What is the function of cable guards and cable ties in a well water system?

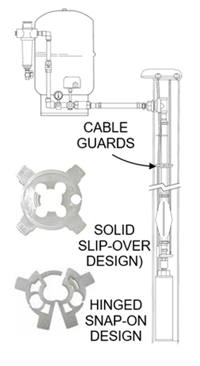

Cable guards are designed to keep the riser pipe centered in the well and to prevent damage to the pump wire. Cable guards should be placed every 15 ft. If the pump cable is not properly secured and protected, the insulation on the wires feeding the pump gets worn from rubbing against the inside of the well casing. Every time the pump, which hangs off the bottom end of 100 or 200 feet of riser pipe, stops and starts, the whole installation moves in response to the torque of the motor. This may cause the pump wires to abrade. Boshart offers two types of cable guards. The first is a low-cost solid design that must be installed over the end of the riser pipe. The second type is a self-clamping, hinged design that has a locking ratchet system which allows for the cable guard to be installed around the pipe.

Cable guards are designed to keep the riser pipe centered in the well and to prevent damage to the pump wire. Cable guards should be placed every 15 ft. If the pump cable is not properly secured and protected, the insulation on the wires feeding the pump gets worn from rubbing against the inside of the well casing. Every time the pump, which hangs off the bottom end of 100 or 200 feet of riser pipe, stops and starts, the whole installation moves in response to the torque of the motor. This may cause the pump wires to abrade. Boshart offers two types of cable guards. The first is a low-cost solid design that must be installed over the end of the riser pipe. The second type is a self-clamping, hinged design that has a locking ratchet system which allows for the cable guard to be installed around the pipe.

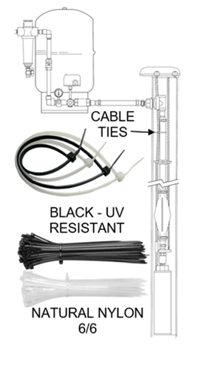

Boshart's cable ties are used to effectively secure the pump cable to the riser pipe between the cable guards. A good installation will ensure the pump cable is against the riser pipe from the bottom to the top, free of loose or looped wire. Nylon cable ties are available in natural and black colors. Either can be used for a water well installation. Natural nylon ties are less expensive but are not UV resistant, so they are not good for outdoor use. The black ties have carbon added to them which makes them UV resistant, so they can be used in both indoor and outdoor applications. Some codes require that the cable be fastened to the riser pipe at intervals no greater than 10 ft apart.

Boshart's cable ties are used to effectively secure the pump cable to the riser pipe between the cable guards. A good installation will ensure the pump cable is against the riser pipe from the bottom to the top, free of loose or looped wire. Nylon cable ties are available in natural and black colors. Either can be used for a water well installation. Natural nylon ties are less expensive but are not UV resistant, so they are not good for outdoor use. The black ties have carbon added to them which makes them UV resistant, so they can be used in both indoor and outdoor applications. Some codes require that the cable be fastened to the riser pipe at intervals no greater than 10 ft apart.

ADDITIONAL RESOURCES:

https://support.boshart.com/what-is-the-function-of-each-well-water-pressure-system-component