What is the difference between 2- SSCxxxx and SSCxxxx worm gear hose clamps?

What is the difference between 2- SSCxxxx and SSCxxxx worm gear hose clamps?

We carry two lines of clamps. In this article we will cover the differences between the two product lines to provide you with the information you need when selecting worm gear clamps for your application.

The most popular are the 2-SSC87, 2-SSC67, and 2-SSC77 series "BII" (BOSHART INDUSTRIES INC.) clamps. The second line is the "BREEZE" product line. Both are suitable for use in standard to the toughest worm or gear clamp applications.

Construction:

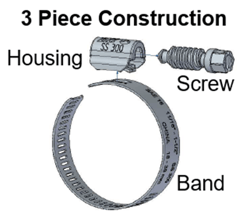

3- Piece Construction “BII”:

3- Piece Construction “BII”:

The housings of the 2-SSC series use a 3 piece, interlocked system to attach to the band. You can see that the housing wraps around the band.

The 3 piece design has the tabs of the housing curl under the band. This ensures that when the clamp is tightened, the housing tabs get held between the pipe and the band. So the tighter the clamp, the tighter the housing is being held to the band.

We believe that the 3 piece interlocking system can get a higher torque rating because of this feature. We will explain why we believe that the 4 piece interlocking system gets less torque below.

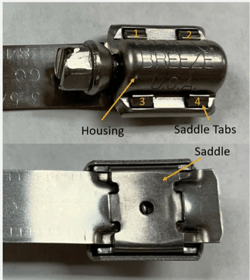

4 - Piece Construction “BREEZE ”:

”:

The 4 piece interlocking design housing is made up of two pieces: the housing and the saddle. The saddle sits under the band and holds the housing using 4 tabs.

As mentioned before, and this is only our belief, the 4 piece design can’t achieve as high of a torque rating because the pressure from tightening the clamp is transferred onto the 4 tabs. As the clamp is tightened, the pressure on the tabs makes them want to open up or bend out.

If this happens, the housing will push away as far as it can from the band. This means that the screw will lose some engagement with the band slots. This increases the chance of the unit stripping and why we think the maximum torque is lower than that of a 3 piece interlocking system.

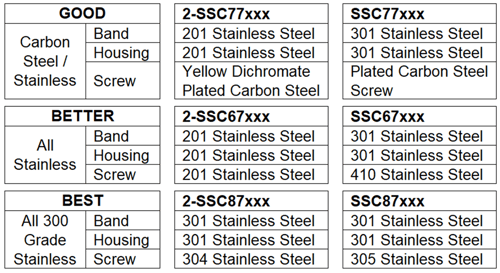

Materials:

Strength / Toughness:

Torque testing is important because it shows how much force can be applied to the band by tightening the screw before it strips or breaks. The SAE J1508 standard used for gear clamps requires clamps to achieve 50 in/lbs before breaking. As a frame of reference, an average torque that someone could apply with a standard nut driver is roughly 40 to 45 in/lbs. These are often installed with power tools or other types of socket wrenches capable of much more than that.

On the Boshart 2-SSC clamp lines, our in house torque testing results were consistently above 120 in/lbs before breaking. Boshart clamps can be used from standard to the toughest worm gear clamp applications.

Breeze clamps torque testing results, while meeting the SAE J1508 standard, consistently are in the 70 to 85 in/lbs range.

C OO – Country of Origin:

OO – Country of Origin:

The 2-SSC series clamps are manufactured in China which is in some cases an issue if a project specification mandates a USA made product. This is the reason we carry the second line of clamps.

The second line is the "BREEZE" product line manufactured in the United States. Some applications require that clamps are from the United States and we can offer clamps to appease that requirement.

Additional Resources:

https://support.boshart.com/what-series-of-gear-clamp-should-i-select

https://support.boshart.com/do-you-offer-narrow-band-mini-gear-clamps