What can I use to shrink down my heat shrink tubing?

What can I use to shrink down my heat shrink tubing?

Our heat shrink tubing is made from polyolefin material and shrinks at approximately 90°C.

Various heating devices can be used to shrink heat shrink tubing to its final size. We recommend using a heat gun where there is access to a 115-volt power source. Outdoors, where electricity may not be readily available, a battery powered heat gun is the best option, or a butane or propane torch will work.

CAUTION: When using an open flame, it must be done with great care and caution. Although the tubing itself is designed to be flame retardant, the wires themselves are not. Even a lighter can be used in a pinch, but it is not recommended.

From time to time, we get asked if a hair dryer will work. The best answer is not really. It will eventually cause the tubing to shrink, however use of a hairdryer should be avoided. It will take much longer because it is simply not hot enough to get a full shrink, especially when used on the dual wall, adhesive lined, heat shrink tubing used in our splice kits.

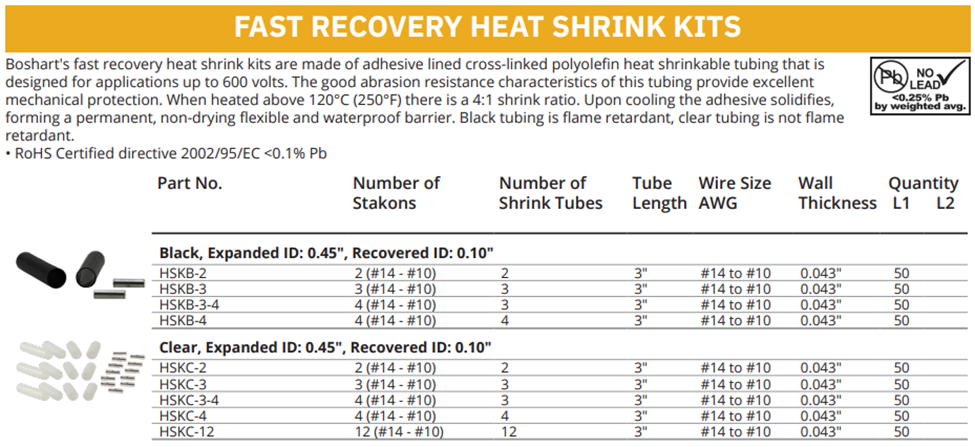

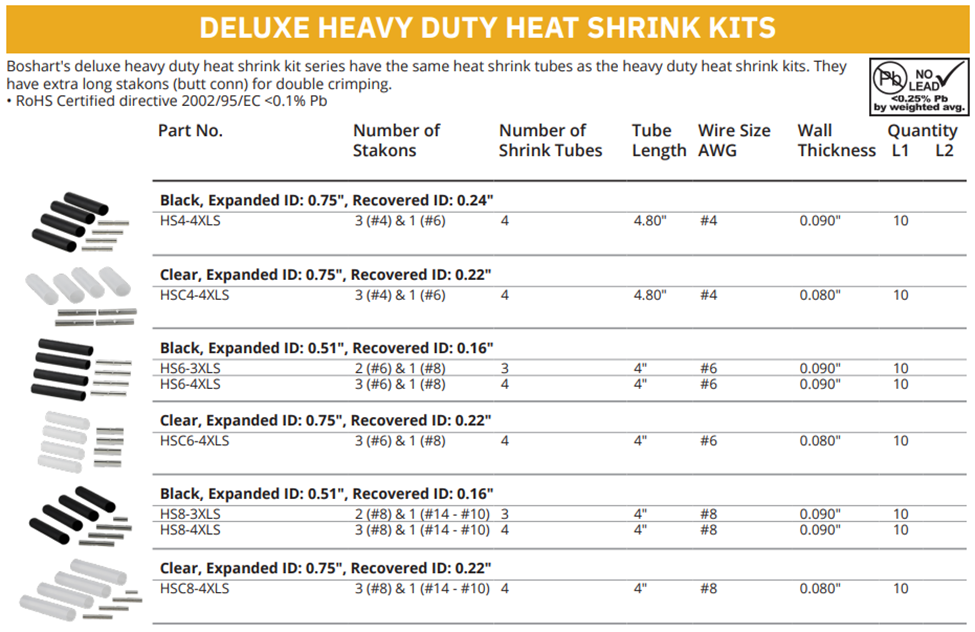

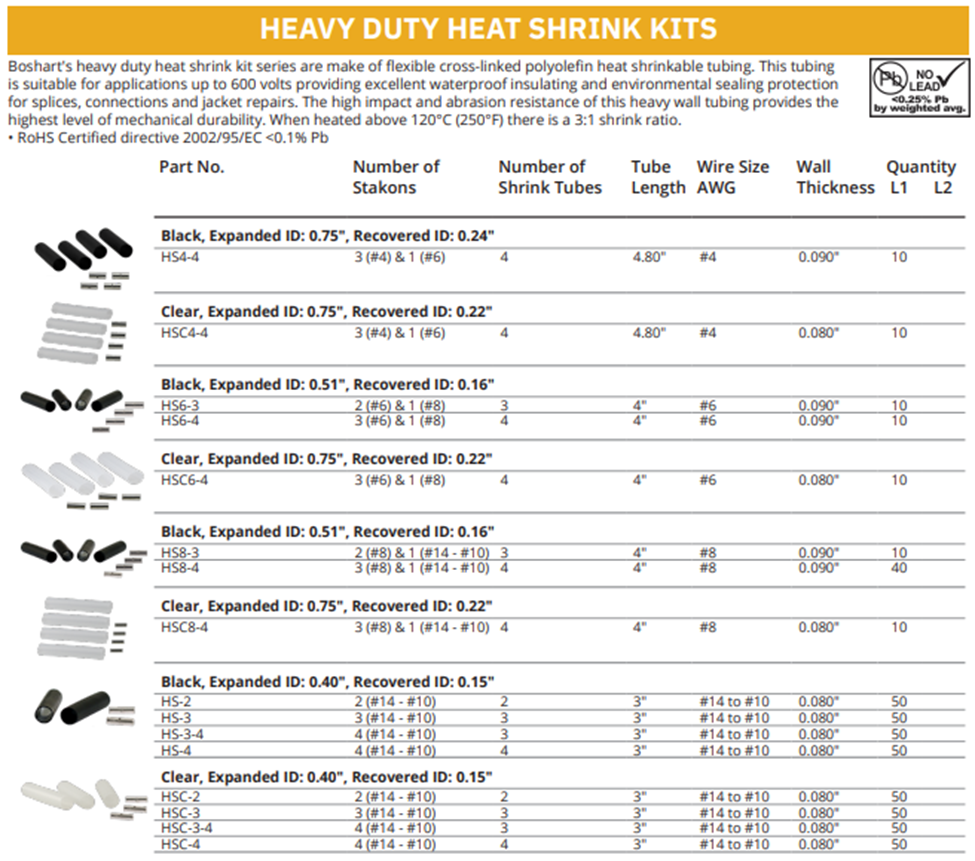

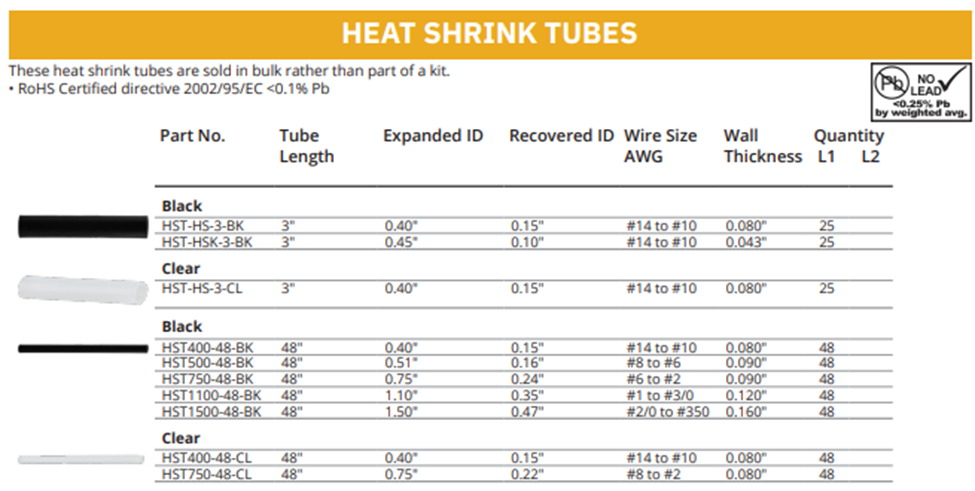

Below is a list of the heat shrink kits and 48” lengths of heat shrink tubing that Boshart offers.

Additional Resources and Articles of Interest:

https://support.boshart.com/how-do-i-select-a-heat-shrink-splice-kit

https://support.boshart.com/are-the-tubes-in-your-splice-kits-dual-wall-heat-shrinkable-tubing

https://support.boshart.com/heat-shrink-splice-kit-installation-instructions-submersible-pump-cable

https://support.boshart.com/glossary-of-heat-shrink-tubing-terminology

https://support.boshart.com/can-heat-shrink-splice-kits-be-used-in-underground-applications