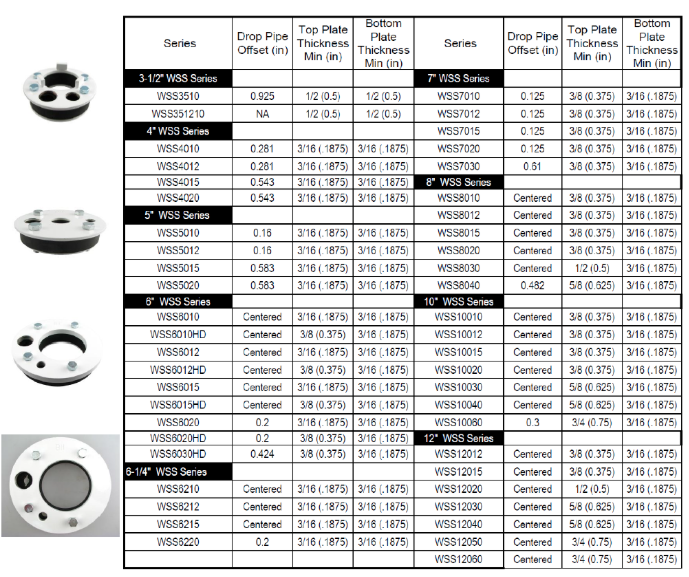

Why is the drop pipe hole on my WSS series steel plate well seal offset?

From time to time there are questions regarding the drop pipe offset on some of the WSS series, steel plate well seal. The concern being that the offset will cause issues with the pump installation down the well. In theory the concern appears to have merit, however in reality it is of NO concern.

First of all one should be aware that the use of offset drop pipes is very common by all manufacturers, offset drop pipes are necessary on smaller diameter seals with larger drop pipes to allow the seal to be design with proper vent and wire cable holes, and bolt patterns that do not interfere with the drop pipe coupling or tee installed at the well head. The majority of installers have expressed that they would much rather have off-set well seals with larger holes for pump cable and with no interference of the conduit and vent fittings, with the ability to access the bolt heads. We believe the BII well seals have the perfect balance.

In reality the fact of the matter is that the drop pipe whether steel or plastic has tremendous flexibility and when the pump is lower down the well the slight offset is of absolutely no issue. Furthermore wells are very rarely drilled "plumb" or in "perfect alignment" therefore the offset in the drop pipe will NEVER cause a problem with submersible pump installation. NOTE: A well is

within tolerance when it is off vertical by 1.2" in 100' (may vary depending on the jurisdiction), therefore in it could be argued that in the majority of installations the offset is a benefit allowing the installer to rotate the seal to compensate for the wells out-of-alignment issues and better center the pump in the well. The bottom line is that it simply is a NON-issue. These seals are installed on large and small pump installations every day without any issue.