is slightly larger than the inside diameter (I.D.) of the poly pipe. The reason why insert fittings for poly pipe are manufactured with a slightly larger diameter is to ensure that the Semi-Rigid Poly Pipe is stretched over the insert barbs (a.k.a. serrations). This ensures that the memory of the poly pipe while trying to return to its original diameter is compressing onto the insert barbs. This assists the clamp in making a secure, leak proof seal.

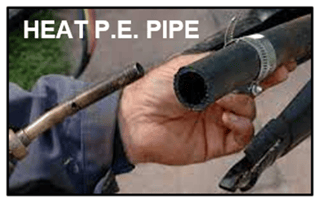

IMPORTANT: Always heat the poly pipe to make it pliable before installation. Simply place the end of the pipe into a pail of hot water (or heat with a torch). This will make the pipe more pliable and installation much easier as it also allows the clamp to more easily compress the poly pipe securely to form into the insert barbs. Visit the link below for more information.

IMPORTANT: Always heat the poly pipe to make it pliable before installation. Simply place the end of the pipe into a pail of hot water (or heat with a torch). This will make the pipe more pliable and installation much easier as it also allows the clamp to more easily compress the poly pipe securely to form into the insert barbs. Visit the link below for more information.

HOSE:

HOSE:

Hose fittings on the other hand have an O.D. that is equal to the hose I.D. to allow for installation of reinforced hoses (braided), which will not allow the hose to be stretched over the insert barbs. There is no need to stretch hoses since they are much more pliable than poly pipe and the clamps can easily compress the hose into the serrations to make a secure, leak-proof seal.

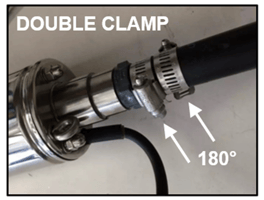

DOUBLE CLAMPING:

DOUBLE CLAMPING:

For additional holding power a second clamp can be installed on the same insert fitting provided the insert is long enough to allow for two clamps side by side. This is a practice referred to as "double clamping" (Figure C). This will greatly reduce the chance of a hose blowing off the fitting and is recommended for high pressure applications and where significant weight may be supported by the connection, such as the installation of a submersible pump on poly drop pipe. Warning: always use safety cable or rope when installing a submersible pump on poly pipe!

Additional Resources.

https://support.boshart.com/barb-o.d.-dimension-for-poly-pipe-pe-insert-fittings

https://support.boshart.com/insert-fitting-pull-off-resistance-testing

https://support.boshart.com/pressure-temperature-ratings-for-bronze-insert-fittings

https://support.boshart.com/pressure-temperature-ratings-for-304-stainless-steel-insert-fittings