How are Gas Connectors Sized?

How are Gas Connectors Sized?

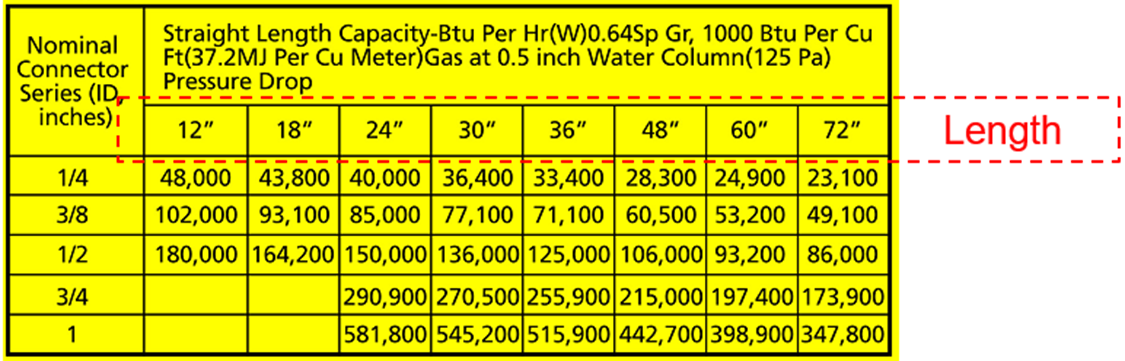

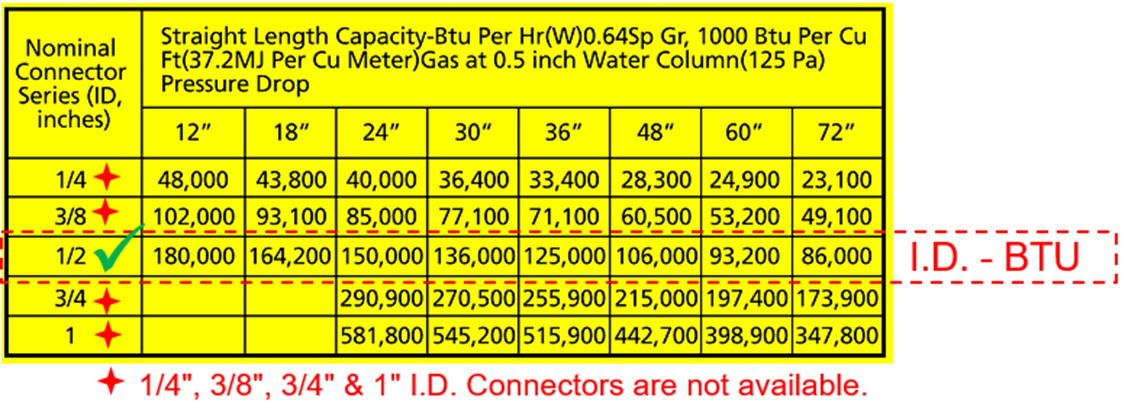

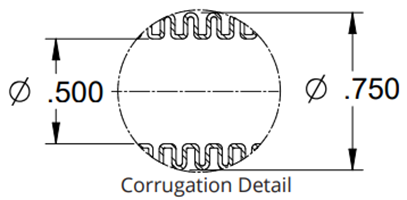

Flexible gas connectors are sized by the inside diameter (ID) and the BTU rating which is based on the length of the connector.

There is often confusion due to the connector fitting size on the ends of the flexible connector. For example, a connector with a ½” ID of the corrugated flexible tube can be supplied with either ½” MPT, ½” FPT or 3/4” MPT, ¾” FPT. Purchasing a ½” connector with ¾” fittings does not make it a ¾” connector. The BTU rating is determined by the tube I.D.

STEP #1

Determine the required length of connector by measuring the distance between the gas shut off valve and the gas connection on the appliance. Add at least 3-5 inches to that distance to allow for some movement of the appliance:

CAUTION: This is the connector length you require. Do not select a connector that is too long or too short, as this only increases the risk of damage due to kinking or bending.

CAUTION: This is the connector length you require. Do not select a connector that is too long or too short, as this only increases the risk of damage due to kinking or bending.

STEP #2

You must know how much gas is going to be used by the appliance. All gas appliances whether Natural Gas (NG) or Propane (LP) have a maximum BTU (British Thermal Unit) input that must be satisfied by the flexible gas connector. For example, a gas range requires a connector that can supply the BTU volume of gas required when all the burners and the oven are on high.

NOTE: This information will have to be obtained from the appliance supplier / manufacturer.

The BTU capacity of a gas connector changes proportionally with the ID. As the connector ID increases, the BTU rating increases. Alternatively, if the length increases, the BTU rating decreases. The larger the inside diameter, the greater volume of gas that can flow through it. However, as the connector's length increases, that maximum volume decreases due to friction loss.

Boshart only carries 1/2" ID connectors. In the chart above you will see that a ½” x 12" long connector can provide a maximum of 180,000 BTU of natural gas, while a 48" connector of the same diameter only provides 106,000 BTU. This BTU capacity chart is affixed to each of our gas connectors. This BTU chart is based on Natural Gas, but BTU capacity also depends on the type of gas being used. Natural gas (NG) capacity is always lower than liquid propane (LP) capacity. This means that the connector will provide more BTU using LP than NG. So, if the connector is suitable for NG, it will also be good for use with LP.

Boshart only carries 1/2" ID connectors. In the chart above you will see that a ½” x 12" long connector can provide a maximum of 180,000 BTU of natural gas, while a 48" connector of the same diameter only provides 106,000 BTU. This BTU capacity chart is affixed to each of our gas connectors. This BTU chart is based on Natural Gas, but BTU capacity also depends on the type of gas being used. Natural gas (NG) capacity is always lower than liquid propane (LP) capacity. This means that the connector will provide more BTU using LP than NG. So, if the connector is suitable for NG, it will also be good for use with LP.

STEP #3

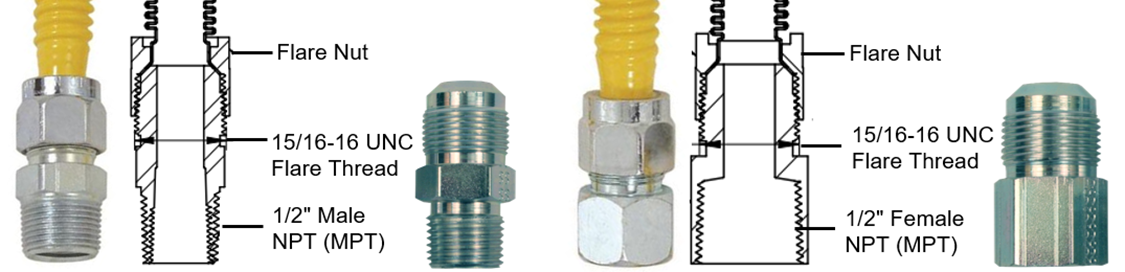

Finally, you will need to determine the proper connection type and size of the end fittings of the connector. These fitting are typically Male NPT (MPT) or Female NPT (FPT). NPT threaded connections are the same threads on plumbing valves and fittings and need to be the same size as the NPT connection on your appliance and gas supply shut off valve. This connection size should be indicated on the appliance data sheet, or you can simply match the new connector to the old connector that is being replaced.

The end fittings, as mentioned above, will have either MNPT (MPT) or FNPT (FPT) tapered pipe threads which conform to ANSI B1.20.1 standard. The other end that threads into the flexible connector is a flare connection. Flares are easily identified by the semi-conical shape and a straight UN thread.

Addition Information / Articles of Interest.

Data Sheet:

Consider poly coated “GAC” for additional protection against corrosion.

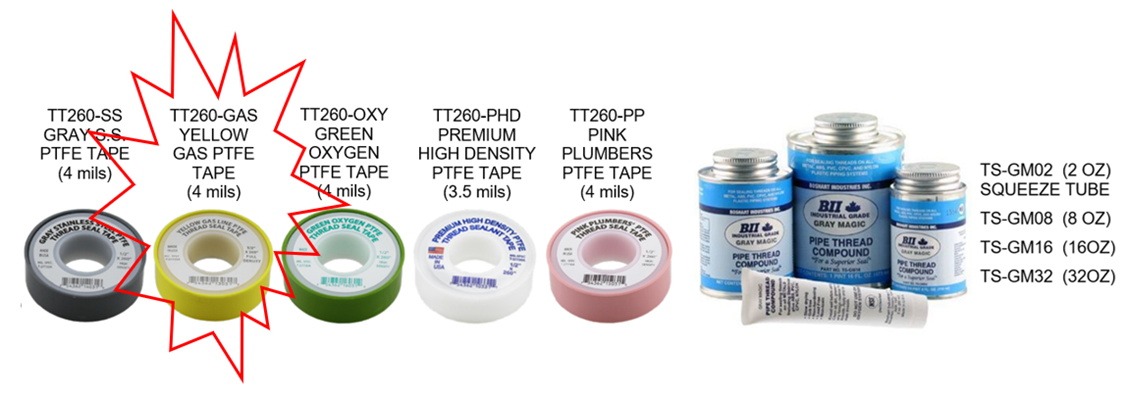

Use gas rated P.T.F.E. tape (typically yellow) or GRAY Magic thread sealing compound for the NPT connections.

https://support.boshart.com/gray-magic-applications

https://support.boshart.com/how-to-apply-ptfe-thread-seal-tape

WARNING: Do not use thread sealants on the flare connection. PTFE or Thread sealing compound will compromise the connection.

WARNING: Do not use thread sealants on the flare connection. PTFE or Thread sealing compound will compromise the connection.