Can I fix a 0818 series gate valve that will not fully shut off the flow of water?

Can I fix a 0818 series gate valve that will not fully shut off the flow of water?

Unfortunately, many years ago, gate valves were commonly installed as the water main shut off in homes across North America. Today the installation of ball valves is the norm, and they are much more reliable.

Unfortunately, many years ago, gate valves were commonly installed as the water main shut off in homes across North America. Today the installation of ball valves is the norm, and they are much more reliable.

Most often the cause of a gate valve not shutting off the water completely is due to wear of the brass gate, valve body sealing surface, and seat areas. It is common to have issues after years of service.

Another common problem is that the valve will seize and be difficult, in some cases impossible, to turn. This is due to corrosion of the thread that raises and lowers the gate. This often is caused by lack of use over many years and is much worse in areas where the water is highly corrosive.

SOLUTION:

The best solution by far is to change out the old gate valve with a new ball valve. This will provide much more reliable operation and will have a longer life expectancy.

POSSIBLE FLUSHING REMEDY:

In some cases, a gate valve will not close completely due to a build up of sediment inside the body of the valve. This sediment fills the bottom cavity of the gate valve body between the valve seats. The use of a ball valve eliminates this problem. Their construction is much different having a ¼ turn ball rather than a gate that raises and lowers inside of the valve body.

If sediment build up is the root cause for the valve not closing, one can attempt to flush out the sediment or mineral deposits which are preventing a gate from closing all the way. To flush sediment, open a faucet on a sink inside the house so there is a flow of water. Then repeatedly open and close the gate valve without asserting too much force. The common reaction is to exert additional force on the handle wheel when a gate valve will not fully close. Unfortunately using extreme force to close a valve must be avoided as it can permanently damage the valve and result in loss of water supply to the residence or commercial building.

![]() There is no guarantee that flushing will successfully remedy the problem!

There is no guarantee that flushing will successfully remedy the problem!

In some cases, gate valves can be repaired by installing a new stem and gate assembly. This requires removal of the bonnet, valve stem, and gate mechanism and then to clean the sediment out of the valve body. The problem with this is that if the threads on the valve body get damaged the valve will be rendered useless and change out of the valve will be required immediately. One should be prepared for the worst case scenario with a new valve on hand and the resources to make a change out readily available.

NOTE: Replacement parts for the 0818 gate valves are not available. The only option for replacement parts is to buy a second 0818 series gate valve and use parts from the new valve in the old. This is not a solution that we recommend.

WATER MAIN SHUT-OFF ISSUES:

#1 - In cases where only a little water continues to flow after a gate valve is closed as much as possible, plumbing repairs inside the building can be completed. This way you can avoid having the municipality turn off the water supply at the curb stop.

#1 - In cases where only a little water continues to flow after a gate valve is closed as much as possible, plumbing repairs inside the building can be completed. This way you can avoid having the municipality turn off the water supply at the curb stop.

TIP: Opening a faucet on the lowest level close to the main shut off allows a small amount of water to bleed off to a drain so it does not get forced through the piping allowing a repair to be made.

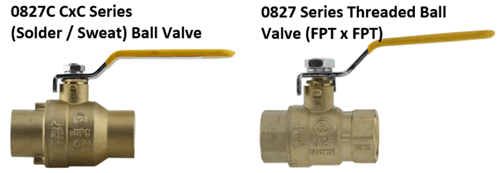

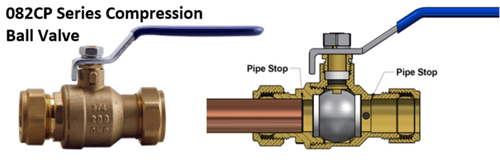

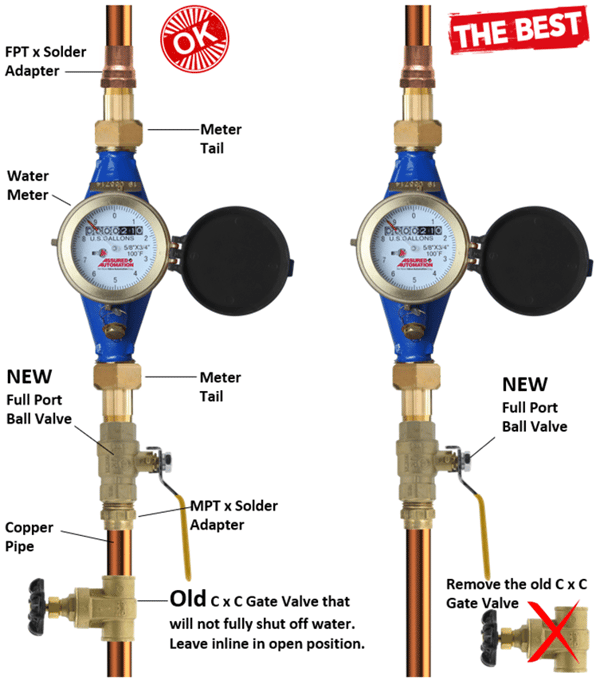

#2 – Another option that can be considered if there is a slight flow of water is to add a new second shut off right after the worn-out gate valve. This can be the easiest solution and can eliminate the need to get the water supply shut off by the municipality. It is possible if the flow is minimal, and the connections can be made “WET” meaning soldering the connections is not an option. Compression type connections may be more suitable than threaded connections.

You will shut of the water to a trickle, leave the defective gate valve in place, and install a brand new ball valve right after it. The old gate valve is opened for full flow and is no longer used. A full port ball valve allows for unrestricted flow of water, is rated higher pressures than most gate valves, has a longer life expectancy, and is less prone to failure and leaking.

CONCLUSION:

The best option is to replace the old gate valve with a new full port ball valve. It provides a much better-looking installation and rids the system of the defective valve which may cause confusion for future homeowners.

ADDITIONAL RESOURCES:

https://support.boshart.com/how-do-i-properly-install-a-compression-ball-valve

https://support.boshart.com/how-do-i-properly-install-a-threaded-ball-valve

https://support.boshart.com/how-do-i-install-a-solder-ball-valve

CAUTION: One must always make sure that the valves being used meet all the applicable national and local plumbing and building codes in your area. Ball valves are the preferred valve type for water service line shut offs and are accepted in most areas.

CAUTION: One must always make sure that the valves being used meet all the applicable national and local plumbing and building codes in your area. Ball valves are the preferred valve type for water service line shut offs and are accepted in most areas.