Are Well Seals Watertight?

How to Seal a Well Seal

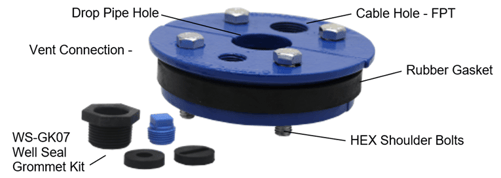

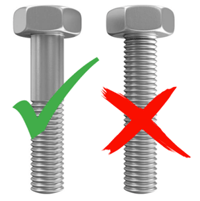

Well seals are designed to prevent surface water from contaminating the well. This is only achieved when professionally installed. A good quality well seal will provide a watertight seal between the rubber gasket and the well casing and between the drop (a.k.a. riser) pipe and the gasket. They also seal around the bolts used to compress the rubber gasket between the top and bottom plates. Note that sealing around the bolts requires that the seals use bolts with a smooth outer diameter through the gasket. Be aware of a well seal that uses bolts which are threaded all the way to the hex head. Our testing has found that in most cases surface water can channel down thru the gasket through the root of the thread profile.

Well seals are designed to prevent surface water from contaminating the well. This is only achieved when professionally installed. A good quality well seal will provide a watertight seal between the rubber gasket and the well casing and between the drop (a.k.a. riser) pipe and the gasket. They also seal around the bolts used to compress the rubber gasket between the top and bottom plates. Note that sealing around the bolts requires that the seals use bolts with a smooth outer diameter through the gasket. Be aware of a well seal that uses bolts which are threaded all the way to the hex head. Our testing has found that in most cases surface water can channel down thru the gasket through the root of the thread profile.

Beyond these sealing points is where it gets more complicated. Below we will cover two areas where the watertight question needs to be looked at in more detail.

#1 – Air Vent Connection

Water wells need to breathe so that the air can escape from the well casing when the wells water level recovers to its normal static water level after the pumping cycle is completed. It also needs to be able to draw air into the well when the pump is pumping the water level down. The air vent connection needs to have an air vent installed to both let air in and out of the well and to keep vermin from entering the well. Given the air vent has holes no well seal is watertight. Special attention must be given to wells that are in well pits, the air vent must be plumbed to ensure that the intake screen of the vent will never be submersed in water if the well pit were to get flooded with surface water in a heavy rain or flood condition.

Water wells need to breathe so that the air can escape from the well casing when the wells water level recovers to its normal static water level after the pumping cycle is completed. It also needs to be able to draw air into the well when the pump is pumping the water level down. The air vent connection needs to have an air vent installed to both let air in and out of the well and to keep vermin from entering the well. Given the air vent has holes no well seal is watertight. Special attention must be given to wells that are in well pits, the air vent must be plumbed to ensure that the intake screen of the vent will never be submersed in water if the well pit were to get flooded with surface water in a heavy rain or flood condition.

#2 – Wire (Pump Cable) Connection

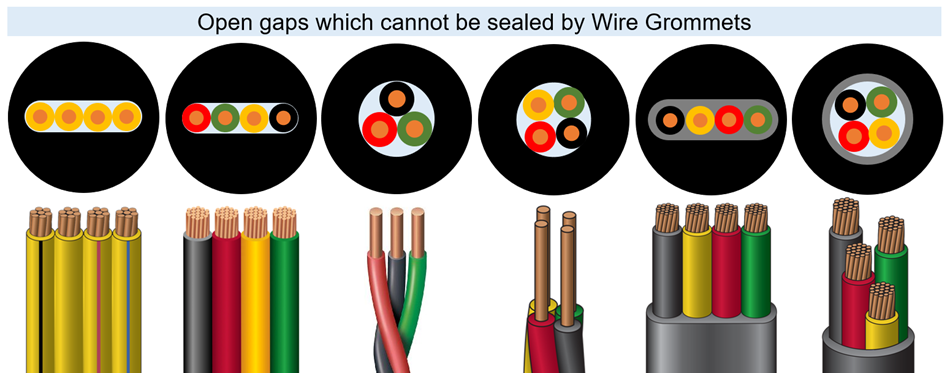

We seals are typically supplied with wire grommets. These grommet kits often come with two gaskets, one with a round hole for twisted pump cable, the other with an oblong hole for parallel pump cable or flat jacketed pump cable.

This grommet rubber when compressed will reduce the air gap between the hole in the well seal rubber and the pump cable. However, it is impossible to make a watertight seal. Compressing the wire grommet gaskets will reduce the annular spaces or gaps between the rubber gasket and the insulation on the conductors however it is not possible to make a 100% watertight seal due to air gaps into which the rubber cannot be fully compressed into or between the individual conductors. Even with rubber molded jacketed pump cables water can wick through between the conductor insulation and the rubber jacket if not 100% bonded together.

The diagrams below show the air gaps which cannot be filled.

To make a 100% watertight seal where the pump cable passes through the well seal the use of the proper grommet kit gasket will reduce the gaps, however no matter how good the seal appears it will have open passageways (air gaps) through with surface water could enter through into he well. The only way that a true seal can be made is to fill the grommet packing nut with silicone ensuring the silicone completely encapsulates the individual conductors.