What is the function of safety rope and rope hangers in a well water system?

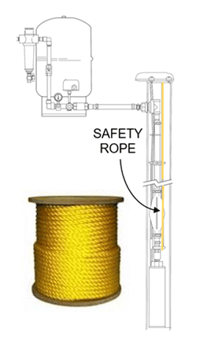

Safety rope is connected to the submersible pump and secured at the well head. Its function is to prevent pipe separation which would result in the pump being lost at the bottom of the well. It can also provide a backup means to enable the installer to pull the pump from the well in case the riser pipe were to fail or a connection was to separate. Every pump should have safety rope secured to it before hanging it in the well.

Safety rope is connected to the submersible pump and secured at the well head. Its function is to prevent pipe separation which would result in the pump being lost at the bottom of the well. It can also provide a backup means to enable the installer to pull the pump from the well in case the riser pipe were to fail or a connection was to separate. Every pump should have safety rope secured to it before hanging it in the well.

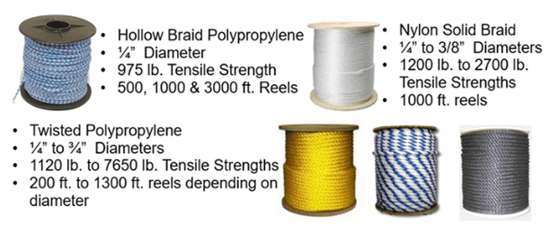

Boshart offers rope diameters of ¼” through 3/4”, with tensile strength ranging from 1120 lbs up to 7650 lbs. Rope options include braided nylon, braided polypropylene, and twisted polypropylene which are each suited for particular applications. Rope is available in different lengths and colors.

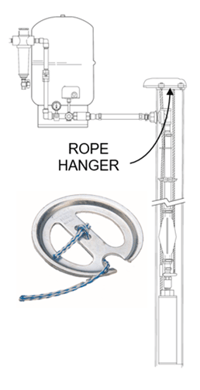

A rope hanger is installed on the top of the well casing and does not rely on the structural strength of any other well component. This allows the unobstructed installation of a well cap over the rope hanger onto the well casing. The rope hanger is easily removed from the well and set aside when the pump is being pulled from the well for service or replacement. Boshart rope hangers are designed to meet the needs of well system installers looking for an easier method of attaching the safety rope securely to the well casing at the well head, rather than fastening the safety rope to other internal components. Rope hangers are a unique item, invented by Mel Boshart, and are only available through Boshart Industries.

A rope hanger is installed on the top of the well casing and does not rely on the structural strength of any other well component. This allows the unobstructed installation of a well cap over the rope hanger onto the well casing. The rope hanger is easily removed from the well and set aside when the pump is being pulled from the well for service or replacement. Boshart rope hangers are designed to meet the needs of well system installers looking for an easier method of attaching the safety rope securely to the well casing at the well head, rather than fastening the safety rope to other internal components. Rope hangers are a unique item, invented by Mel Boshart, and are only available through Boshart Industries.

ADDITIONAL RESOURCES:

https://support.boshart.com/what-is-the-function-of-each-well-water-pressure-system-component

https://support.boshart.com/does-polypropylene-safety-rope-have-anti-bacteria-properties