Can the 0818 series brass gate valves be used for diesel fuel applications?

From a chemical compatibility standpoint, the answer is yes!

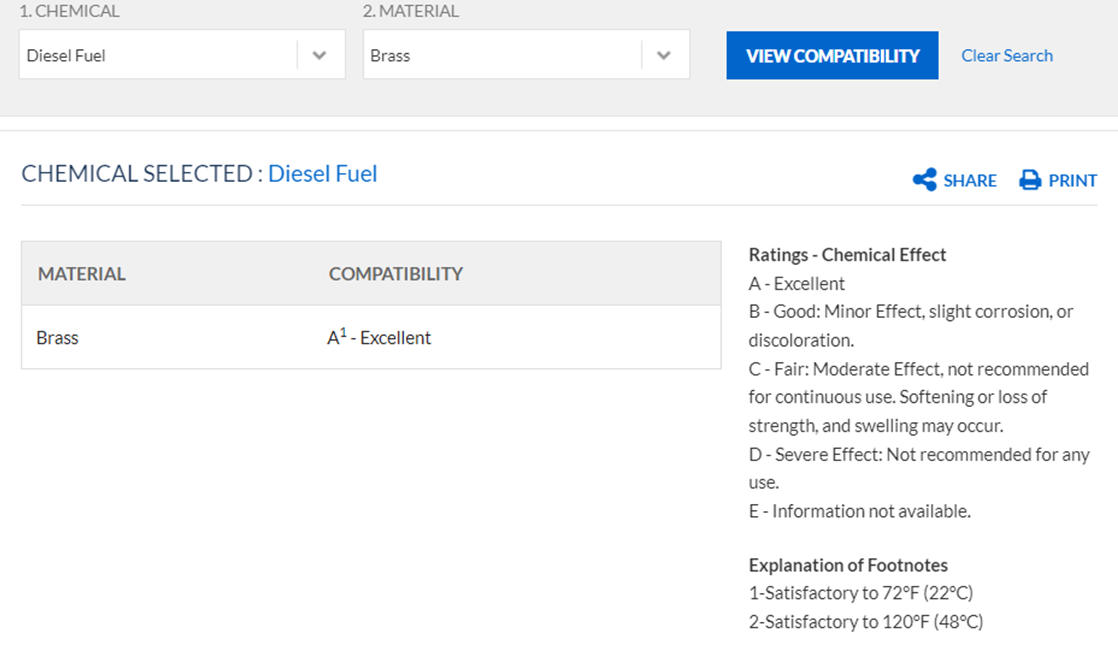

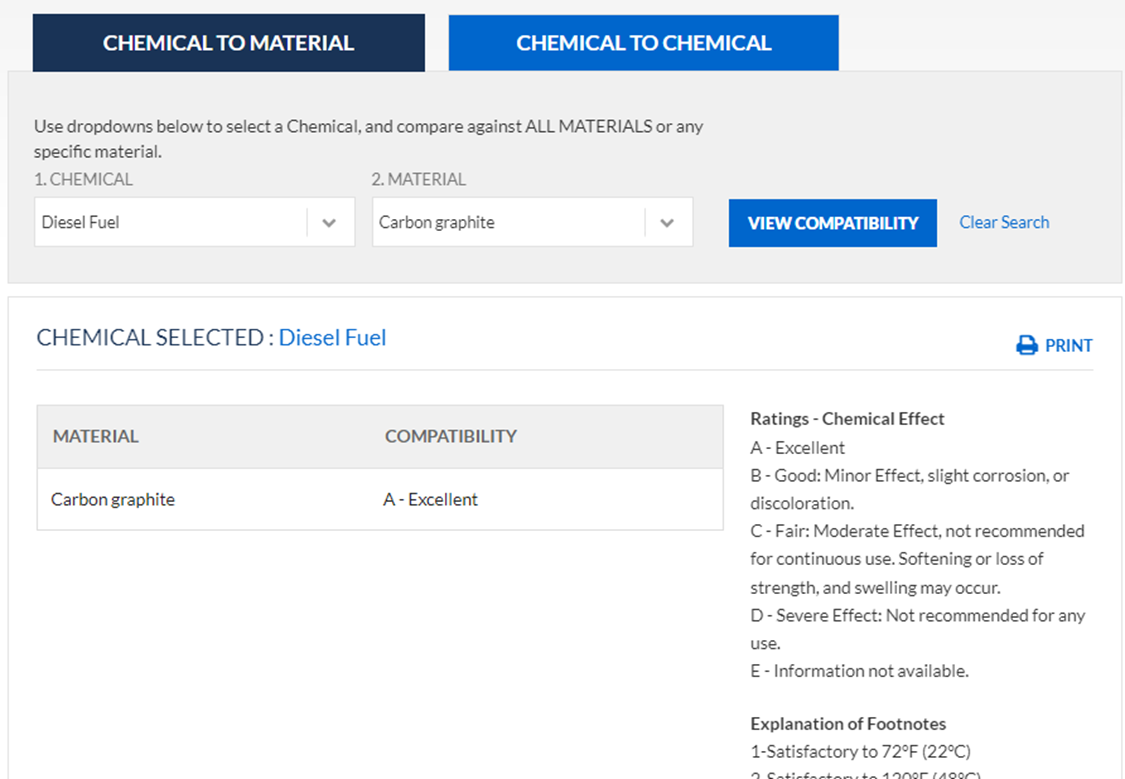

Brass and diesel fuel are chemically compatible based on chemical compatibility charts. Carbon graphite is also rated suitable.

From strictly a material suitability standpoint they will be okay. Note: These charts are to be used as a guide only!

Note: Gate valve leakage is a common occurrence in both residential water systems and industrial applications. Even the gate valves labeled as “bubble-tight” are not necessarily completely leakage-free.

SUGGESTION: Gate valves tend to provide a less reliable watertight seal than ball valves. We suggest the use of a 0827 series ball type valve over a gate type valve in a diesel application.

IMPORTANT NOTICE: The end user or installer assumes sole responsibility to ensure that the product meets all the applicable national and local codes and regulations for the project and application in which the product will be used. The AHJ (Authority Having Jurisdiction) has the final say as to whether a product or material is suitable for the project and application.

The following link to the Boshart Knowledge Base site can be used to find information regarding chemical compatibility of a wide range of materials:

https://support.boshart.com/where-can-i-find-chemical-compatibility-information

The link below will take you to The Cole-Parmer Chemical Compatibility site:

The following images shows the search results from the Cole-Parmer site for the compatibility between brass and diesel fuel and between carbon-graphite and diesel fuel:

WARNING: The information in chemical compatibility charts has been supplied to Cole-Parmer by other reputable sources and is to be used only as a guide when selecting equipment for appropriate chemical compatibility. Before permanent installation, test the equipment with the chemicals and under the specific conditions of your application.

Ratings of chemical behavior listed in this chart apply at a 48-hr exposure period. Cole-Parmer has no knowledge of possible effects beyond this period. Cole-Parmer does not warrant (neither express nor implied) that the information in this chart is accurate or complete or that any material is suitable for any purpose.

DANGER: Variations in chemical behavior during handling due to factors such as temperature, pressure, and concentrations can cause equipment to fail, even though it passed an initial test.

SERIOUS INJURY MAY RESULT: Use suitable guards and/or personal protections when handling chemicals.

Additional Resources:

https://support.boshart.com/flow-coefficient-cv-for-the-0818-series-gate-valves