What is the function of a check valve in a well water system?

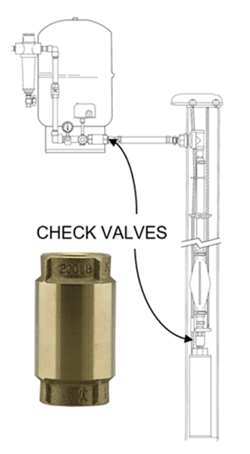

Check valves prevent water from reversing direction and draining back down the well when the pump stops. They carry the weight of the submersible pump, pipe, and the water in the riser pipe. Preventing backflow into the pump ultimately protects the pump from damage.

Check valves prevent water from reversing direction and draining back down the well when the pump stops. They carry the weight of the submersible pump, pipe, and the water in the riser pipe. Preventing backflow into the pump ultimately protects the pump from damage.

Multiple check valves absorb some of the hydraulic water shocks associated with well water pumping. This prevents damage due to water hammer which is often the cause of system failure. It is critical to follow the manufacturer’s installation instructions; failure to properly select the valve or to install it using approved system design guidelines may void the warranty.

The placement and number of check valves required for a well water system is determined by the depth of the pump in the well. Installation depth of the pump 200 feet or less requires one check valve on pump discharge and one on the surface of the well. Installation depth of the pump 200 feet or deeper may require multiple check valves at a maximum of 200-foot intervals.

In summary, the main functions of check valves in a well water system are to:

- Ensure water only travels in one direction

- Provide protection for the pump

- Absorb some of the hydraulic water shocks

ADDITIONAL RESOURCES:

https://support.boshart.com/what-is-the-function-of-each-well-water-pressure-system-component

https://support.boshart.com/how-to-install-a-submersible-pump-check-valve

https://support.boshart.com/what-is-the-cracking-pressure-of-a-17cvss-series-check-valve-1

https://support.boshart.com/what-is-the-cracking-pressure-of-a-17cvss-series-check-valve

https://support.boshart.com/what-is-the-weight-holding-capacity-for-flomatic-check-valves

https://support.boshart.com/what-is-the-cracking-pressure-of-a-flomatic-80-100-series-check-valves