What are Eight Great Features of BOSHART WSS Series Steel Well Seals?

DESIGNED WITH THE INSTALLER IN MIND!

Boshart has incorporated all of the good features from the two main suppliers of steel well seals currently on the market, #1 being Simmons Mfg. and #2 being Maass Mfg. We studied many of these seals and found quite a few problems with the design which we were able to improve on when we developed our own seals.

The following sections show some of these improvements.

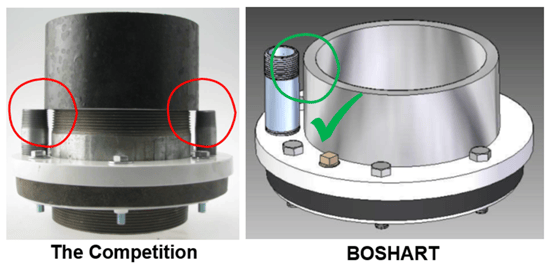

#1 Clearance for Coupling

#2 Clearance for Bolts

Below is an example of a competitor seal, you can see how the coupling rests on the bolt heads. Boshart has designed the WSS seals with clearance to allow access to the bolt heads.

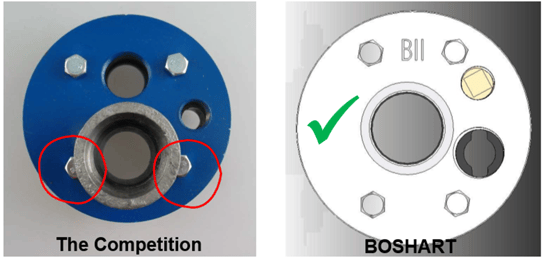

#3 Positive Seal Around Bolts

Competitors seals often have FULL thread bolts which create a spiral water passage through the rubber seal and many fit loosely through the rubber gland. Theses design issues result in failure to seal.

Boshart seals have HALF thread bolts that fit snugly through the rubber gland and provide a smooth sealing surface. This ensures a watertight seal and perfect alignment!

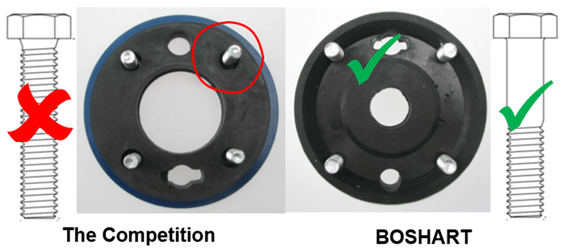

#4 Hole Alignment Protects Pump Cable Insulation from Getting Cut

You will often find seals with wire holes in the steel plates which cover ½ of the hole in the rubber seal. Other seals have wire holes which are out of alignment between the steel plates and rubber gasket seal. Both situations can cause your pump cable insulation to be cut.

Boshart seals have 100% alignment between the steel plates and rubber gaskets!

#5 Larger Conduit Tappings

Larger openings allow for the installation of flat jacketed pump cable without having to remove the protective PVC jacket.

Part No. B.I.I. Simmons Pacific Hydro

WSS4020 3/4” 1/2” 1/2”

WSS7015 1-1/4” 1” 1”

WSS8012 1-1/4” 1” 1”

WSS10040 1-1/4” 1” 1”

WSS12060 1-1/4” 1” 1”

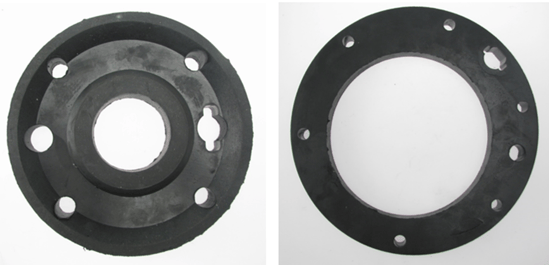

#6 High Quality Gaskets

Boshart seals use 1” thick rubber gaskets made from soft rubber for a positive seal.

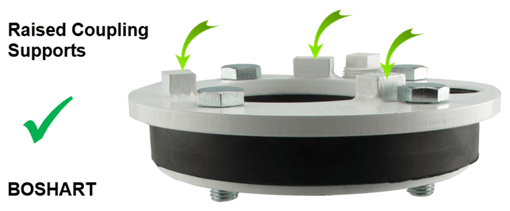

#7 Coupling Supports

The 4" x 2" and 6" x 3" HD well seals have raised supports which the drop pipe fitting rests on. This keeps the well coupling fitting above the bolt heads and conduit bushing, making it possible to incorporate a 3/4" cable hole on the 4" x 2" and 1" cable hole on the 6" x 3". This cable hole is larger than on competitors seals.

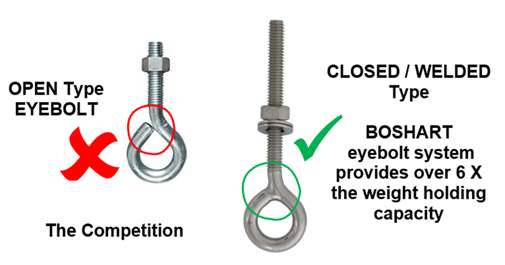

#8 EYE BOLTS – Steel Well Seals Only

Boshart uses closed or welded eyebolts which are installed through the entire seal in order to support the weight of the pump on the upper thick plate in the event of pipe failure. Testing has shown that this system is far superior to the competitions eye bolts which are often open eye bolts. These are often threaded into the thin lower plate of the seal and tests show that this method of eyebolt installation does not provide sufficient weight load holding protection.

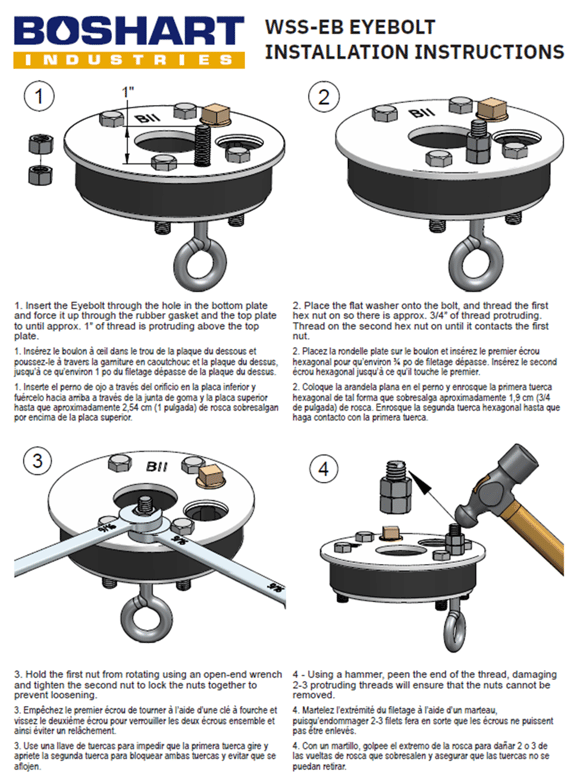

Installation Instructions

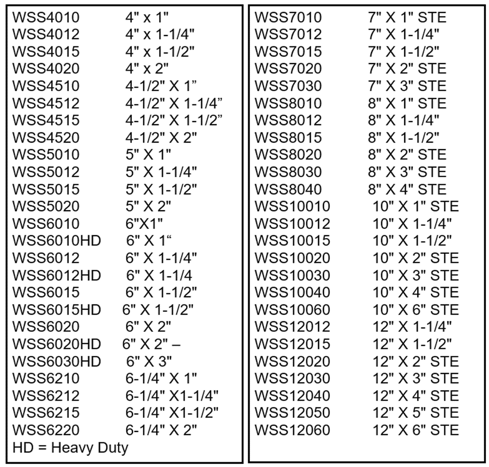

Models Available

Additional Resources:

https://support.boshart.com/why-is-the-drop-pipe-hole-on-my-steel-plate-well-seal-offset

https://support.boshart.com/are-well-seals-watertight